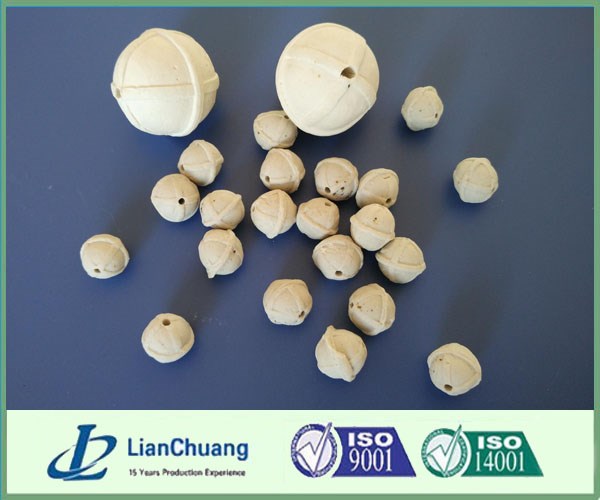

Product Description

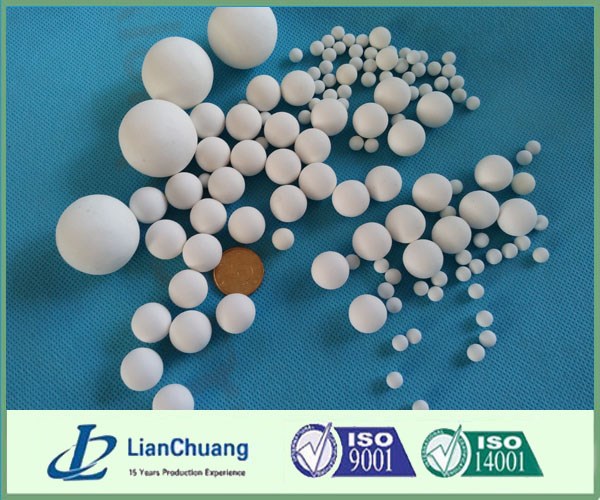

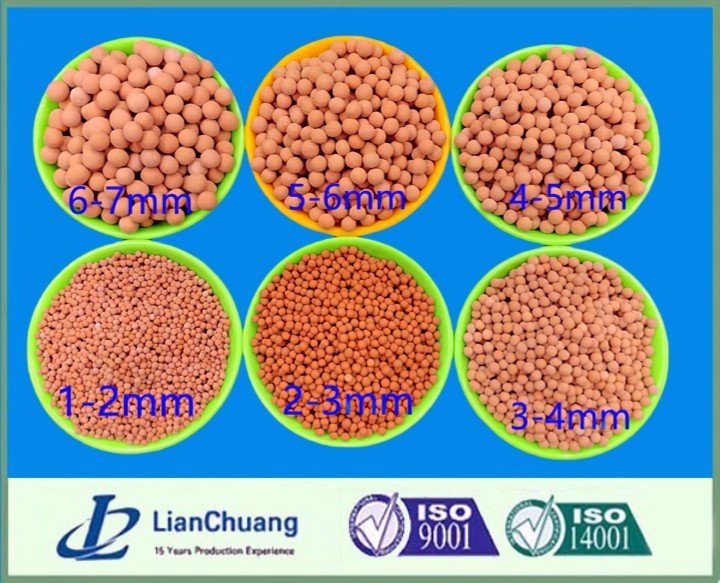

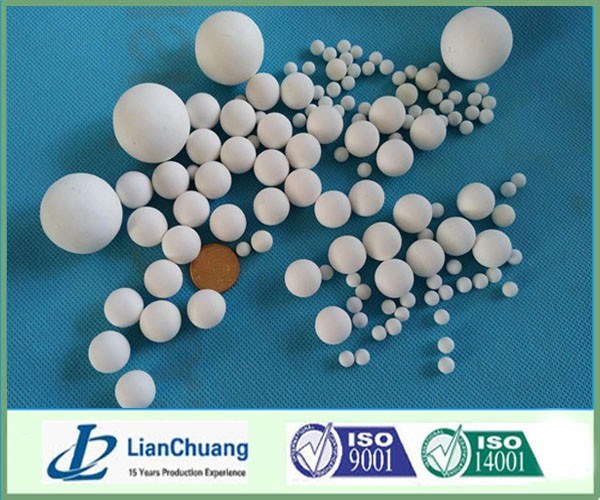

Refractory Ceramic Balls are produced by using industrial alumina and fire-resistant kaolin as the main raw materials through scientific compounding, shaping and high-tempreature calcination. Fire resistance ceramic ball has high mechanical strength and long using period, and refractory ceramic balls have good chemical stability and it connot have chemical reaction with materals, It has excellent high tempreature resistance and the highest heat-resistant tempreature can reach as high as 1900 °C. They are widely used in petrolem chemical ,fertilizer ,natural gas and environmental protection industry. With stable chemical features and a low rate of water absorption,they can resist high temperatures and high pressure,and also can resist the corrosion of acid,alkali and some other organic solvents,and can stand the change in temperature during the application.Ceramic balls can increase the distribution spots of gas or liquid, and to support and protect the activating catalyst with low strength.

Technical Specification :

Item | General | Corundum | Low silicate | |

Chemical composition | Al2O3 | 30-90 | 90-98 | ≥99 |

SiO2 | 10-70 | 0.5-5.0 | ≤0.3 | |

Fe2O3 | ≤1 | ≤0.5 | ≤0.1 | |

Refractoriness | ≥1450 | ≥1750 | ≥1850 | |

Thermal shock resistance, | 600 | 800 | 800 | |

Crushing strength,N | 100-20000 Deferent upon types and sizes | |||

Mohs hardness,scal | ≥7 | ≥8 | ≥9 | |

Acid resistance,% | ≥95 | ≥98 | ≥98 | |

Alkali resistance,% | ≥85 | ≥95 | ≥98 | |

Bulk density,kg/m3 | 1200-1600 | 1800-2000 | 2000-2200 | |