Product Description

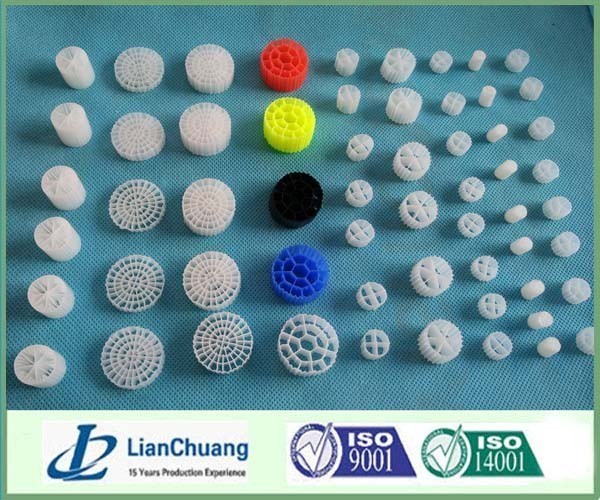

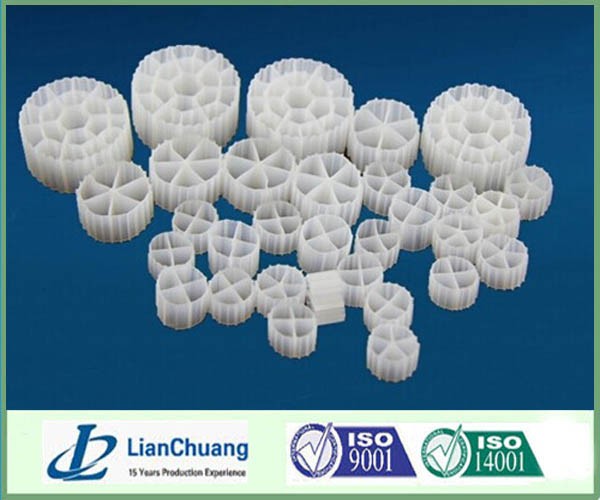

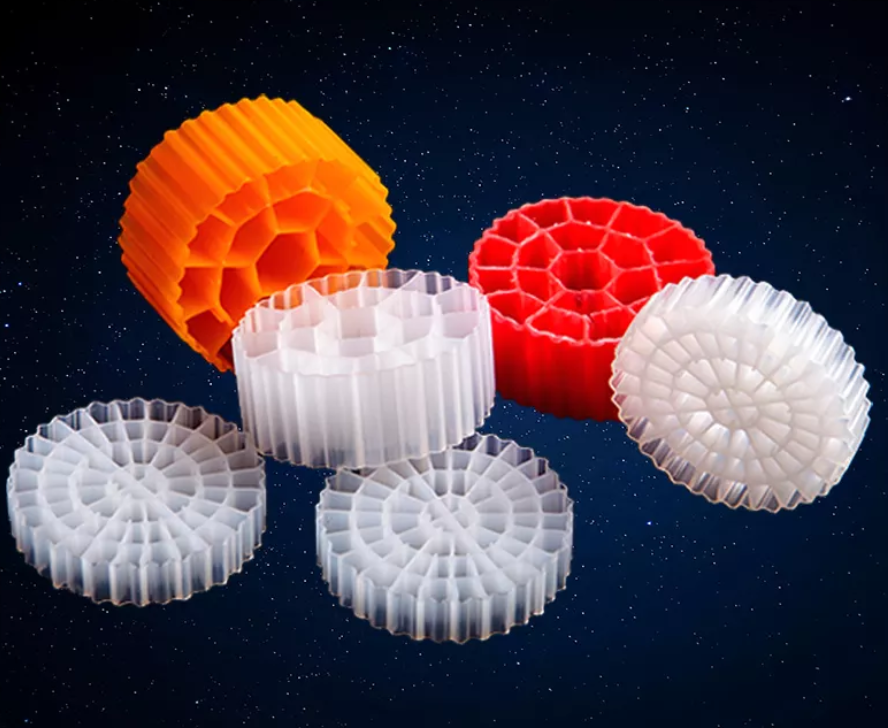

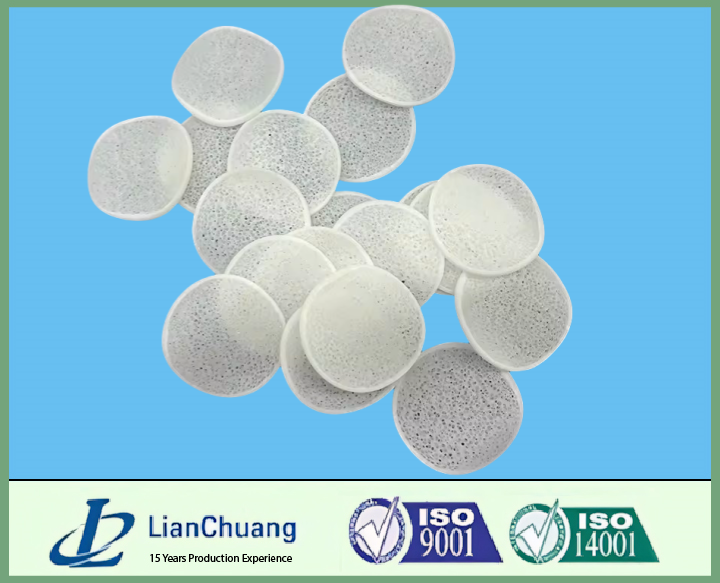

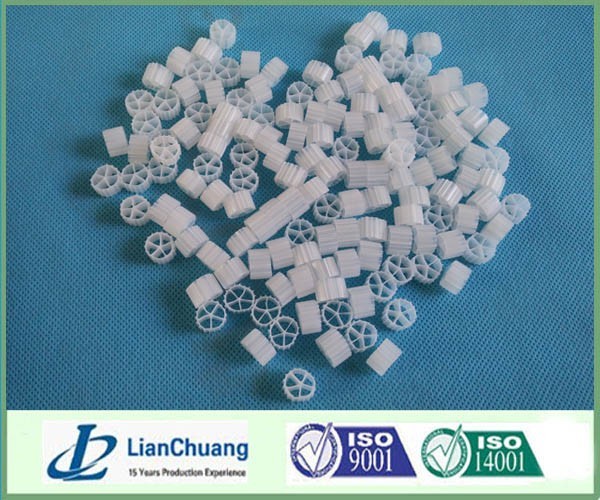

Moving bed filter is is a new kind of suspension biofilm media carrier media, moving bed filter media used in moving bed biofilm reactor system and integrated fixed-lm activated sludge (IFAS). A moving bed filter is an innovative type of suspension biofilm media carrier, commonly used in Moving Bed Biofilm Reactor (MBBR) systems and Integrated Fixed-Film Activated Sludge (IFAS) processes. In an MBBR system, wastewater passes through suspended biofilm media, gradually forming a biological membrane on the media surface. The microbes present on the biofilm then purify the wastewater. The moving bed filter media are able to move freely within the reactor due to the water mixing, enhancing the biological treatment process.

The moving bed filter media are versatile and can be used in both aerobic and anaerobic processes. In aerobic reactors, aeration causes the media to move, while in anaerobic reactors, mechanical mixing facilitates the movement. Compared to traditional media, MBBR biofilm media offer superior treatment efficiency. The MBBR system is a cost-effective solution for upgrading existing activated sludge plants that require advanced treatment without needing to significantly expand infrastructure. Due to its compact nature, it is ideal for plants with limited space for expansion and can also be an excellent choice for space-efficient, high-performance designs in new plants.

MBBR (Moving Bed Biofilm Reactor) System Overview:

- Filtration Mechanism: MBBR systems do not have a built-in solids removal mechanism, so solids must be separated using a clarifier. The plastic media, with a moderate surface area, supports biofilm growth that breaks down dissolved organic matter in wastewater.

- Treatment Efficiency: MBBR systems are highly effective in removing dissolved organic pollutants and ammonia.

- Biological Treatment: MBBR is a fixed-film bioreactor. In an aerated configuration, it is used for organic matter oxidation or nitrification. When combined with mechanical mixing, MBBR can also facilitate denitrification.

System Design Considerations:

- Footprint: MBBR systems are compact, requiring similar space to floating bead filters for equivalent treatment capacities. However, they usually necessitate additional solids removal processes (such as pre- and post-clarification), which may increase the overall footprint.

- Maintenance: MBBR systems are low-maintenance, with occasional inspections needed for outlet screens in certain cases. Regular maintenance of blowers is required, and while most reactors lack internal moving parts, periodic cleaning of injectors may be necessary. Some bio-carrier designs may require media replacement every decade.

Characteristics of Moving Bed Filter Media:

- Increased treatment capacity

- Enhanced removal of BOD (Biochemical Oxygen Demand) and nitrogen

- Quick recovery from process upsets

- Compact footprint

- Potential for future expansion

- Simplified process complexity and reduced operator attention

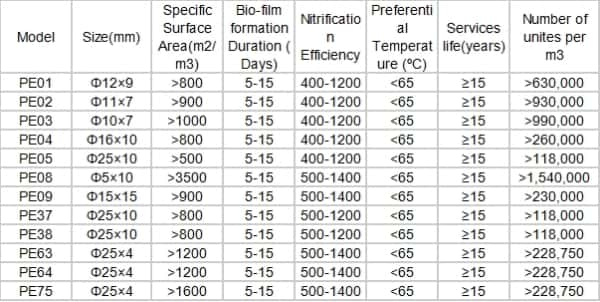

Specifications of Moving Bed Filter Media:

Applications of Biofilm Media:

- Upgrading sewage treatment plants

- New sewage treatment projects utilizing MBBR and BAF processes

- Biochemical treatment of reclaimed water

- Nitrogen and phosphorus removal in rivers

- Ammonia nitrogen removal and water purification in aquaculture

- Biological deodorization towers

Note: We offer OEM and ODM services for customized solutions tailored to your specific requirements. Contact us today, and we will respond to your inquiry within 24 hours.