Product Description

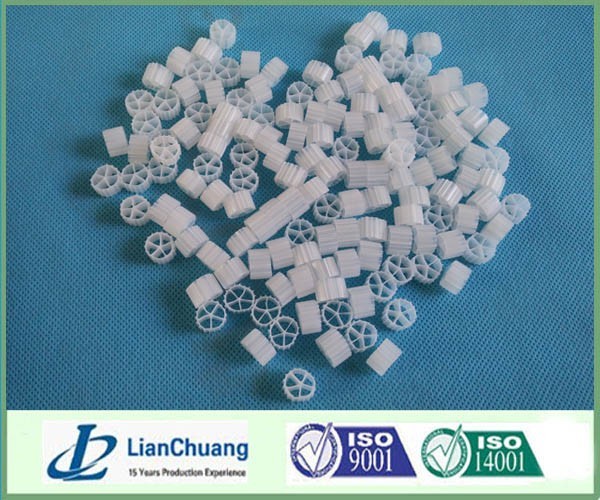

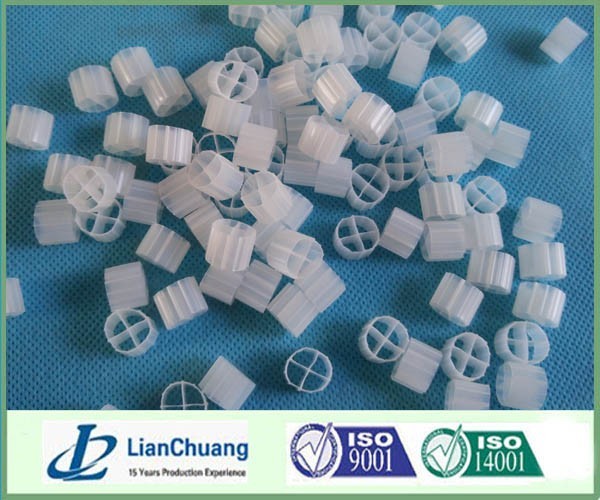

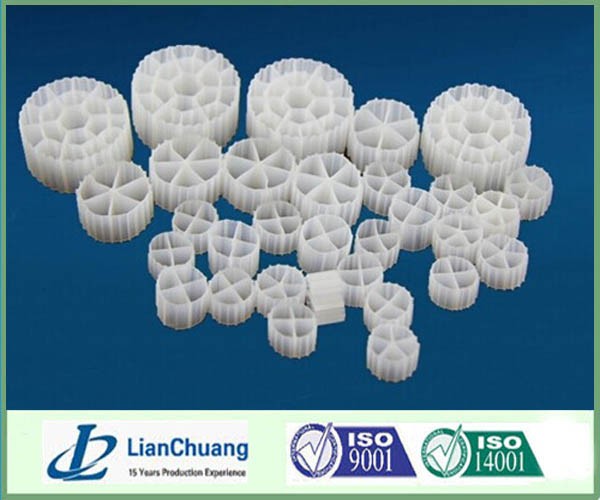

K1 MBBR Media, Kaldnes K1 Micro Moving Bed Biofilm Reactor Media Filter has a well-documented history of application in filtration systems. This polyethylene bio filter media is characterized by its unique wheel-like shape, featuring a cross-shaped central portion. Each piece measures 11 x 9 mm and provides a surface area exceeding 800 m²/m³. K1 Bio Media Plus is manufactured from virgin HDPE, which contributes to its high specific surface area, facilitating greater attachment opportunities for nitrifying bacteria. Its density is similar to water, allowing it to flow freely through aquatic environments.

K1 media can support not just bacteria but also other microorganisms. Like other mbbr media, k1 mbbr media is typically made of pure white polyethylene, which allows for easy visual monitoring of biofilm conditions. Designed specifically for use in fluidized bed filters, K1 kaldnes k1 Micro moving bed biofilm reactor media remains in constant motion as water flows through it, maximizing filtration efficiency. This movement enables the establishment of beneficial bacteria that play a crucial role in removing ammonia and nitrites from water, essential for maintaining a healthy environment for koi fish.

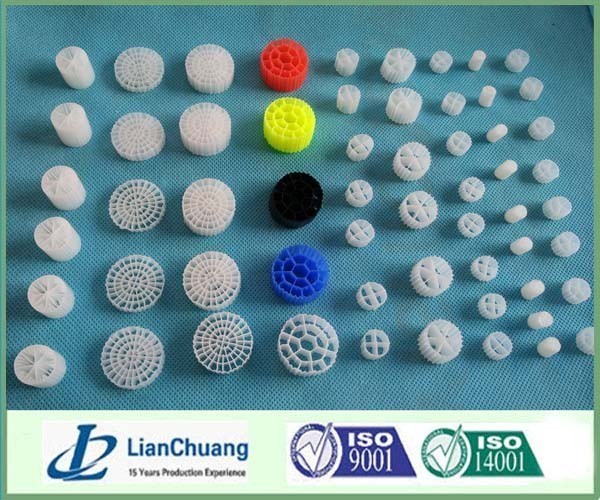

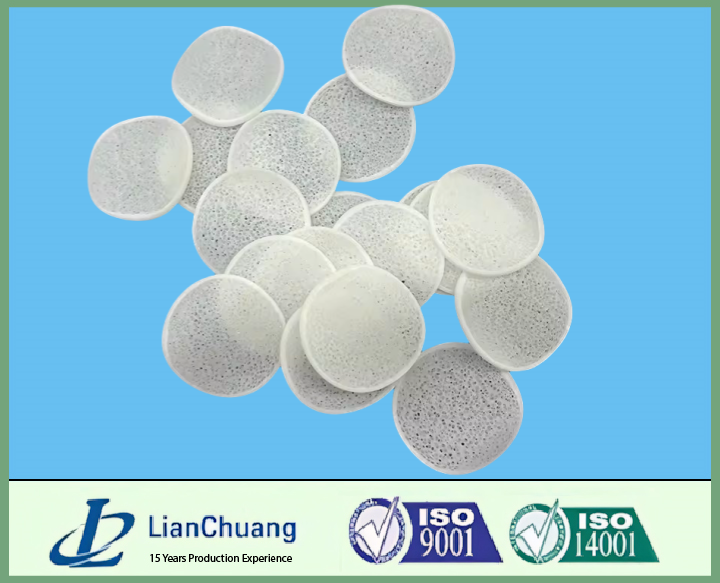

K1 MBBR filter media is versatile and suitable for various applications, including pond filters, aquaponics, hydroponics, sewage treatment, and more. It is slightly buoyant, making it ideal for both mechanical and biological filtration. Available sizes include 11 x 7 mm and 10 x 7 mm, with custom sizes available upon request. K1 MBBR media is widely used in aquaponics, aquaculture, hydroponics, ponds, aquariums, and the biological treatment of wastewater, as well as in newly constructed sewage treatment facilities utilizing MBBR and BAF processes.

MBBR Media Specifications:

Specification | Surface area | Packing numbers | Dosing ratio | Nitrification efficiency | Material |

(mm) | (m2/m3) | (Pcs/m3) | (%) | (Gnh4-N/m3.d) | |

Ф12×9 | >800 | >630000 | 15-17 | 400-1200 | HDPE |

Ф11×7 | >900 | >830000 | 15-68 | 400-1200 | HDPE |

Ф10×7 | >1000 | >850000 | 15-70 | 400-1200 | HDPE |

Ф16×10 | >800 | >260000 | 15-67 | 400-1200 | HDPE |

Ф25×12 | >500 | >97000 | 15-65 | 400-1200 | HDPE |

Ф25×4 | >1200 | >210000 | 15-65 | 500-1400 | HDPE |

Advantages:

1. High volume load and compact land use make K1 Moving-Bed Biofilm Reactor (MBBR) particularly effective for upgrading existing sewage treatment plants. Without requiring additional land, simple modifications can increase sewage treatment capacity by 2-3 times and improve effluent quality. The moving bed biofilm process occupies only 20-30% of the space.

2. The system demonstrates strong impact resistance, stable performance, and reliable operation. The moving bed process is less affected by changes in impact load and temperature compared to traditional activated sludge processes. Even when the composition of sewage changes or its toxicity increases, the biofilm remains resilient.

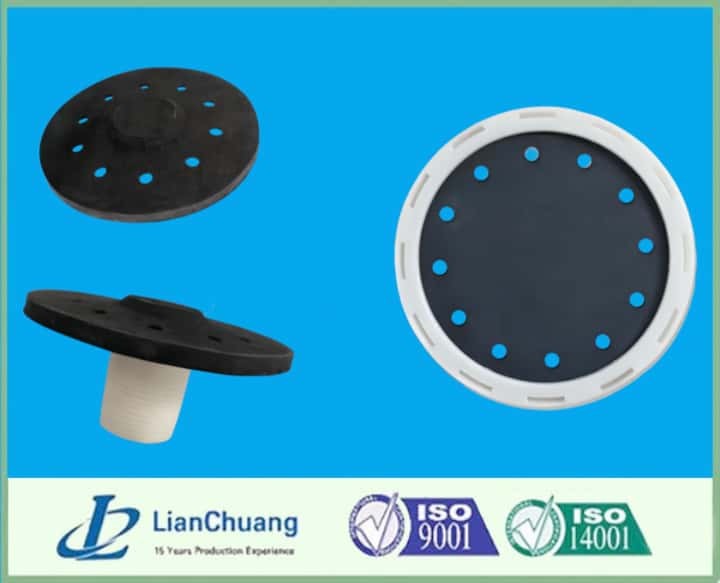

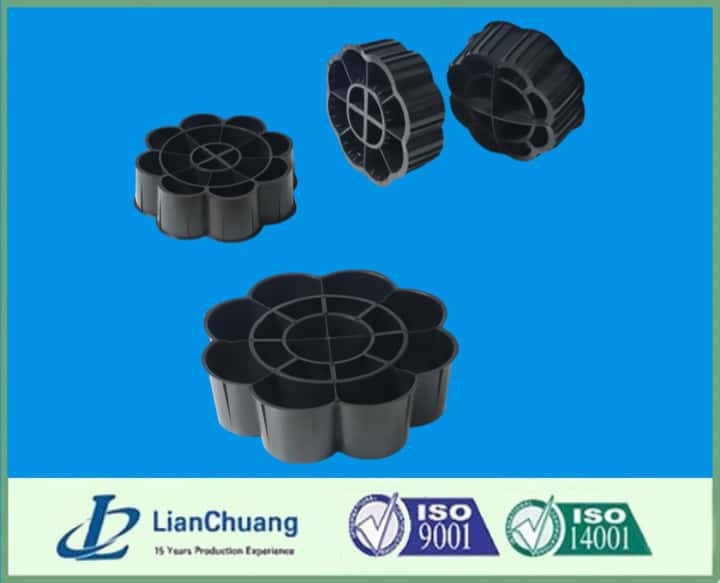

3.The mixing and aeration system is user-friendly and easy to maintain. It utilizes a perforated aeration pipe system that minimizes blockage. The agitator features a banana-type blade, designed to gently mix without damaging the packing, ensuring easy maintenance.

4.The biological pool is free from blockages, allowing for complete utilization of its volume with no dead zones. The design ensures that the packing and water flow are thoroughly mixed throughout the pool, fundamentally eliminating the potential for blockages.

5. The system is flexible and convenient. It can accommodate various pool types (deep, shallow, square, or circular) without compromising treatment effectiveness. Additionally, different filler filling rates can be easily adjusted to enhance efficiency and support long-term expansion without increasing tank capacity. For upgrading existing activated sludge treatment plants, the fluidized bed biofilm process can seamlessly integrate with existing systems.

6. The high-quality, durable biological packing, aeration system, and effluent devices ensure the system's long service life, minimizing the need for replacements and maintaining a low depreciation rate.

Packages:

Container | 1*20GP | 1*40GP | 1*40HQ |

Packed Q"ty | 28m3 | 59m3 | 68m3 |

Notes:

1. We can disign different packing according to your requirements.

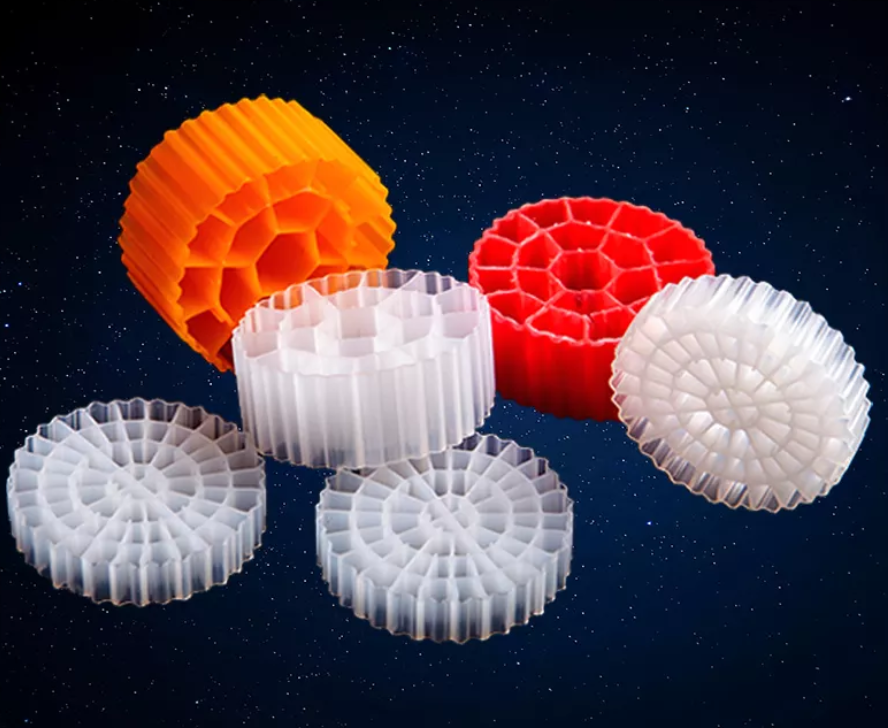

2. Our factory can produce all kinds of mbbr media with different size or color.

3. All of our mbbr filter media made from virgin polyethylene, not recycled material that might be toxic!