Product Description

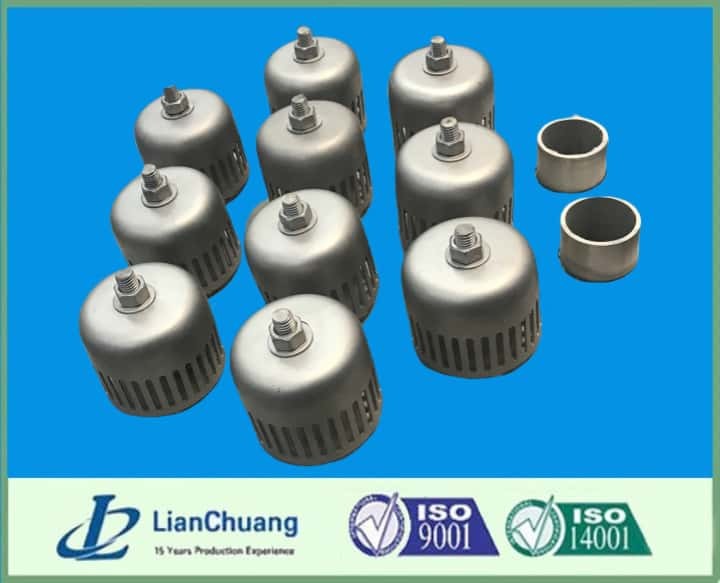

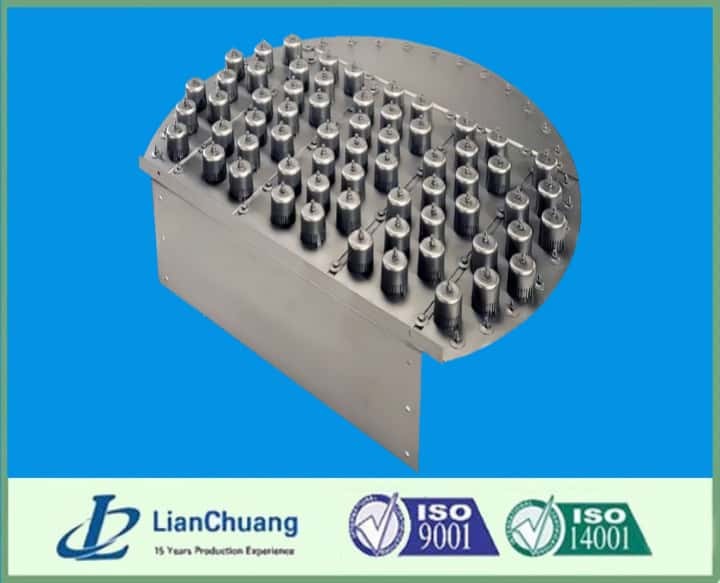

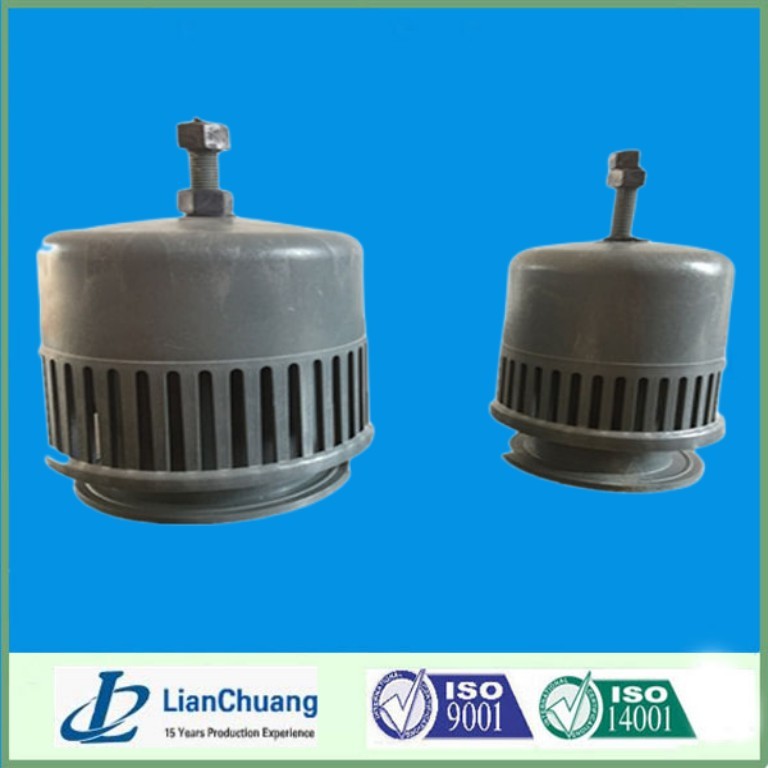

The Metal Bubble Cap is a structural component in a bubble-cap column, commonly used in applications requiring efficient liquid-vapor interaction, such as distillation and chemical reactions. The design of the bubble cap features a sleeved joint between the cap body and the gas-lift pipe, with bearing legs on the gas-lift pipe and bearing holes on the cap body. A backing pin with a positioning structure is used to secure the components without welding.

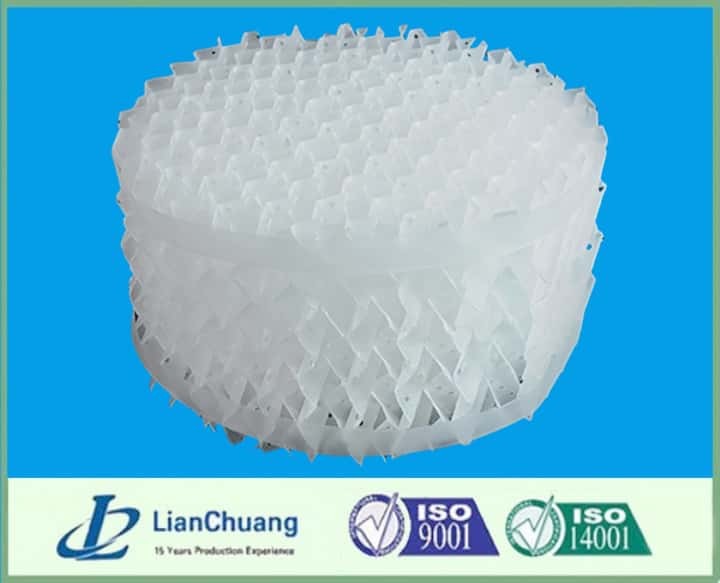

Bubble caps can be made from either metal or plastic materials, with Fluon being a particularly suitable option due to its excellent resistance to corrosion and long service life.

Design and Features of Metal bubble Cap:

Structural Integrity: The bubble cap’s design does not rely on the velocity of the vapor to hold the liquid on the tray, unlike some other designs. This makes it particularly useful for applications requiring a stable liquid seal across a range of flow rates.

Material Options: Bubble caps can be manufactured from corrosion-resistant materials, including stainless steel, aluminum alloy, and nickel alloy. Fluon (PTFE) bubble caps offer the added benefit of excellent resistance to corrosive environments and a long operational life.

No Welding Required: The assembly of the bubble cap is done without welding, providing ease of installation and flexibility for customization based on application requirements.

Temperature and Pressure Resistance: Bubble caps are designed to withstand high-temperature conditions (up to 1000°C, depending on the material), and are suitable for high-pressure applications, ensuring safe and stable operation in demanding environments.

Specifications:

Material: Stainless Steel, Aluminum Alloy

Sizes: Customizable to fit the dimensions of the column or tower

Shape: Available in common circular, square, or customized shapes

Temperature Range: Suitable for high-temperature environments (up to 1000°C depending on material)

Pressure Rating: Designed to handle high-pressure operations, ensuring stable and safe performance

Advantages:

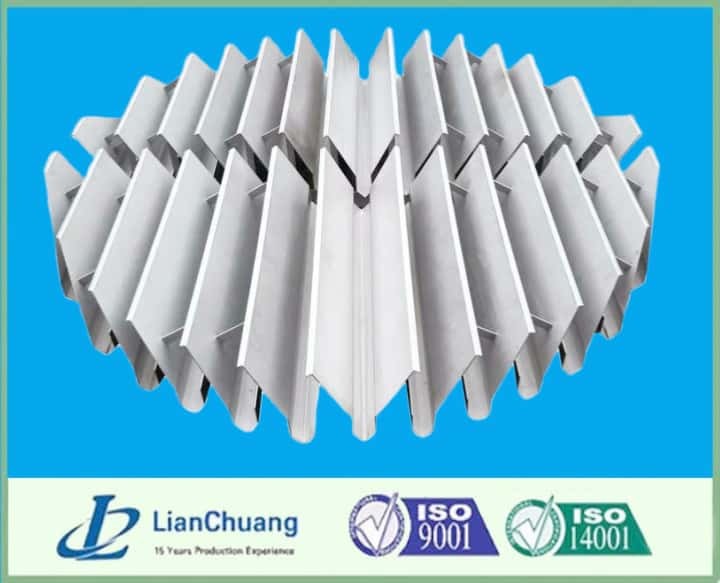

High Tray Efficiency: The bubble cap promotes full contact between the gas and liquid phases, resulting in a large mass transfer area. This leads to high tray efficiency, making it ideal for distillation and other separation processes.

Flexibility in Operation: The design allows for operation flexibility and can maintain high efficiency even under varying load conditions. It is well-suited for systems with fluctuating vapor rates.

High Production Capacity: Bubble caps are ideal for large-scale production, offering high production capacity and suitability for continuous operations in industrial applications.

Clogging Resistance: The bubble cap design minimizes the risk of clogging, allowing it to handle a wide range of mediums while ensuring stable and reliable operation.

Applications:

The Metal and Fluon Bubble Cap is primarily used in processes where efficient separation or chemical reaction is required, including:

Reactive Distillation: Used in processes requiring both reaction and separation, such as the production of certain organic products.

Separation of Organic Products: Effective in separating substances like benzene-methyl and nitrochlorobenzene.

Ethylene Oxidation and Absorption: Suitable for applications involving the oxidation and absorption of ethylene.

Enhance Your Distillation Process with Bubble Caps

With their high efficiency, flexibility, and resistance to corrosion, metal bubble caps provide an ideal solution for complex distillation and separation processes. Whether you're involved in reactive distillation or need to separate specific organic products, these bubble caps ensure reliable, long-lasting performance.