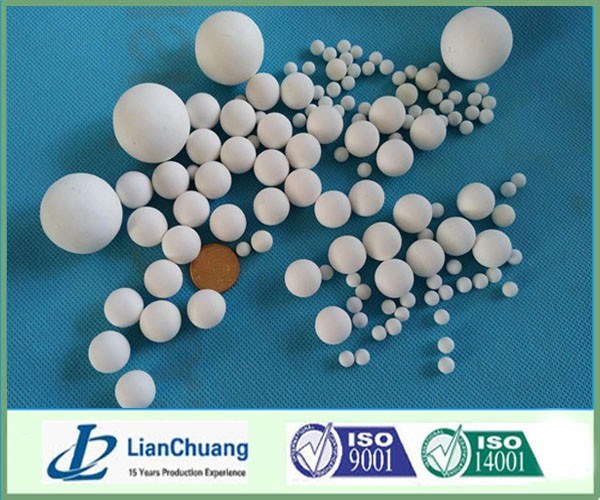

Product Description

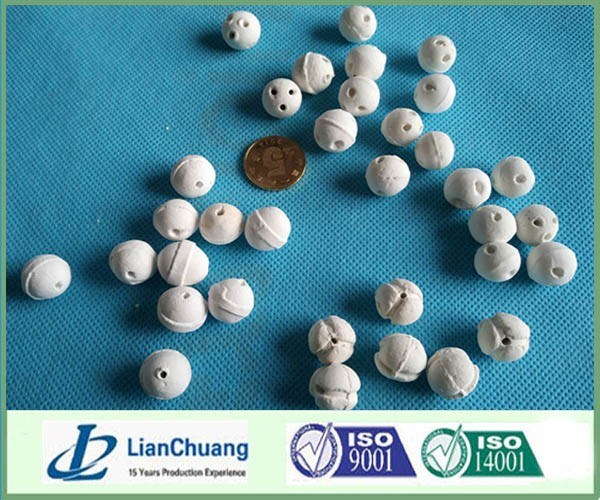

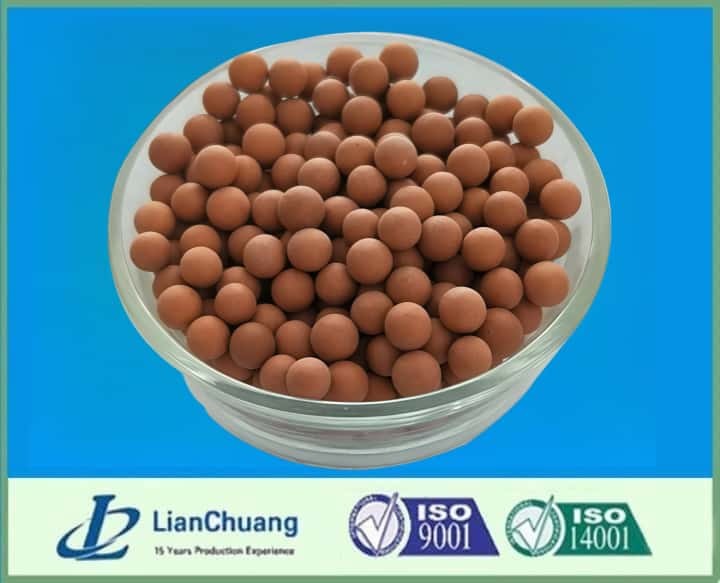

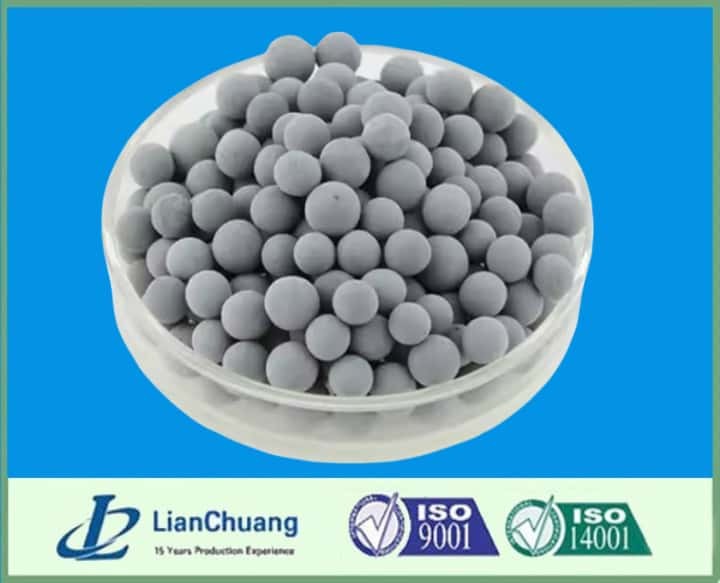

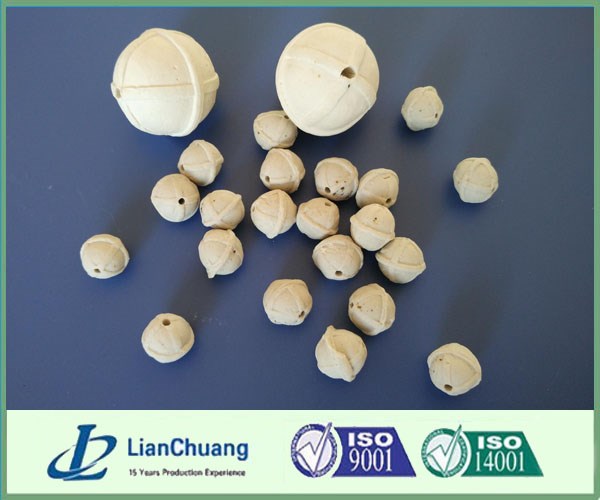

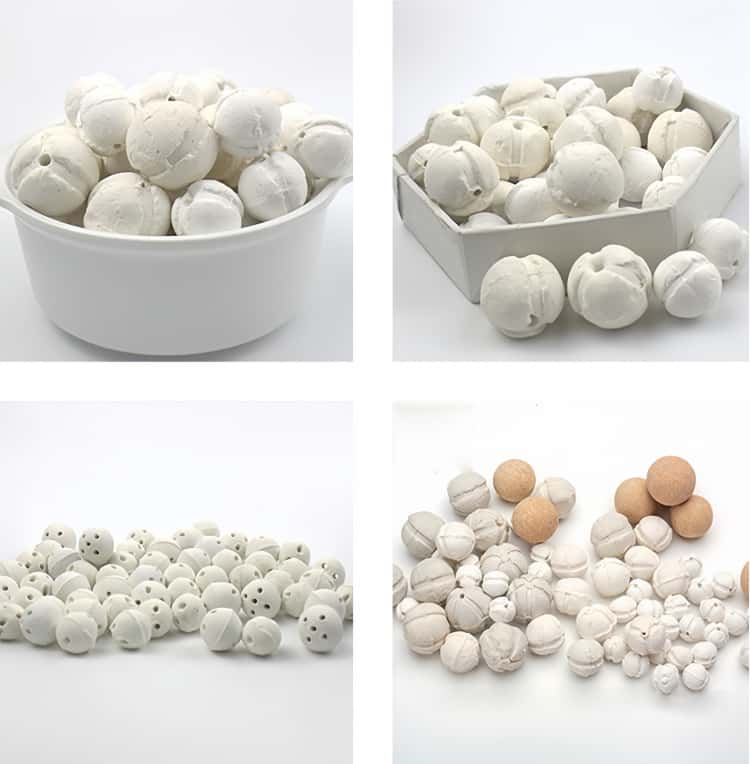

porous ceramic ball is also called filtering ceramic balls. It's developed on the basis of inert ceramic ball.holes drilled on the centre of the balls and achieving high stability and flexibility. Porous ceramic balls is It is made by make 20-30% pores inside the inert ceramic balls. Therefore it can be used not only for supporting and covering the catalyst, but also for filtering and eliminating the impurities of grain, gelatin, asphalting, heavy metal and iron ions of less than 25um. If the porous ball is set on the top of a reactor, the impurities fail to be eliminated in former process could be adsorbed in the pores inside the balls, there upon protect the catalyst and prolong the operating cycle of the system.As the impurities present in the materials are different, the user can select the product by their sizes, pores and porosity, or if necessary, add molybdenum, nickel and cobalt or other active components to prevent the catalyst from coking or poisoning. porous ceramic ball improves the void of the specific surface area, lowers the resistance of the system. It can replace normal ceramic balls used in oiling, chemical industry, and natural gas industries.

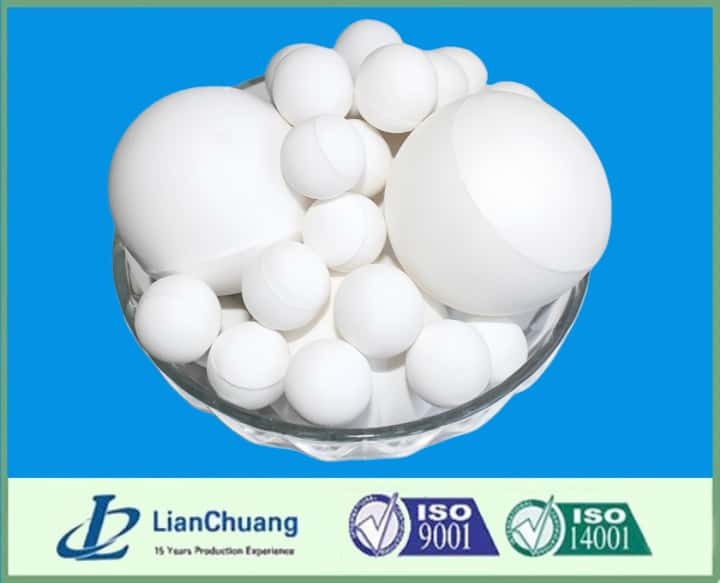

Comparing with inert ceramic ball,porous ceramic ball's structured pores with absorption function increased by 20-30% so that it can filter impurities in the oil.As oil impurities are in the form of granular, colloid,bitumen-like and heavy metals,part of them can be filtered out after going through raw material filter.It has an adequate mechanical strength, good chemical and thermal stability, ceramic porouse balls are a new efficient support and covering material of catalyst, it has been widely used in oil refinery, chemical, fertilizer, natural gas and environment protection industries since put into market.

Benefits of porous cearmic ball:

1. Catalyst will be protected to ensure unit operation and equipment run smoothly.

2. Prevent the catalyst from carbon-coking and poisoning.

Applications area of porous ceramic ball:

1.hydrogenation.

2.hydrogen production.

3.reformer.

4.diesel oil hydrogenation plant.

5.natural gas filtration.

6.compressed air filtration.

7.flour dust removal in carbon dioxide gas.

8.to filter organic solvent, decarburizing, hydrofining solvent.

9.quality of water filtration in oxydol production.

Specifications of Porous Ceramic Balls:

Item | LCA-1 | LCA-2 | LCA-3 |

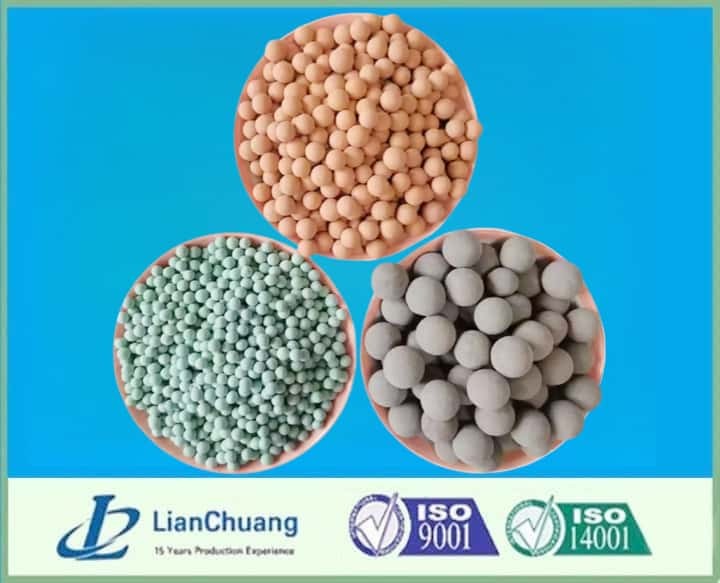

Al2O3(%) | 20 -80 | 20-80 | 20-80 |

Al2O3 + SiO2(%) | ≥90 | ≥90 | ≥90 |

Fe2O3(%) | ≤1 | ≤1 | ≤1 |

Pore diameter(um) | 0.5-35 | 40-100 | 110-1000 |

Porosity(%) | 20-30 | 15-25 | 15-25 |

Acid resistance(%) | ≥98 | ≥98 | ≥96 |

Alkali resistance(%) | ≥85 | ≥85 | ≥80 |

Heat shock resistance | 800°C | 800°C | 800°C |

Compressive strength | Depends on size | Depends on size | Depends on size |

Bulk density(kg/m3) | 1200 -1500 | 1200 -1500 | 1200-1500 |

Note:

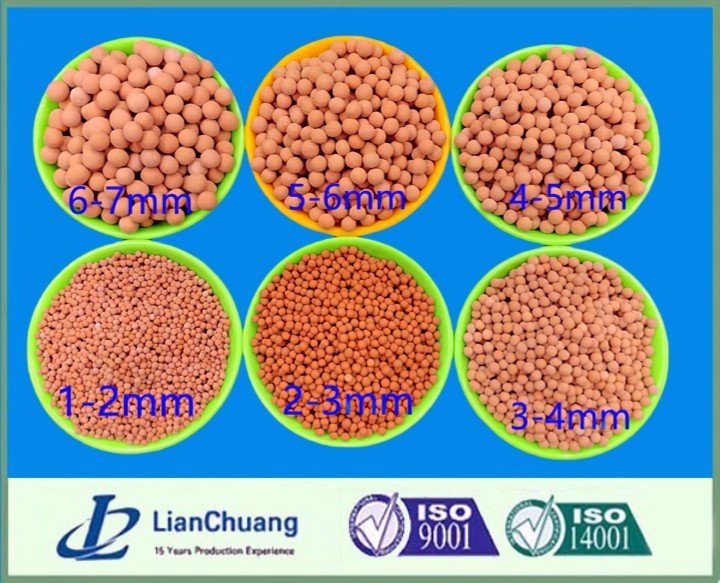

1. Varieties of specifications: the alumina composition content of porous ceramic balls from 25% to 80%, every 5% as a grade, divided into 12 varieties.

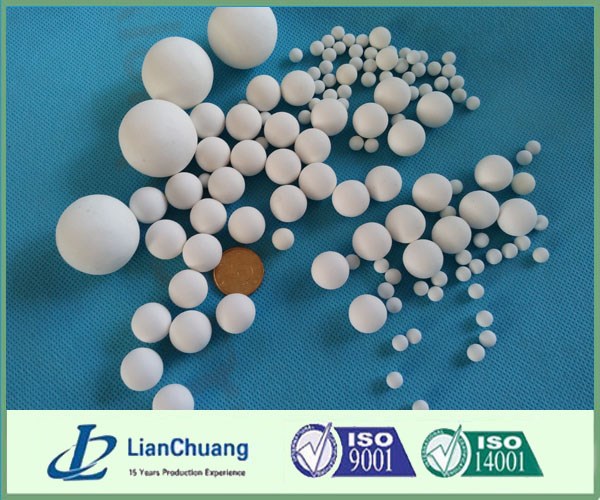

2. Specifications according to diameter could beφ3mm, φ6mm, φ8mm, φ10mm, φ13mm, φ16mm, φ20mm, φ25mm, φ30mm, φ38mm, φ50mm, φ75mm. Other shapes and specifications can be produced according to customer design requirements.