Product Description

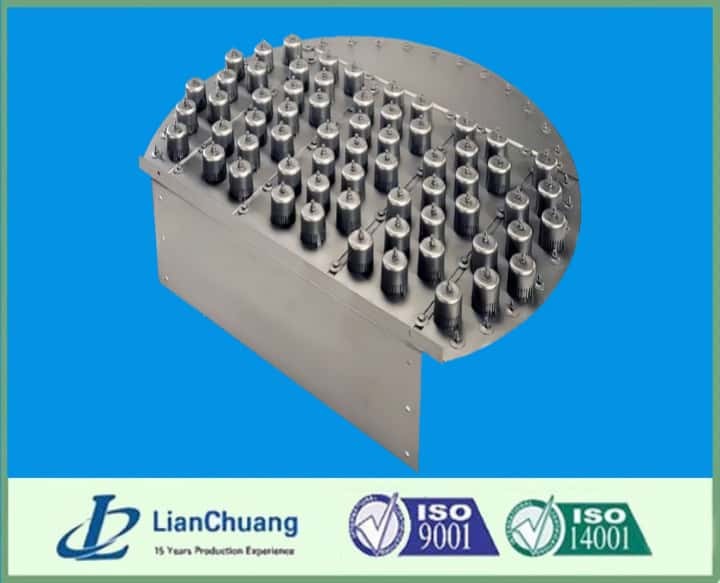

The Metal Bubble Cap Tray is is a type of tower internal designed to optimize gas-liquid interactions. It features advantages such as minimal pressure drop, extensive contact surface area, and exceptional mechanical durability. This tray type is frequently employed to enhance the efficiency of mass transfer by increasing the contact area between gas and liquid. Each tray includes chimneys or risers topped with caps, which create pathways for vapor to pass through, mix with liquid, and promote effective bubbling action.

metal bubble cap tray has a highly efficient gas-liquid mass transfer device widely used in distillation and absorption processes. It features an innovative design that ensures optimal performance, adaptability, and reliability across a range of industrial applications.

Key Components

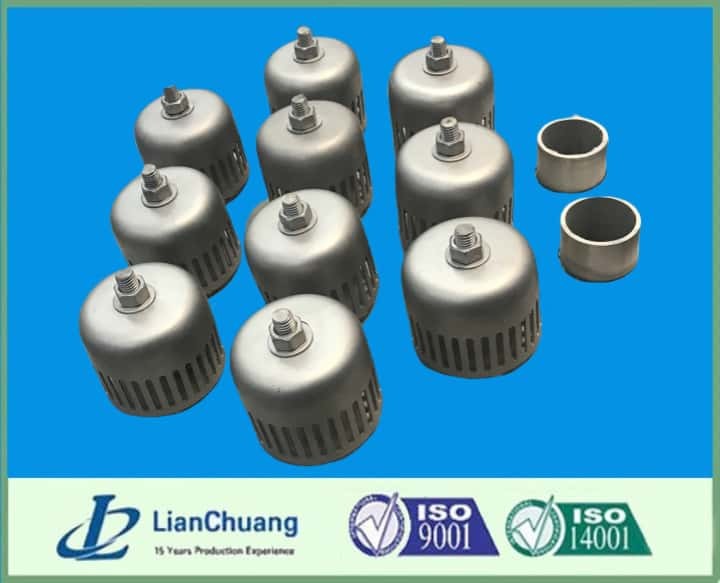

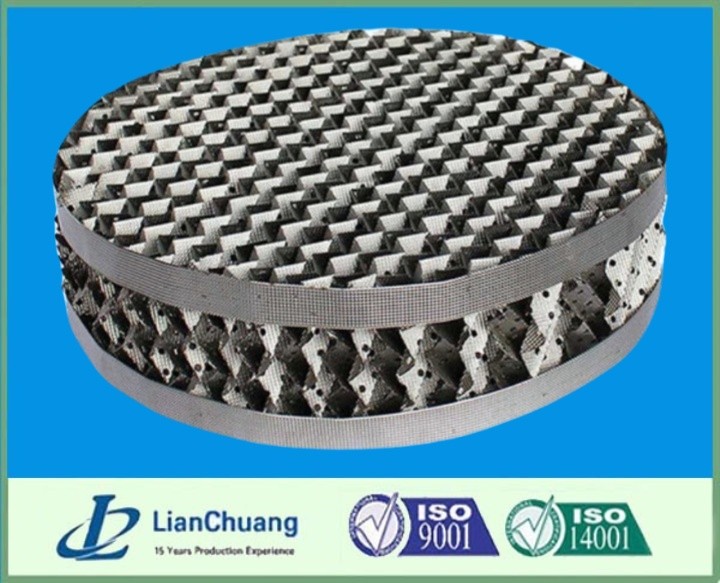

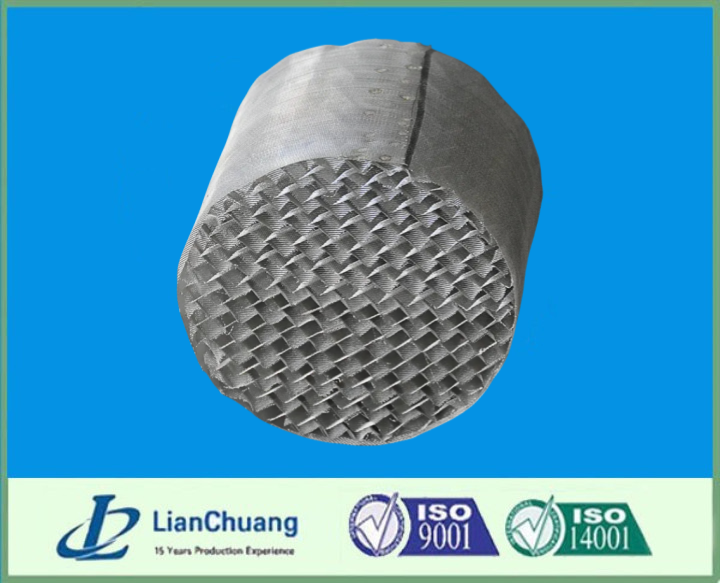

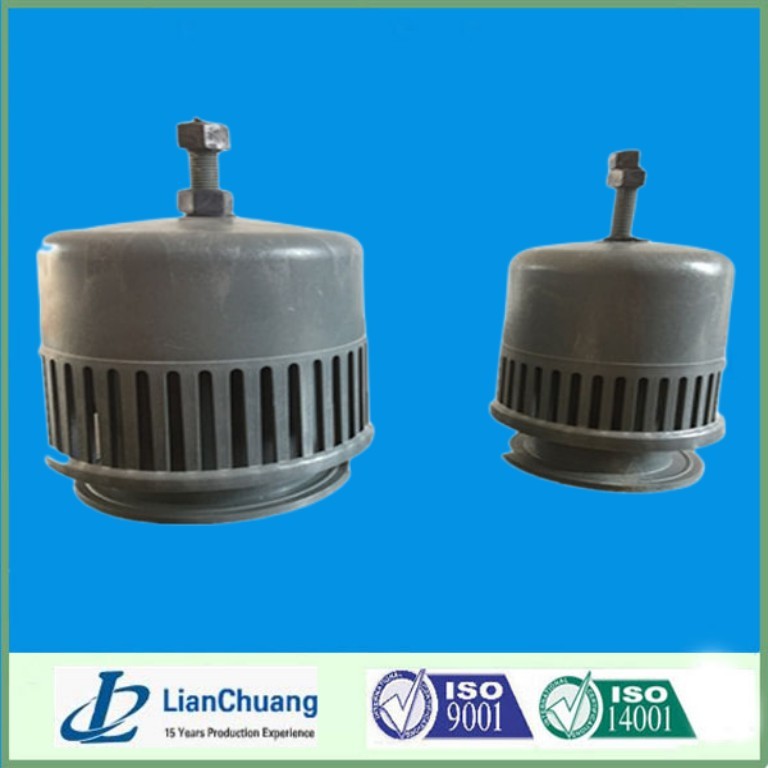

Bubble Caps: Gas-liquid contact elements mounted on the tray surface. Each cap is dome-shaped with multiple slotted openings for gas flow and mass transfer.

Riser Tubes: Short pipes welded to the tray’s perforations, facilitating gas flow to the bubble caps.

Downcomers: Channels directing liquid from one tray to the next, ensuring proper liquid distribution.

Weirs: Overflow barriers maintaining liquid height on the tray for consistent operation.

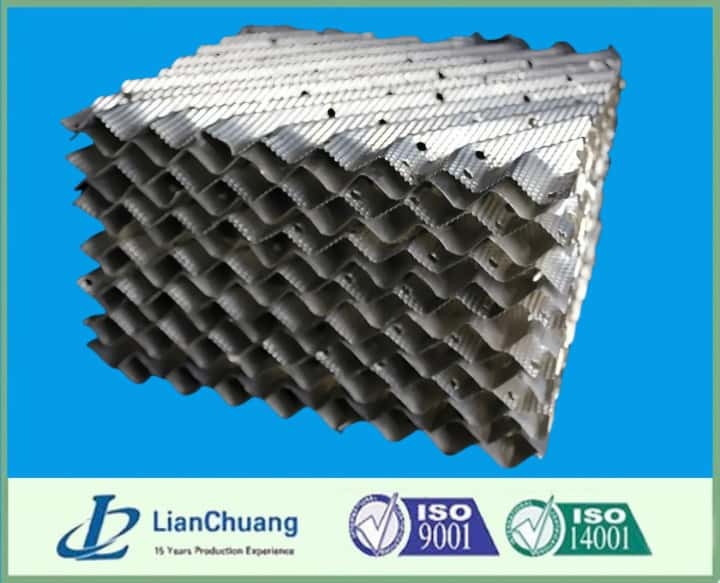

Tray Plate: The main structure supporting the above components, designed with circular holes for riser tube placement.

Features and Advantages

High Efficiency: The bubble caps provide full gas-liquid contact with a large mass transfer area, significantly enhancing tray efficiency.

Operational Flexibility: Maintains high efficiency across a broad load range, accommodating variable feed rates.

Large Capacity: Suitable for large-scale industrial production due to its high throughput capabilities.

Stability and Reliability: Resistant to clogging, adaptable to a wide range of operating conditions, and ensures stable operation.

Types of Bubble Caps

Circular Bubble Caps: Most commonly used, resembling a bell with toothed edges. The teeth can vary in shape (rectangular, triangular, or trapezoidal) to suit specific process requirements.

Strip Bubble Caps: Alternative design used for specialized applications.

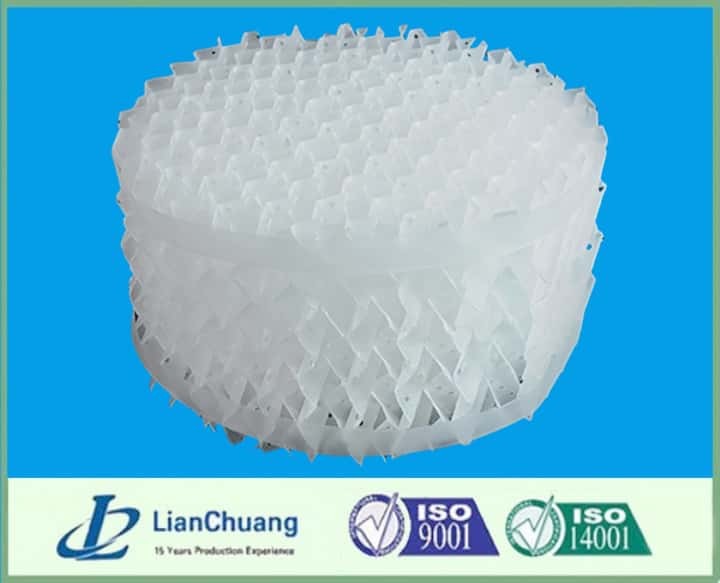

Distillation Process Workflow

1. Gas rises through the riser tubes into the bubble caps, forming foam in the liquid phase.

2. Mass transfer occurs as gas and liquid interact within the foam.

3. The gas phase exits to the tray above, while the liquid flows down through the downcomer to the tray below.

4. These steps repeat across successive trays.

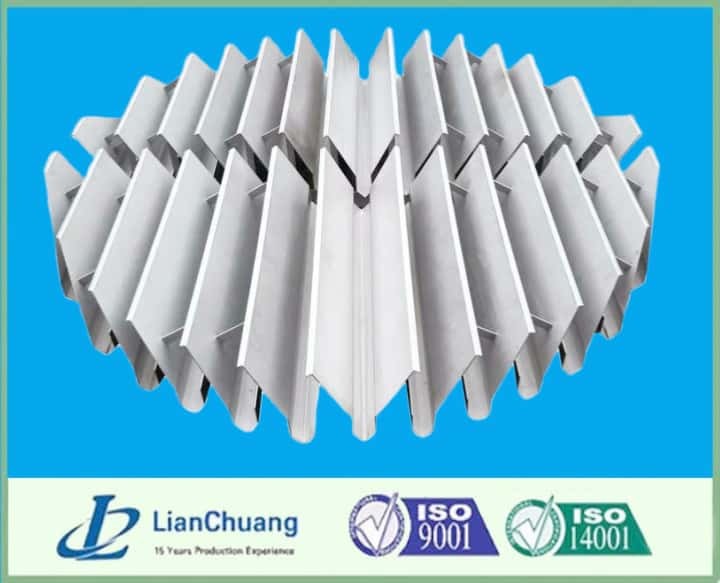

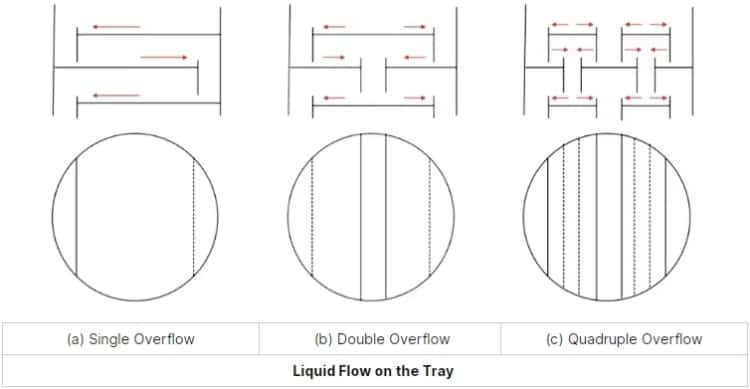

Overflow Patterns

Based on the feed rate and tower diameter, the tray can be configured for single, double, triple, or quadruple overflow, optimizing efficiency and capacity.

Applications

The Metal Bubble Cap Tray is ideal for various industries requiring efficient gas-liquid separation, including:

- Petrochemicals

- Refining

- Pharmaceuticals

- Fine chemicals

By combining robust construction with innovative design, the Metal Bubble Cap Tray delivers exceptional performance, making it a cornerstone of modern mass transfer technology.