Product Description

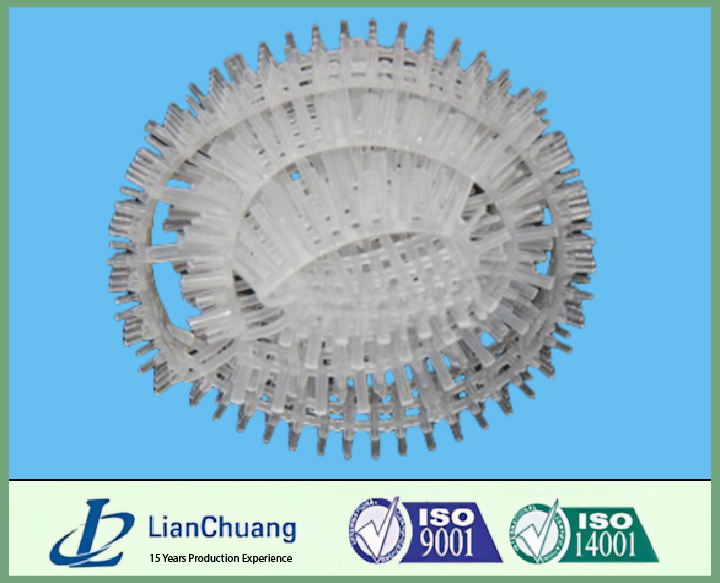

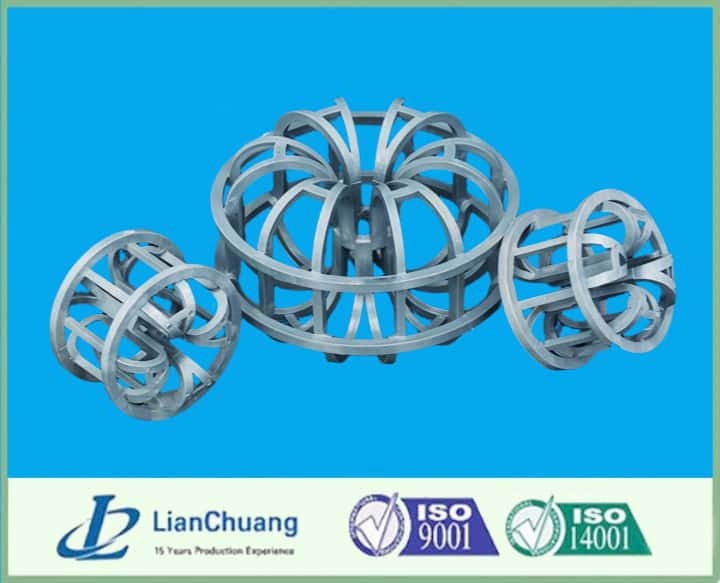

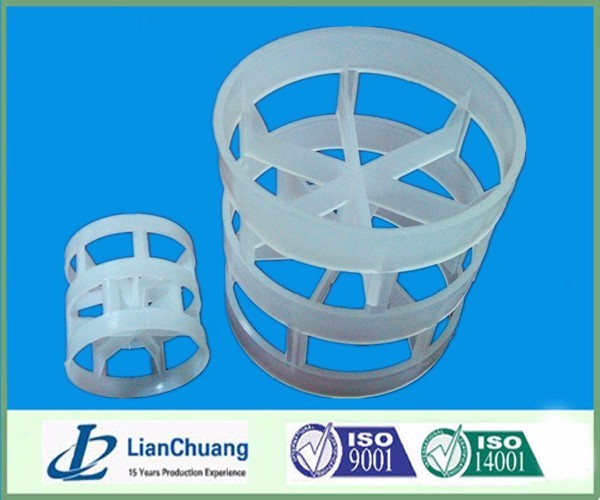

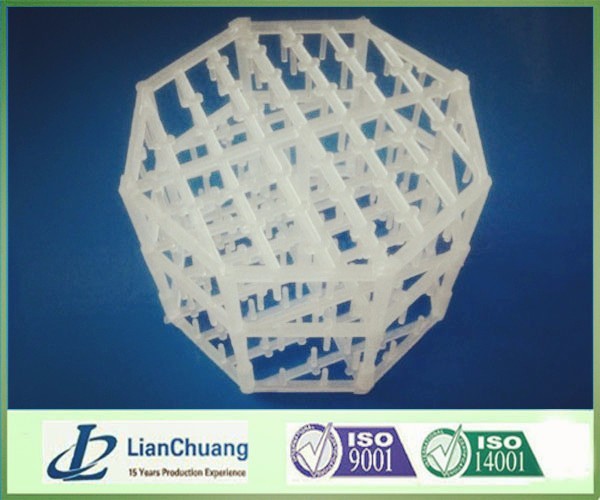

nupac tower packing distinguishes itself through its markedly greater surface area per cubic foot relative to other similar-sized random packings. This distinctive attribute renders it exceptionally suited for rigorous mass and heat transfer requirements, guaranteeing an engineered surface of utmost quality to achieve peak efficiency. Moreover, nupac tower packing fosters luxuriant and uniform biological growth on its plastic media, establishing it as the favored option for biological applications.

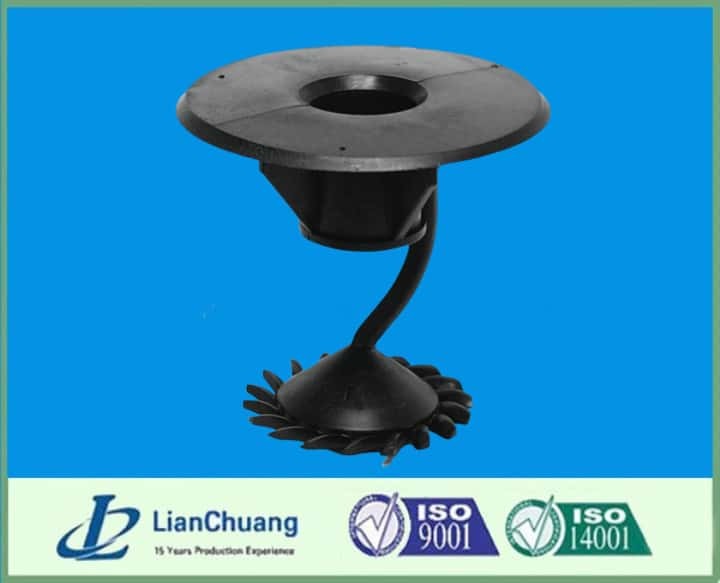

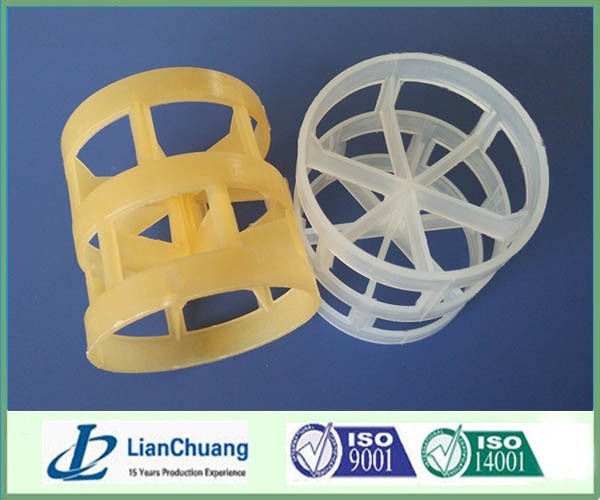

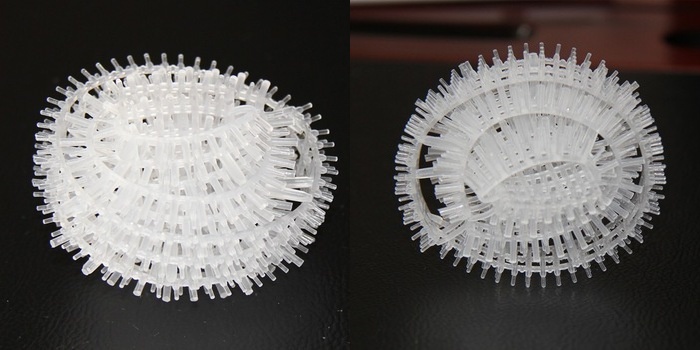

NUPAC Tower Packing suit advanced engineering for Industrial Applications Unrivaled Efficiency with Minimal Pressure Drop Introducing NUPAC® Tower Packing, a pinnacle of engineering designed to innovate your industrial processes. Whether you're enhancing scrubbers, strippers, bio reactors, or mist eliminators, nupac delivers unmatched performance with a focus on reducing pressure drop. Nupac tower packing fosters uniform and robust biological growth on its plastic media, making it the preferred choice for biological applications. Product Options and Specifications.

NUPAC Tower Packing suit advanced engineering for Industrial Applications Unrivaled Efficiency with Minimal Pressure Drop Introducing NUPAC® Tower Packing, a pinnacle of engineering designed to innovate your industrial processes. Whether you're enhancing scrubbers, strippers, bio reactors, or mist eliminators, nupac delivers unmatched performance with a focus on reducing pressure drop. Nupac tower packing fosters uniform and robust biological growth on its plastic media, making it the preferred choice for biological applications. Product Options and Specifications.

Advantage of Nupac Tower Packing:

1. High Specific Surface Area and Enhanced Mass Transfer Efficiency:The polypropylene dehydration packing boasts an exceptionally high specific surface area, ensuring efficient mass transfer.

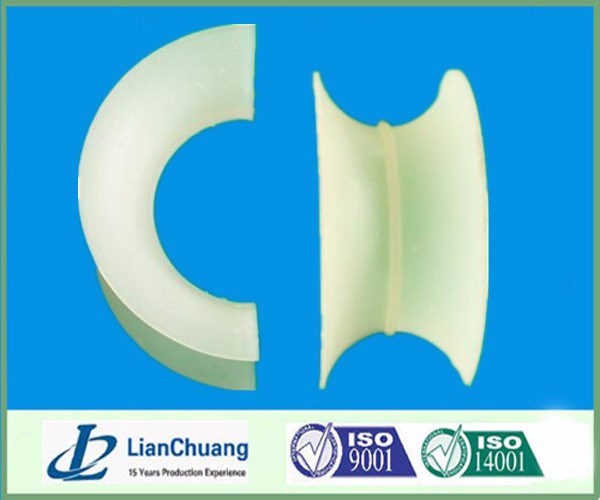

2. Unique Needle Column and Spherical Ball Geometric Design:This design facilitates the generation of small bubbles, optimizing aeration oxidation efficiency. It is especially suitable for projects dealing with organic wastewater, enhancing treatment and transformation processes without requiring extensive land use.

3.Enhances Efficiency and Capacity in Retrofitting Existing Stripping Towers:By incorporating polypropylene dehydration packing, efficiency and processing capacity in revamped stripping towers can be significantly improved.

4. Effective Mist Removal Layer:When utilized as a mist removal medium, polypropylene NUPAC packing achieves a removal rate of 99% for liquid droplets larger than 10 microns, with an optimal installation height ranging from 460 to 610mm.

5. Biofilm Support in Biological Treatment Systems: Polypropylene NUPAC packing serves effectively as a biofilm support medium in biological treatment systems, promoting robust biological activity.

6. High Specific Surface Area and Enhanced Mass Transfer Efficiency:The polypropylene dehydration packing boasts an exceptionally high specific surface area, ensuring efficient mass transfer.

7. Unique Needle Column and Spherical Ball Geometric Design:This design facilitates the generation of small bubbles, optimizing aeration oxidation efficiency. It is especially suitable for projects dealing with organic wastewater, enhancing treatment and transformation processes without requiring extensive land use.

8. Enhances Efficiency and Capacity in Retrofitting Existing Stripping Towers:By incorporating polypropylene dehydration packing, efficiency and processing capacity in revamped stripping towers can be significantly improved.

9. Effective Mist Removal Layer:When utilized as a mist removal medium, polypropylene NUPAC packing achieves a removal rate of 99% for liquid droplets larger than 10 microns, with an optimal installation height ranging from 460 to 610mm.

10. Biofilm Support in Biological Treatment Systems:Polypropylene NUPAC packing serves effectively as a biofilm support medium in biological treatment systems, promoting robust biological activity.

Specification of Nupac Packing:

SPECIFICATION | #2 NUPAC; | #4 NUPAC |

Nominal Size | 2.5 inches | 4.5 inches |

Void Fraction | 90.90% | 94.20% |

- Polypropylene | 5.1 lb/ft³ | 3.1 lb/ft³ |

- PVDF | 9.0 lb/ft³ | 6.3 lb/ft³ |

- Glass-Filled PP | 5.5 lb/ft³ | 3.9 lb/ft³ |

Surface Area | 55 ft²/ft³ | 40 ft²/ft³ |

Number of Pieces | 125 pieces/ft³ | 22 pieces/ft³ |

Packing Factor | 16 | 8 |

Mataterial Choice:

| Performace/Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density(g/cm3)(after injection molding) | 0.98 | 0.96 | 1.2 | 1.7 | 1.8 | 1.8 |

| Operation temp.(℃) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | GOOD | GOOD | GOOD | GOOD | GOOD | GOOD |

| Compression strength(Mpa) | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 | >6.0 |