Product Description

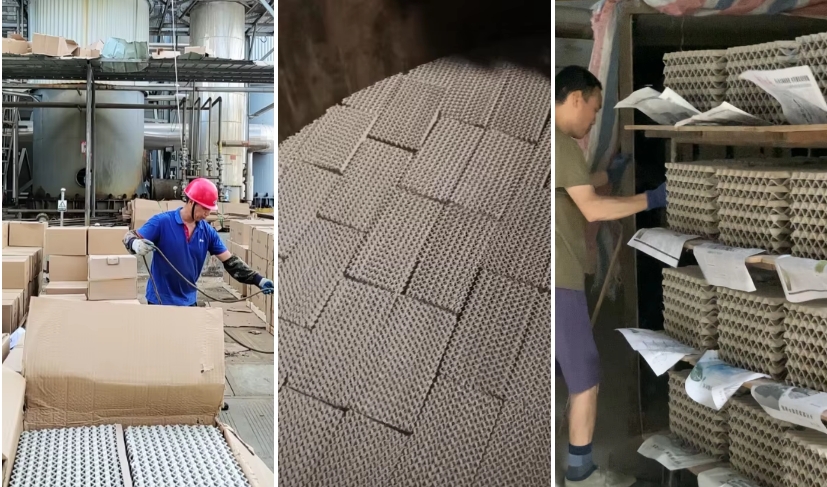

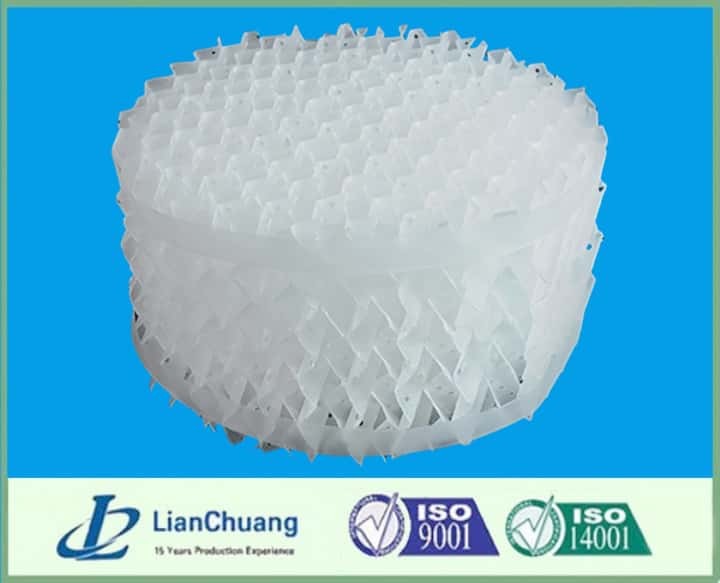

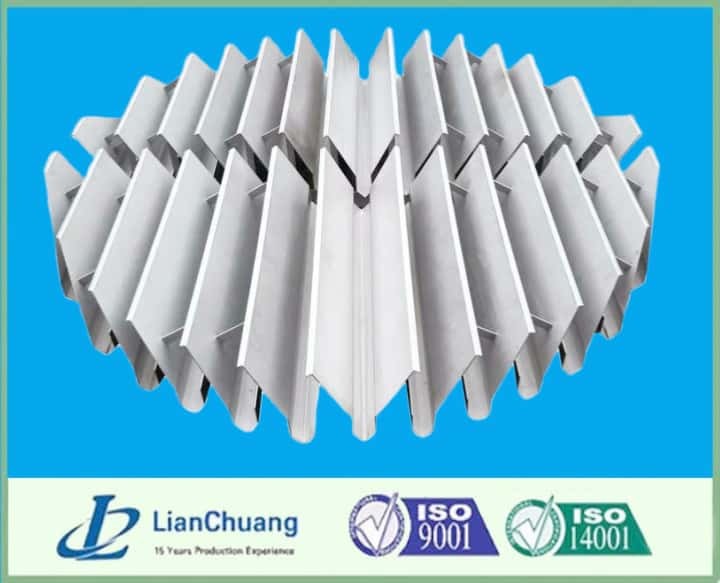

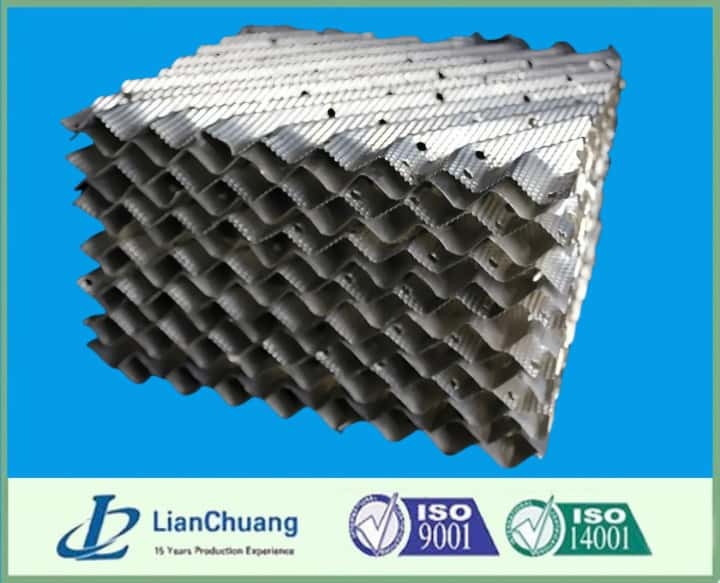

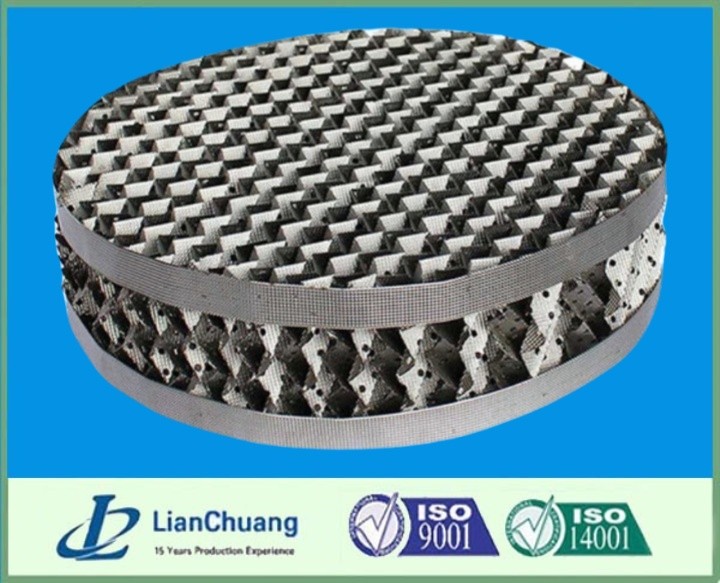

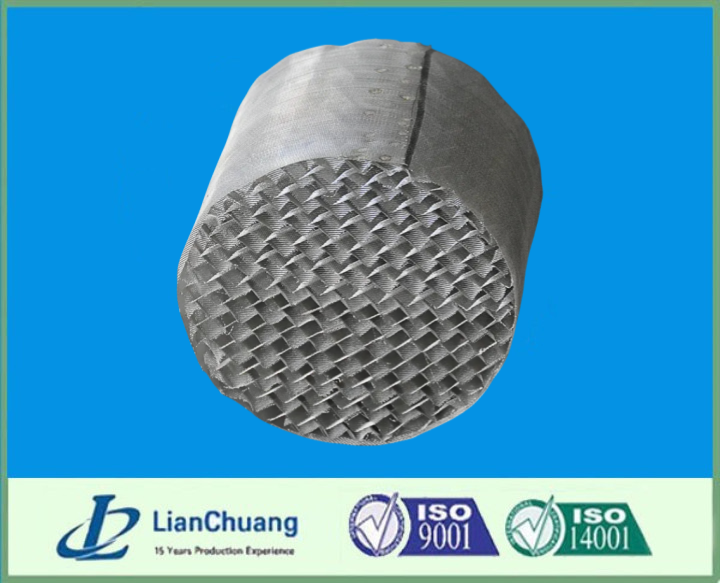

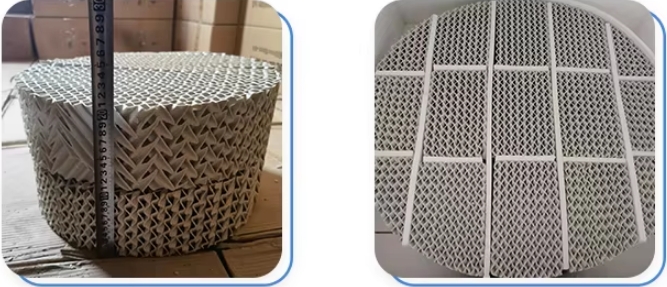

Ceramic structured packing also called ceramic corrugated packings are kind of column shape and single layer corrugated packing,consisting of many moire pieces with the same geometric shape and parallel to each other. Ceramic corrugated structured packings are divided into X-style and Y-style,and X and Y correspond to the 30℃ and 45℃ respectively.

Owing to ceramic structured packing's surface had good hydrophilic, it can enlarge to gas-liquid contacting surface area. Meanwhile,ceramic surface's microporous structure also improve wettability. In addition,ceramix excellent corrosion resistance makes Ceramic Corrugated plate more suitable for sulfuric acid absorption, the nitrate concentration. gas purification and so on.Ceremic high thermal stability make its operating temperature exceeds 1000 degree.

Advantages:

Chemical Resistance: Ceramic materials are highly resistant to corrosive substances, making them ideal for harsh chemical environments.

Thermal Stability: They can withstand high temperatures, which is beneficial for processes that operate at elevated temperatures.

Mechanical Strength: Ceramic packing can handle significant mechanical stress and pressure, reducing the risk of breakage or deformation.

Surface Area: The structured design provides a large surface area for mass transfer, enhancing efficiency in separation processes.

Low Pressure Drop: The design allows for good fluid flow with minimal pressure drop, improving overall system performance.

Performance Benefits:

Ceramic structured packing demonstrates superior performance compared to traditional random packing:

High Capacity: New towers can be designed with smaller diameters, while existing columns can achieve significant capacity increases during revamps.

Corrosion Resistance: It exhibits strong resistance to a wide range of mineral and organic acids, with partial resistance to alkalis.

Wide Turndown Ratio: This allows for easy scaling of operations.

Suitability for Various Column Sizes: Effective in columns of all diameters.

Corrugated Ceramic Structured Packings Specification:

Chemical composition | |||||

SiO2 | Fe2O3 | CaO | Al2O3 | MgO | Other |

≥72% | ≤0.5% | ≤1.0% | ≥23% | ≤1.0% | 2% |

Physical property | |||||

Index | Value | ||||

Specific gravity(g/cm3) | 2.5 | ||||

Water absorption(wt%) | ≤0.5 | ||||

Acid resistance(wt%) | ≥99.5 | ||||

Loss in burn(wt%) | ≤5.0 | ||||

Max. operating Temp.(Degree C) | 800 | ||||

Crush strength(Mpa) | ≥130 | ||||

Mohs Hardness(Scale) | ≥7 | ||||

cerramic structured packing applications:

(1) Rectifying organic halide.

(2) Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number.

(3) Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying theair in chemical plants.

(4) Operating in vacuum conditions at a bottom absolute pressure of 100pa.

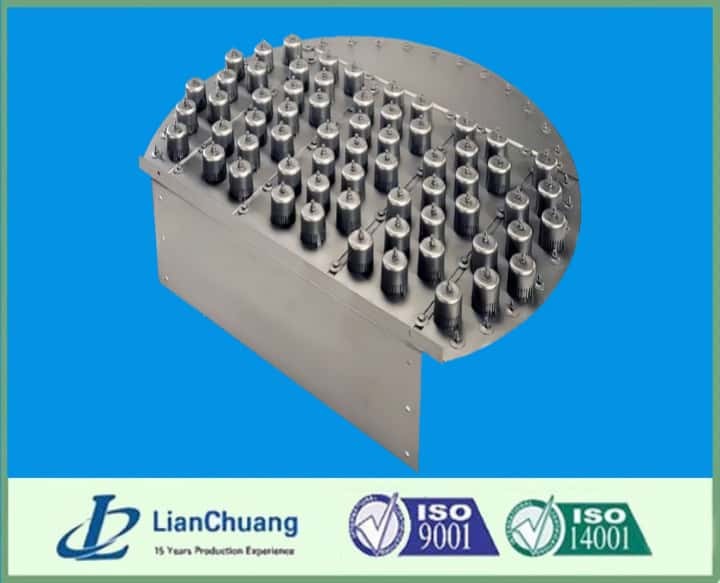

(5) Used in heat exchanger and demisting, or as a catalyst carry.

With its high separation efficiency, low pressure drop, and robust chemical resistance, ceramic structured packing is an ideal choice for various industrial applications. Its unique design not only improves operational efficiency but also enhances the performance of existing and new equipment.LianChuang makes the production of different specific surface area and flexible standard structured packing in terms of customer's demands.