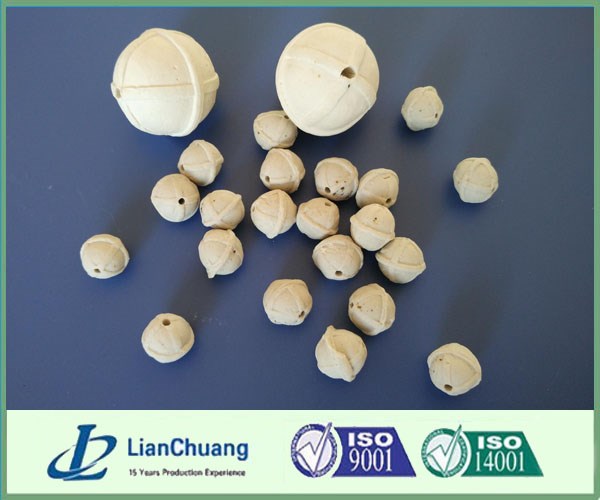

Product Description

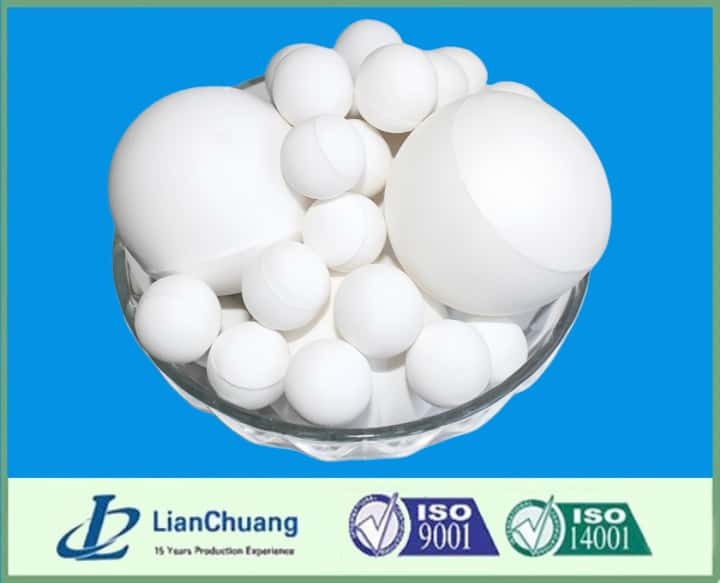

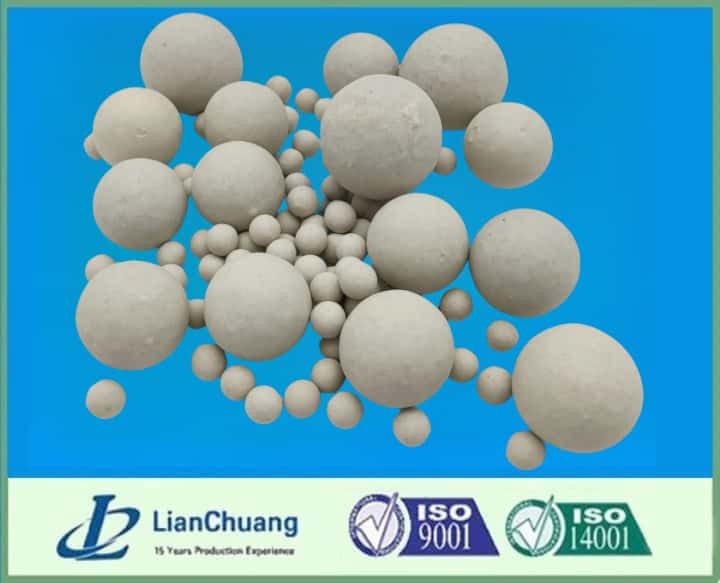

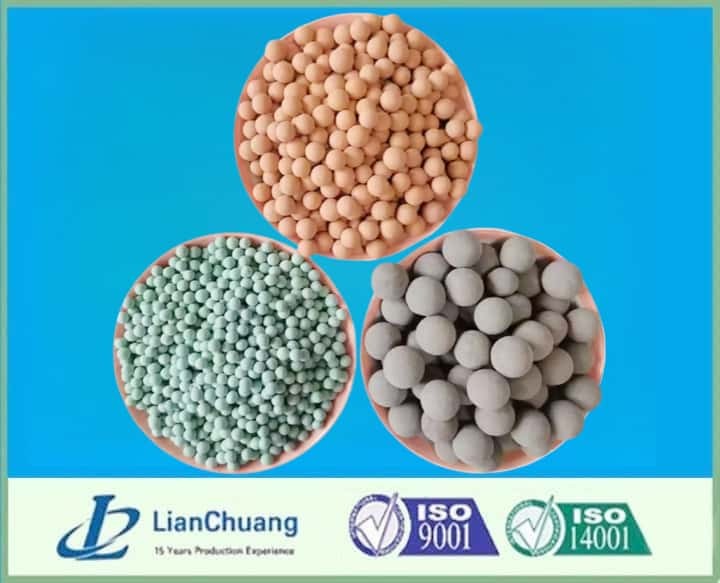

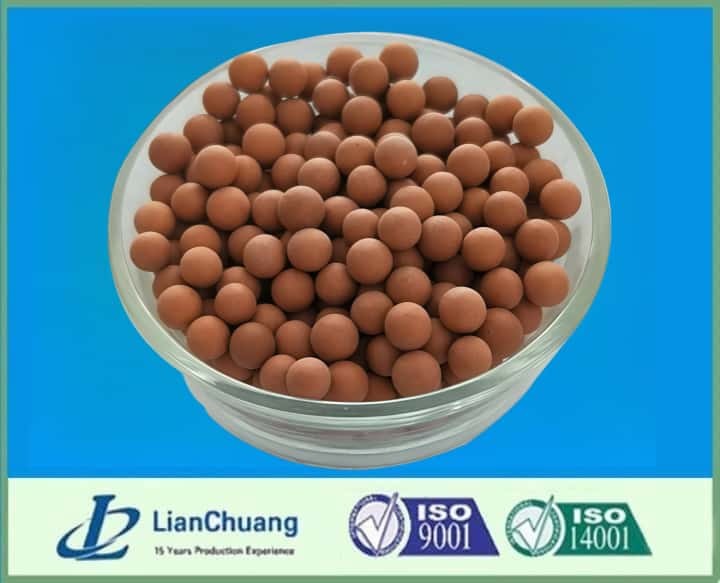

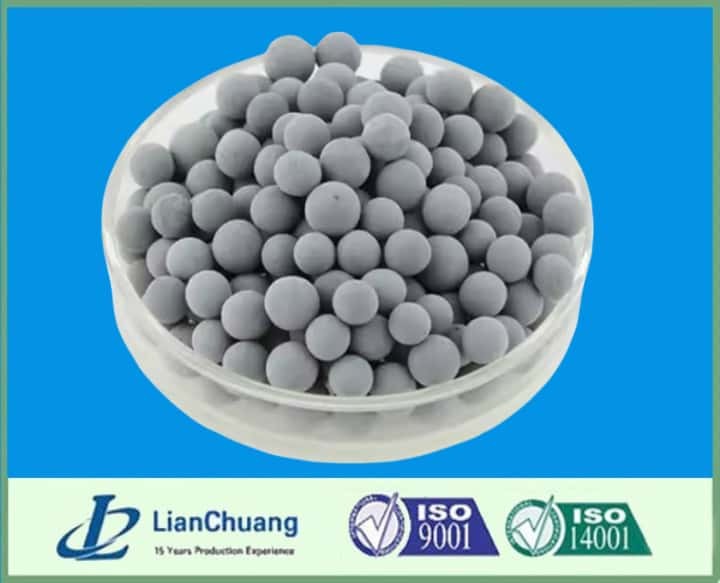

catalyst bed support media balls also known as inert support ceramic balls, it's the most widely used support media in the world. catalyst bed support media ball is commonly used to support catalyst and adsorbents products in the vessel or reactor. Catalyst bed support media ceramic balls have quite excellent stability, high mechanical strength and resistance to thermal shock, This makes them all ideal choice for support of all types of catalyst.Its main function is to act as packing material and at the same time to support the catalyst bed in order to prevent breakthrough or loss of catalyst or adsorbent materials downstream of the reactor vessels due to the high pressure and temperature inside the reactor vessels during the operation. catalyst bed support media balls could include common inert ceramic balls , middle alulmina ball, high alumina inert support ball, porous ceramic ball etc.

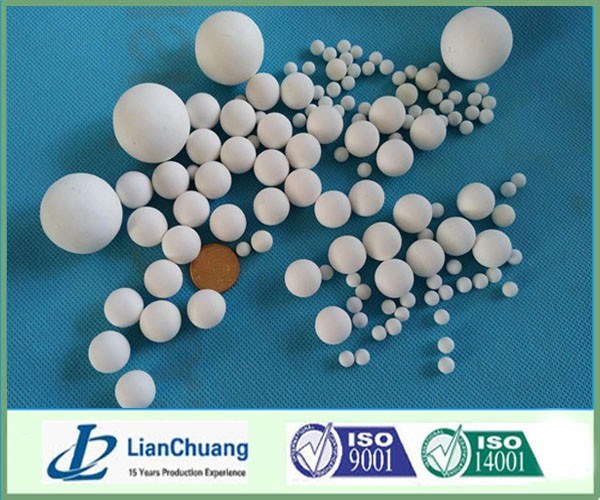

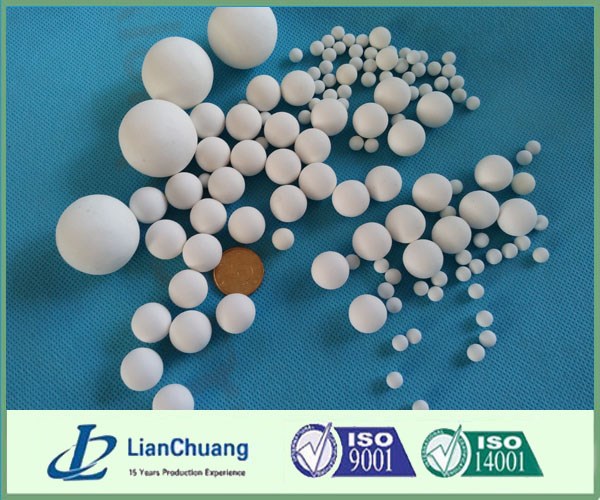

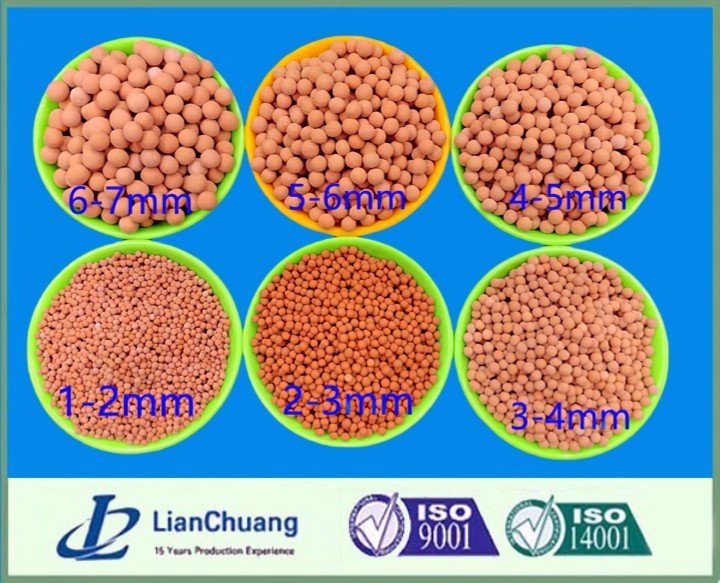

Catalyst bed support media balls ceramic ball sizes:

3 mm (1/8"),6 mm (1/4"),10 mm (3/8"),13 mm (1/2"),19 mm (3/4"),25 mm (1"),38 mm (1-1/2"),50 mm (2"),75mm (3")

Features of Catalyst bed support medias :

1. Spheres balls with different size

2. Alumina Content: 17% , 23% , 30%, 45%, 50%, 60%, 75%, 90%, 95%, 99%

3. Very excellent support and covering media.

4. Function as support media for catalyst beds or other chemical beds in reactors or towers.

5. Widely used in oil refinery, petrochemical industry, gas industry, and environmental protection.

6. Very excellent performances and stability in acid and other chemical surroundings.

7. Very good chemical stability and low rate of water absorption.

8. Can withstand high pressure and high temperatures.

9. Can also resist the chemical corrosions of any acid ( including organic and inorganic acids, but except HF acid. , most of alkali and organic solvent.

10. Will well protect the catalyst and avoid poisoned.

12. All of our balls will have shock test, attrition test, impact tast, quench test, etc. inspection.

Catalyst Bed Support Media Balls Specifications

Item | Ceramic Ball | Inert Alumina Ball | Medium-Alumina ball | High-Alumina ball | 99%-Aluminac Ball |

AL2+SiO2 | >93 | >92 | >93 | >94 | >99 |

Al2O3 | 17-23 | 23-30 | 47-56 | 90-92 | 99 |

Fe2O3+TiO2 | <4 | <4 | <3.5> | <2 | 0.8 |

CaO | <2.5 | <2.5 | <2 | <0.4 | 0.2 |

MgO | <2.5 | <1.5 | <1.5 | <0.5 | 0.1 |

K2O+Na2O | <4 | <4 | <3.5 | <0.5 | 0.4 |

Void space | 40~45% | 40~45% | 40~45% | 40~45% | 40~45% |

Materials density | 2.2~2.4 | 2.2~2.4 | 2.6~2.8 | 3.2~3.4 | 3.0~3.6 |

(g/cm3) | |||||

Water Absorption | <3 | <3 | <2 | 2~6 | 2~6 |

Bulk Density | 1.3~1.4 | 1.4~1.5 | 1.5~1.6 | 1.6~1.8 | >2.0 |

Operation Temp | >1100 | >1100 | 1480 | 1760 | 1800 |

Moh s Hardness | >6.5 | >7 | >7 | >8.5 | >8.5 |

Crush Strength | KN/particle | ||||

1/ 4"(6mm) | >0.5 | >0.54 | >0.56 | >0.44 | >1 |

1/ 4"(6mm) | >6.07 | >6.22 | >4.89 | >5.33 | >8 |

1.5"(38mm) | >8.52 | >8.92 | >5.33 | >5.28 | >8 |

2"(50mm). | >9.7 | >9.8 | >6.22 | >8 | >15 |

Size Tolerance for support media ceramic balls:

Diameter | 3mm | 6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 25mm | 30mm | 38mm | 50mm | 75mm |

Allowable Deviation | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||