Product Description

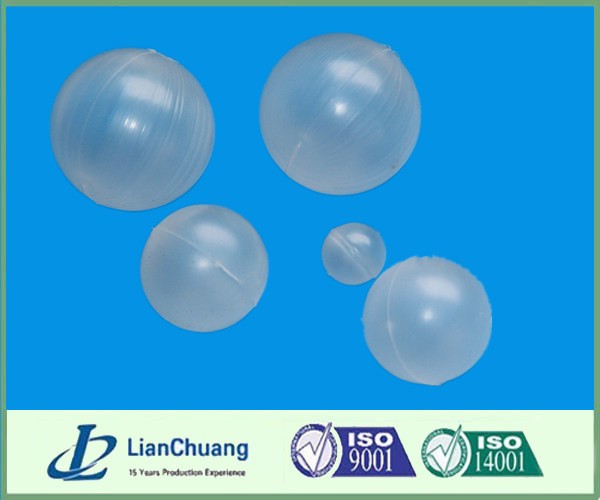

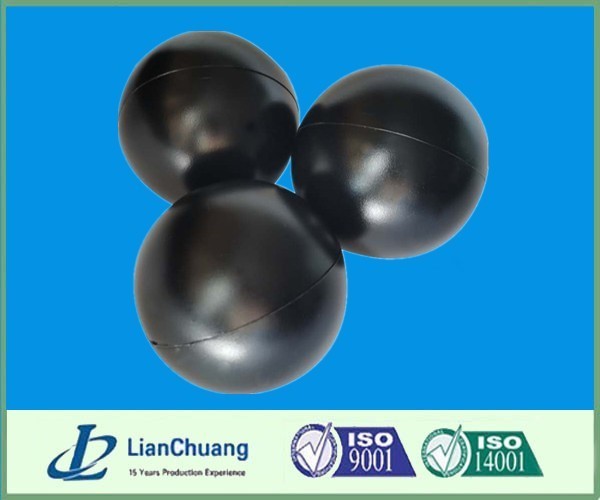

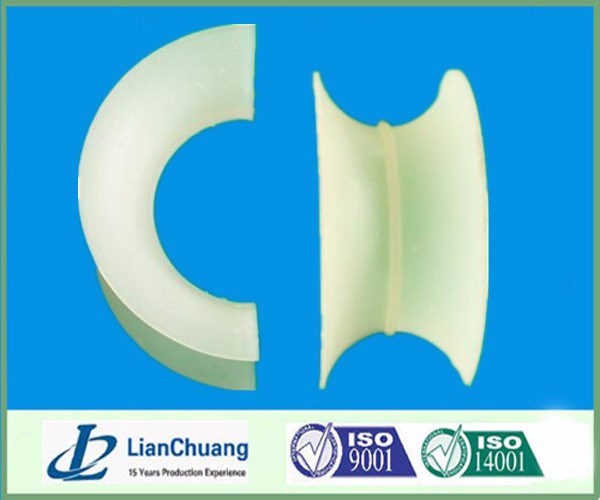

The Plastic Hollow Floating Ball is an essential component in various industrial processes, known for its reliable performance in gas, petroleum, chlor-alkali, chemical, and metallurgy fields. Its robust design and versatile applications make it a preferred choice for professionals seeking efficient and sustainable solutions.

These features make it widely used in the petroleum, chemical, alkali chloride, gas, and environmental protection industries, with a maximum operating temperature of 150°C. The Plastic Hollow Floating Ball can be manufactured from various materials, including PE, PP, PVC, PVDF, and CPVC, to meet different application needs.

Key Features of Plastic Float Balls

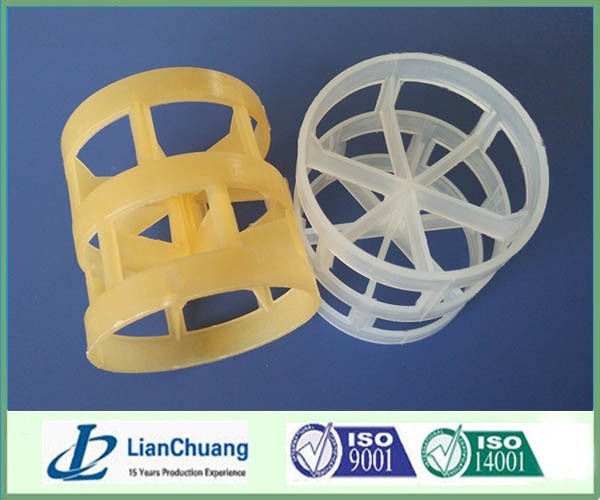

- High Free Volume: Ensures efficient packing and operational performance.

- Low Pressure Drop: Minimizes energy consumption.

- Low Mass-Transfer Unit Height: Enhances mass transfer efficiency.

- High Flooding Point: Improves operational stability.

- Uniform Gas-Liquid Contact: Maximizes contact efficiency.

- Small Specific Gravity: Reduces the overall weight of the packing.

- High Mass Transfer Efficiency: Ensures optimal performance in various applications.

Temperature and size Range

- Suitable for media temperatures ranging from 60°C to 150°C.

- size:6mm, 10mm, 13mm, 15mm, 20mm, 30mm, 38mm, 50mm, 76mm, 100mm

Advantages

The Plastic Hollow Floating Ball is also known as plastic hollow flotation ball packing and offers numerous benefits:

- High Void Ratio: Enhances filtration capacity and efficiency.

- Good Chemical Corrosion Resistance: Ensures durability and long service life.

- Minimizes Acid Mist and Heat Loss: Provides effective environmental protection.

- Particle Control: Suitable for controlling particles in various applications.

Performance Characteristics

- Stable Center of Gravity: Maintains balance and operational stability.

- Low Mass Transfer Unit Height: Ensures efficient mass transfer.

- Good Coverage Effect: Provides excellent coverage and protection.

- Water Quality and Energy Conservation: Enhances environmental purification efforts.

Applications

Due to its exceptional properties, the Plastic Hollow Floating Ball is widely used in various industries, including:

- Petroleum Industry: Packing towers, condensate tanks.

- Chemical Industry: Scrubber towers, cooling towers.

- Alkali-Chloride Industry: Acid storage tanks, demineralized water tanks.

- Coal Gas Industry: Waste gas recovery, exhaust gas purification.

- Environmental Protection: Mist and odor control, acid mist purification.

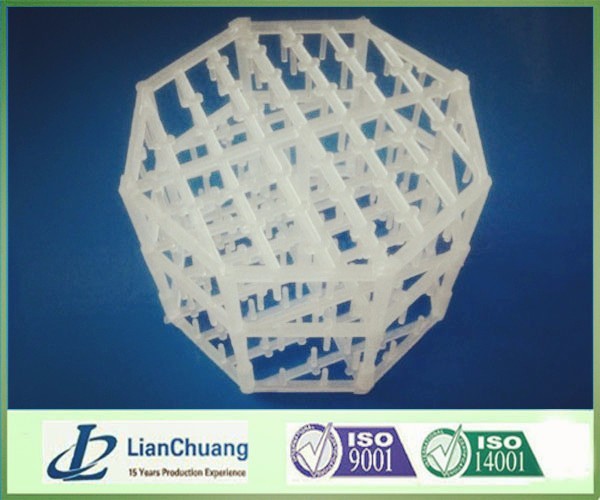

PP (Polyhedral) Hollow Ball Specifications:

Size | Average Weight | Number | Number |

(mm) | (g) | (n/ft2) | (n/m2) |

10 | 0.2 | 1076 | 11600 |

20 | 1 | 270 | 2900 |

25 | 1.5 | 172 | 1850 |

38 | 4.5 | 74 | 800 |

45 | 7 | 53 | 570 |

50 | 8 | 43 | 465 |

55 | 10.5 | 35 | 380 |

70 | 16 | 22 | 235 |

100 | 40 | 10 | 116 |

150 | 100 | 5 | 55 |

(Polypropylene material just for reference)

Note:

Material of could be PE,PP, HDPE, PVDF etc.