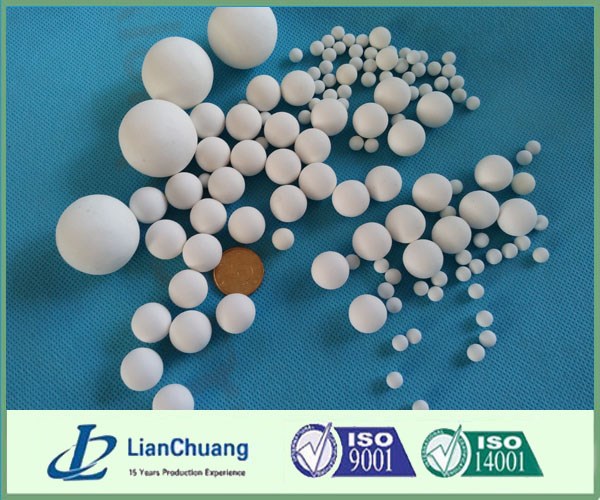

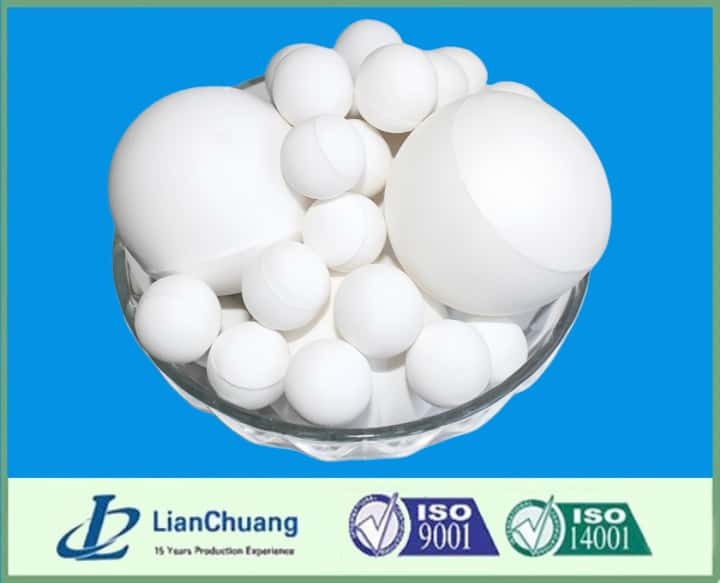

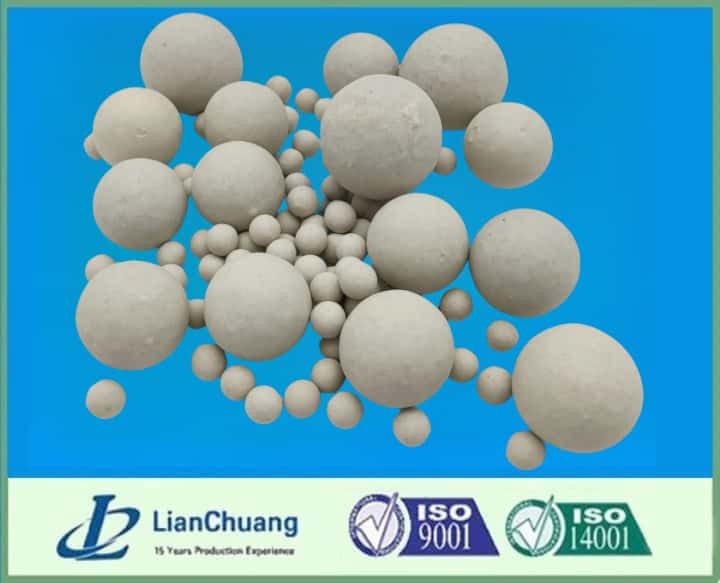

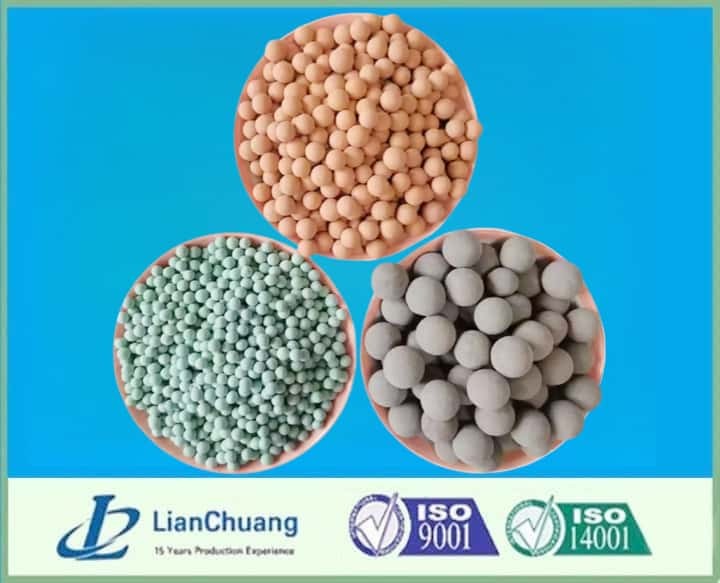

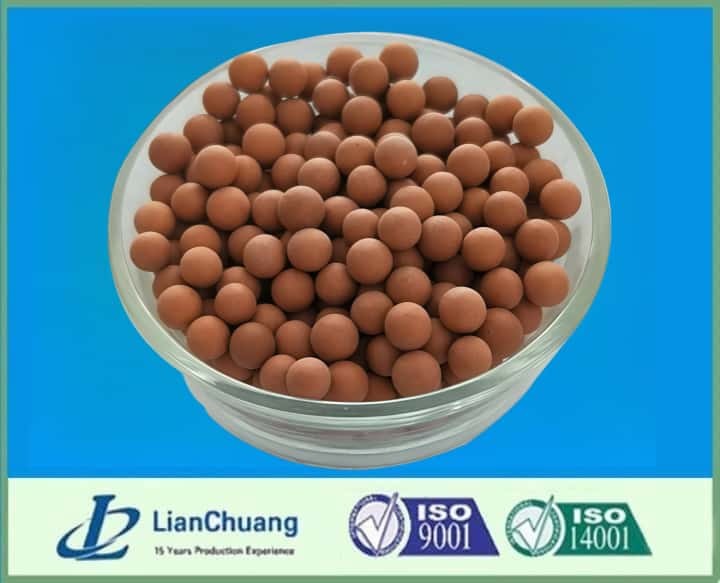

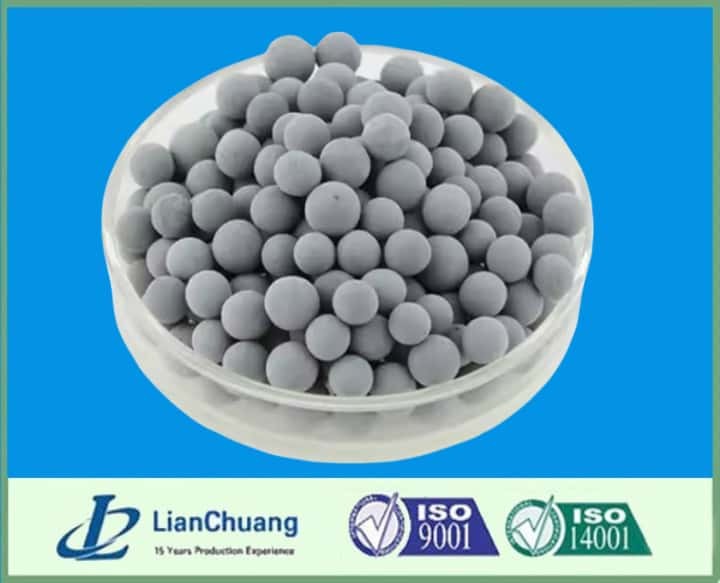

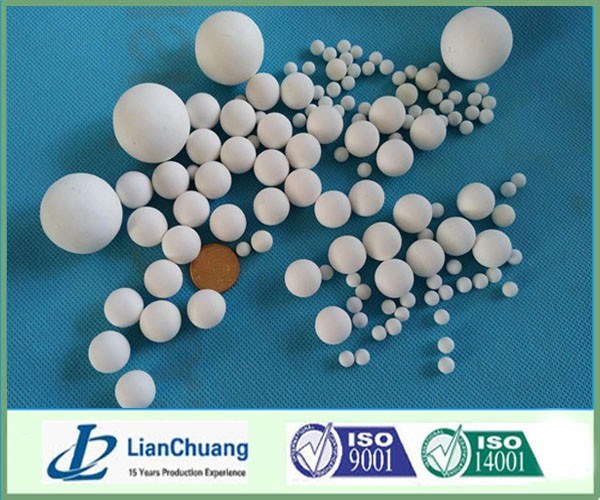

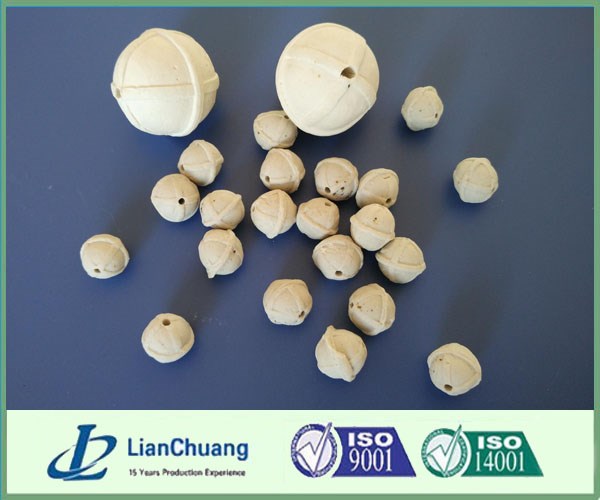

Product Description

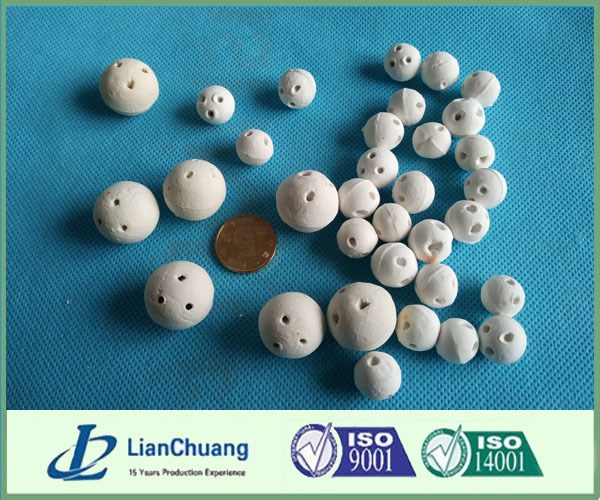

inert ceramic balls are manufactured from very high quality chemical-porcelain clay materials, which has quite excellent stability. It has the characteristics of high temperature resistance, high pressure resistance, low water absorption, high chemical stability and thermal stability. Furthermore, it is able to withstand the corrosion of acid, alkali and organic solvents, and is able to withstand the thermal shock temperature changes. inert alumina ceramic balls often used to increase the distribution spots of gas or liquid, and to support and protect the activating catalyst of low strength in the reactors and column tower.

Inert ceramic balls can be applied as catalyst, absorbent, desiccant and drying agent in petroleum, chemical, fertilizer, natural gas and environmental protection industries. As a high alumina ceramic ball catalyst reactor coverage tower packing materials and support, the major role is to increase distribution of gas or liquid, support and protect the intensity of low strength activity catalyst.

Chemical composition of inert cearmic ball:

Al2O3+SiO2 | Fe2O3 | MgO | Na2O | Other |

> 96% | <0.5% | <0.5% | <0.05% | <0.05% |

Physical property of the inert ceramic ball:

Item | Value |

Water absorption (%) | <1< span=""> |

Bulk density (g/cm3) | 1.35-2.2 |

Specific gravity (g/cm3) | >3.6 |

Operation temp.(max) (°C) | 1650 |

Moh’s hardness (scale) | >7.5 |

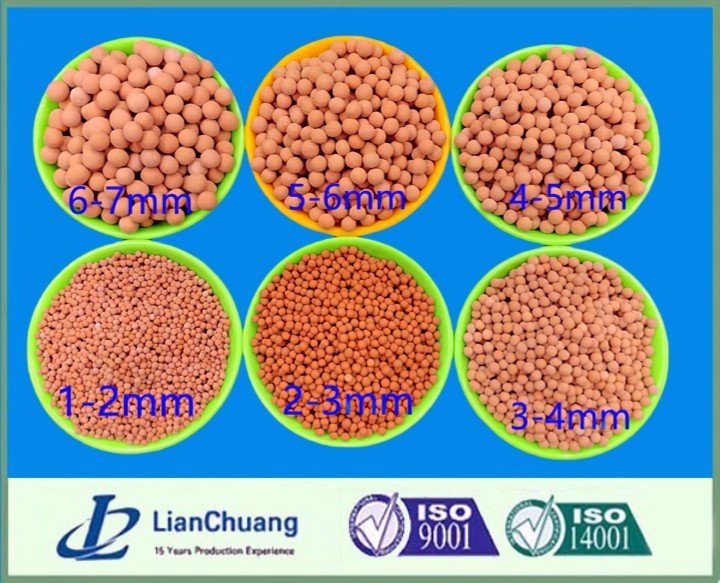

Size available & Crush strength of the inert alumina ball:

Size | KN/particle |

1/8" (3mm) | >2 |

1/4" (6mm) | >4.6 |

1/2" (13mm) | >8.7 |

3/4" (19mm) | >12 |

1" (25mm) | >16 |

1-1/2" (38mm) | >23 |

2" (50mm) | >34 |

The normal package of ceramic ball as bellows:

1. Directly by small plastic bags. (25kg/bag).

2. By big enhanced plastic bags(1MT/Bag),

3. Steel drums.

3. According to the client's requirement.

Our factory have complete production line for all kinds of ceramic balls. We can also produce products according to customers’ specification. welcome contact us for more detail.