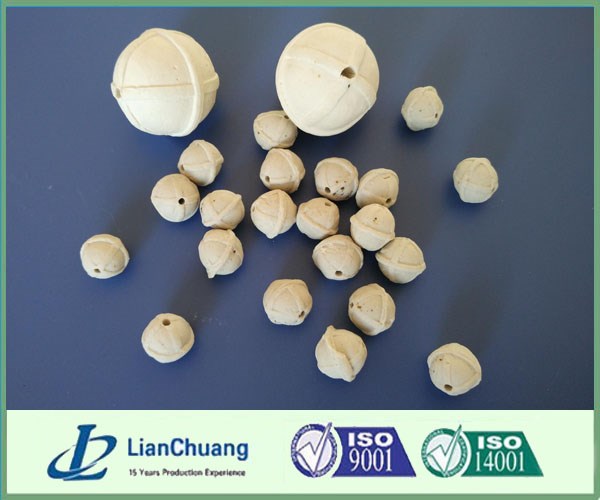

Product Description

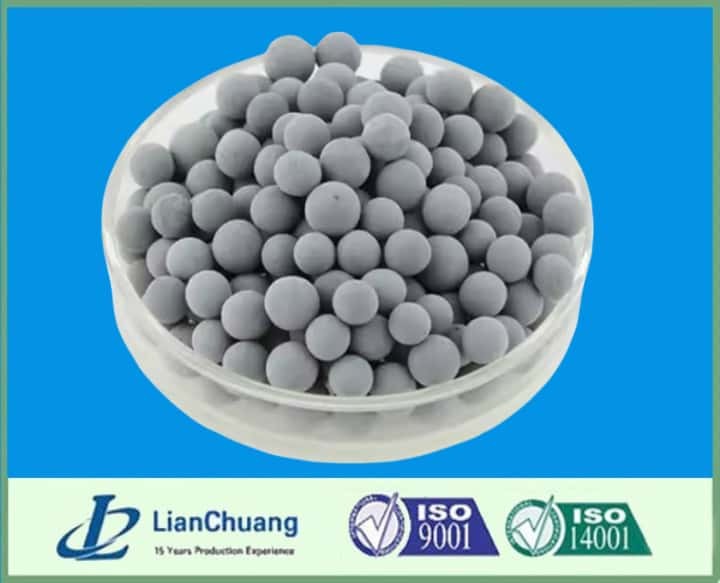

Perforated ceramic balls ( also named the filtrating ceramic ball ) are perforated based on the spherical diameter of the inert ceramic ball as the axis; convex-concave groove perforated ball is opened groove and presented convex-concave body on the surface of the perforated ball. Compared with ordinary inert ceramic balls, perforated ceramic balls have better vapor-liquid dispersion effect, larger porosity and specific surface area. resistance decreased by 15%, contact surface area increased by 25%, porosity increased by 12%.

So perforated ceramic balls not only has inert ceramic ball function, but also can can be utilized to the impurities filtrating in the oil for absorbing impurity for protecting the catalyst.As the particle sizes of the impurities in the raw materials are different among the hydrogen producing,different size Porus Ceramic Ball was made according to the real requirement. This product has highly acid, alkali - resistant, heat resistant than tables, high porosity, reduced resistance to a more uniform distribution of gas-liquid flow increased, and not compacted catalyst, not charred, extended catalyst life. As the impurities present in the materials are different, the user can select the product by their sizes, pores and porosity, or if necessary, add molybdenum, nickel and cobalt or other active components to prevent the catalyst from coking or poisoning.

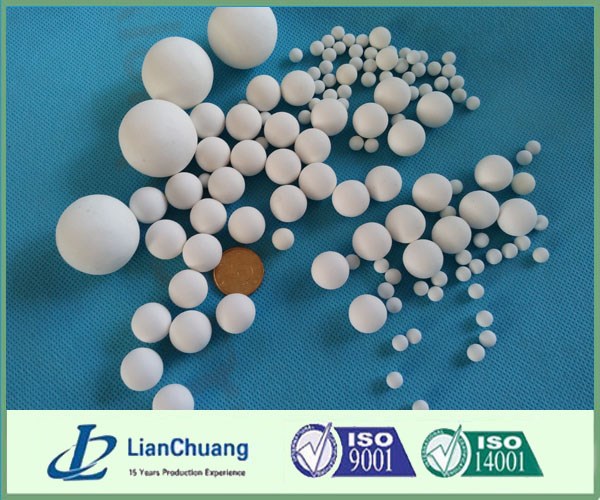

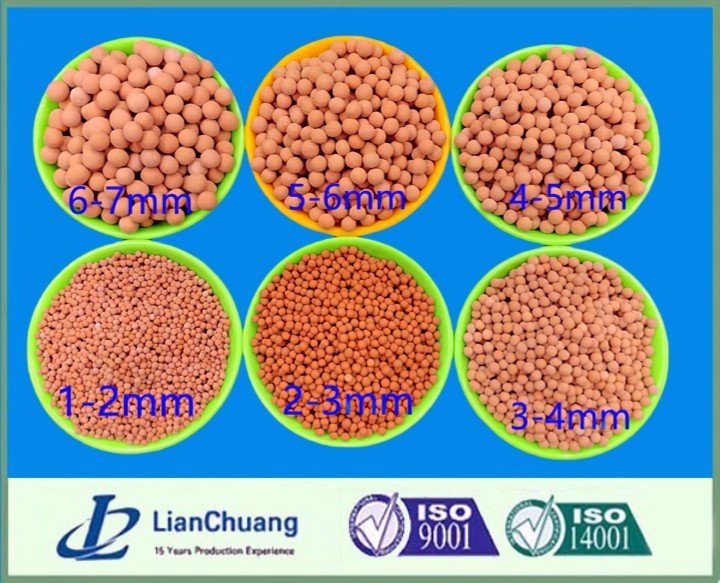

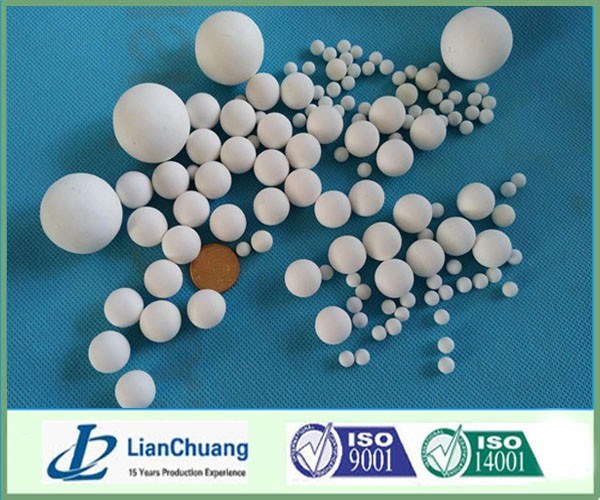

Perforated ceramic balls Size:

Perforated ceramic balls are divided into 12 grades by reference to Al2O3 content varied from 25% to 80%,and every more 5% constitutes a grade, but 12 sizes by reference to the diameter, such as Φ3mm,Φ6mm,Φ8mm,Φ10mm,Φ13mm,Φ16mm,Φ20mm,Φ25mm,Φ30mm,Φ40 mm,Φ50mm,Φ60mm. The products in other grade and sizes can be designed and manufactured if to the users request.

Tolerance:

Diameter | Φ6 | Φ8 | Φ10 | Φ13 | Φ16 | Φ20 | Φ25 | Φ30 | Φ38 | Φ50 | Φ60 | Φ75 |

Tolerance (mm) | ±1.0 | ±1.5 | ±2.0 | ±3.0 | ||||||||

Perforated aperture (mm) | 2-3 | 3-5 | 5-8 | 8-10 | ||||||||

Product Parameter for Perforated ceramic balls:

Index | Unit | Data | |

Al2O3+SiO2 | % | >90 | |

Al2O3 | % | 16-30 | |

SiO2 | % | 68-73 | |

Fe2O3 | % | <1 | |

Application of perforated ceramic balls Size:c

Perforated ceramic balls have a broad range of applications, particularly in industries where filtration, catalytic processes, and chemical reactions are involved. Some of the key uses include:

1. Catalysis and Chemical Processing

Perforated ceramic balls are often used as carriers or supports for catalysts in chemical reactors. The increased surface area provided by the perforations allows for more efficient chemical reactions. In catalytic processes, these balls help in optimizing the interaction between gases or liquids and the catalyst, increasing the overall reaction rate and improving process efficiency.

2. Wastewater Treatment

In wastewater treatment plants, perforated ceramic balls are used in biofilters to support the growth of microorganisms that break down organic contaminants. The porous structure allows for a high level of oxygen exchange and nutrient absorption, supporting the biological treatment process. These balls are particularly useful in biological filtration systems where efficient waste removal is crucial.

3. Gas Absorption and Scrubbing Systems

Perforated ceramic balls are utilized in gas absorption and scrubbing systems, where gases are passed through a liquid to remove contaminants. The increased surface area from the perforations helps to maximize the interaction between the gas and the liquid, improving the efficiency of the absorption process.

4. Air Purification and Filtration

In air filtration systems, perforated ceramic balls are used as a support medium for filters. Their porous structure enables efficient airflow while capturing dust, smoke, and other airborne particles. The ceramic material’s resistance to heat and chemicals ensures the longevity and effectiveness of the filtration process.

5. Heat Storage and Transfer

The high thermal stability of perforated ceramic balls makes them ideal for use in heat storage and heat transfer applications. In systems such as thermal energy storage (TES), these balls are used to store and transfer heat efficiently, ensuring consistent and reliable energy performance.