Product Description

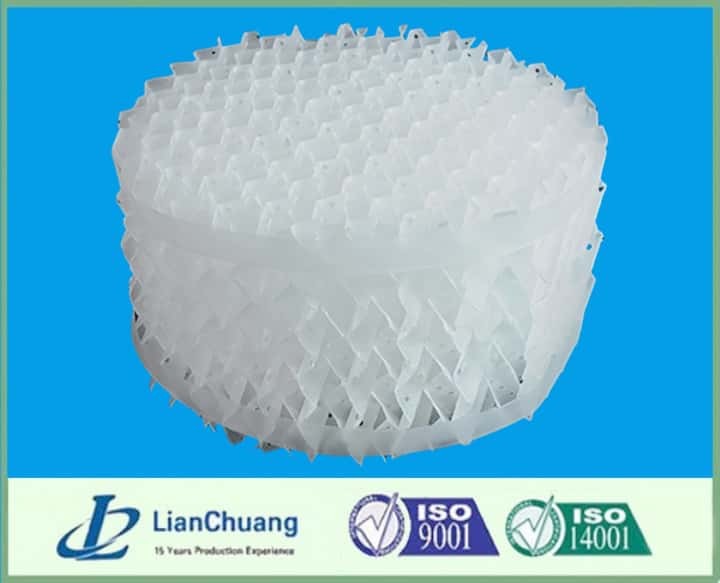

PP PE Plastic Demister Pad is an advanced gas-liquid separation device used in a variety of industrial applications, including petrochemical, oil, natural gas, and environmental protection. Manufactured from high-quality polypropylene (PP) or polyethylene (PE) materials, this demister pad offers excellent corrosion resistance, high-temperature durability, and long-term stability. It effectively removes droplets from gas streams, ensuring pure gas flow and improving overall production efficiency.

plastic wire mesh demister pad is made up of mesh blocks that filter vapor-liquid mixtures, effectively removing both large and small liquid droplets. It is widely used in environmental protection projects, such as flue gas desulfurization, and in industrial processes to eliminate water, mist, dust, and harmful substances, thereby purifying the air and protecting the environment.

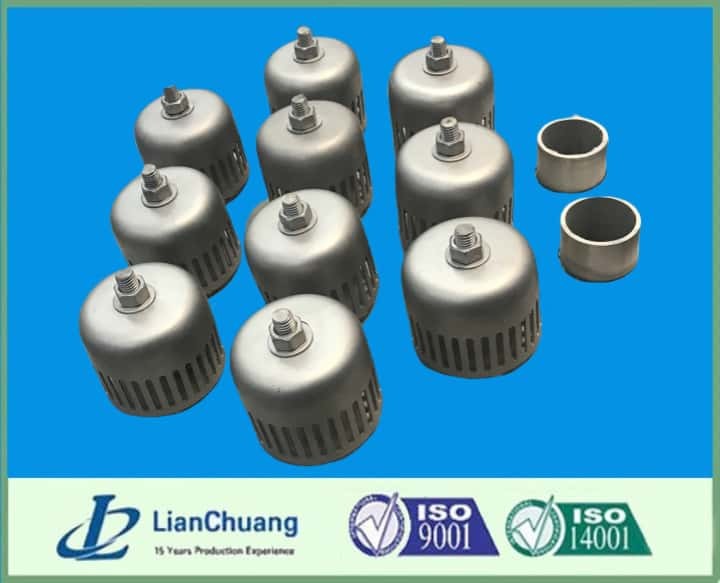

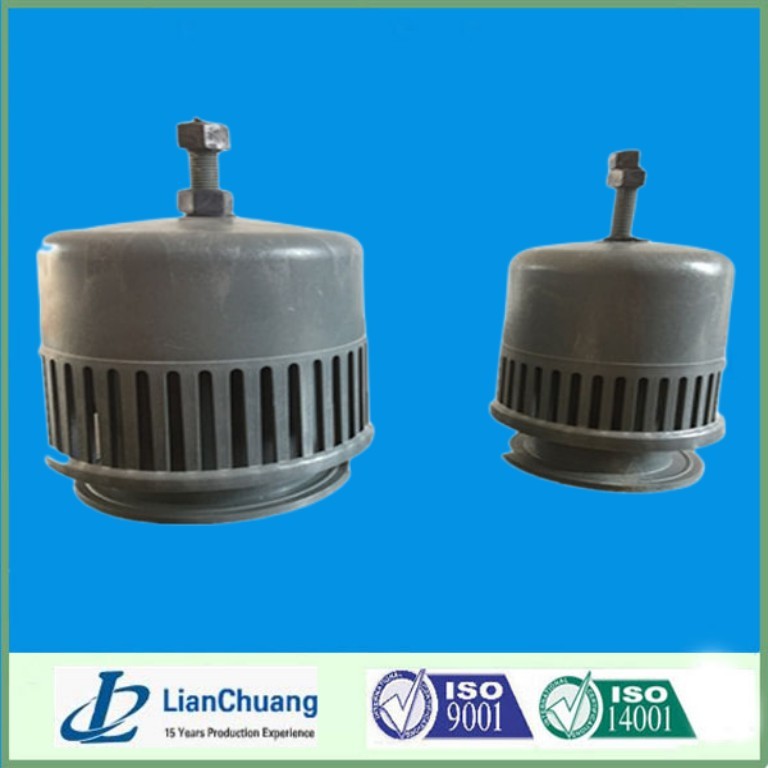

The defogger, installed in separation columns, ensures mass transfer efficiency, reduces material loss, and improves compressor performance after the tower. It effectively removes droplets as small as 3-5 microns and can be positioned between trays to improve efficiency and reduce board spacing. Plastic demister pad are commonly used in gas-liquid separators and air filters. Additionally, wire mesh helps protect instruments by buffering electronic interference in various industries.

The defogger, installed in separation columns, ensures mass transfer efficiency, reduces material loss, and improves compressor performance after the tower. It effectively removes droplets as small as 3-5 microns and can be positioned between trays to improve efficiency and reduce board spacing. Plastic demister pad are commonly used in gas-liquid separators and air filters. Additionally, wire mesh helps protect instruments by buffering electronic interference in various industries.

Types of Plastic Demister Pads:

1. According to Shape:

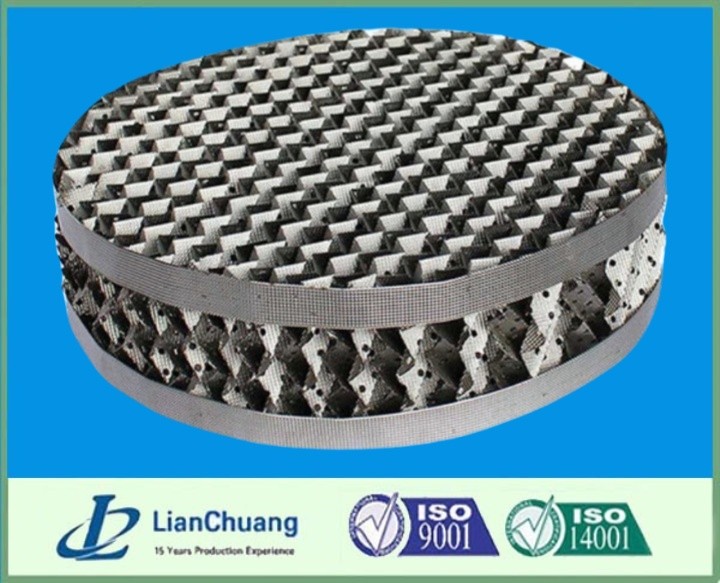

1. Round

2. Rectangular

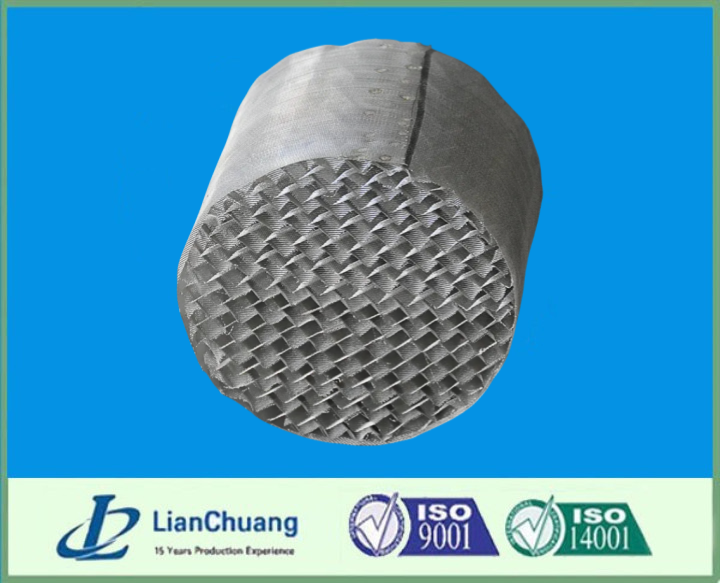

3. Ring

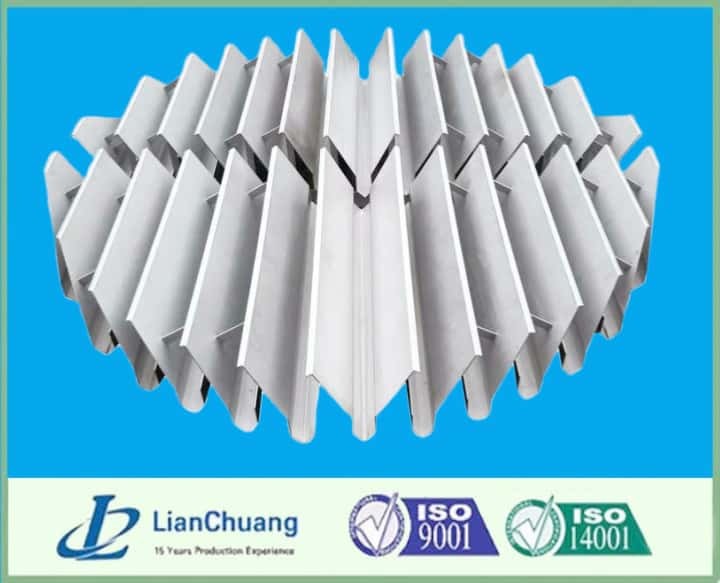

2. According to Structure:

1. Standard Plastic Demister Pad

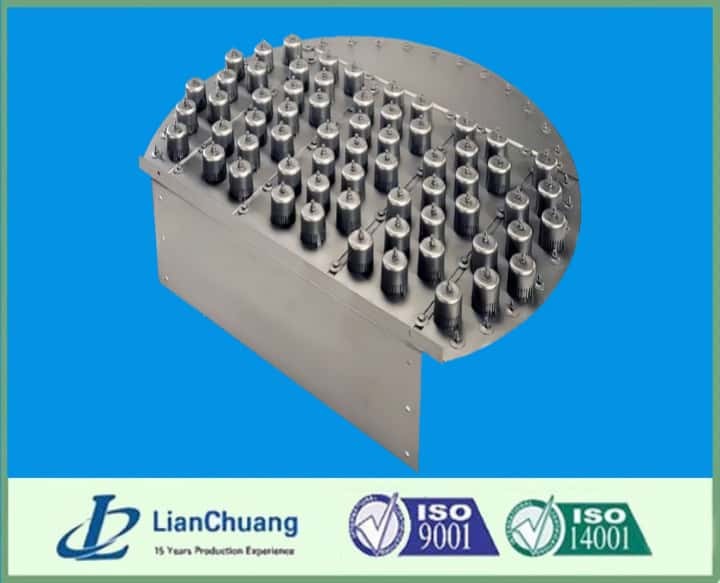

2. Drawer Plastic Demister Pad

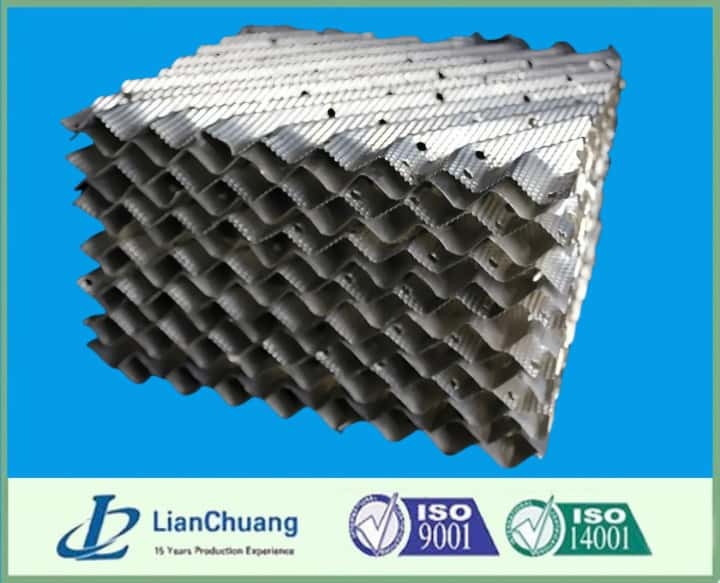

3. Wavelike Plastic Demister Pad

Key Features

1. High Temperature Resistance: The pp demister pad remains in excellent condition at temperatures up to 150°C.

2. Chemical Stability: plastic demister pad has outstanding resistance to corrosion, acids, alkalis, and various chemicals.

3. Low Pressure Drop: Ensures efficient gas flow with minimal energy consumption.

4. Strong Mechanical Properties: Offers good strength, hardness, and elasticity.

5. Excellent Separation Efficiency: High performance in separating liquid droplets from gas flows.

6. Ease of Installation and Maintenance: Convenient to install and uninstall, minimizing downtime.

Applications

1. Petrochemical: Essential for gas-liquid separation in petroleum refining processes.

2. Natural Gas Treatment: Removes liquid droplets from natural gas to improve gas quality.

3. Chemical Production: Vital in chemical processes requiring effective separation of gas and liquid phases.

4. Air Purification: Used in industrial waste gas treatment and gas purification systems.

5. Environmental Protection: The PP Demister Pad is commonly employed in flue gas desulfurization to filter out tiny liquid foam, ensuring cleaner emissions. It is also used in air purification and industrial applications to remove water, mist, dust, and harmful substances, contributing to environmental protection.

Technical Specifications

1. Material: Polypropylene (PP) or Polyethylene (PE)

2. Wire Diameter Options: 0.2 mm, 0.22 mm, 0.23 mm, 0.25 mm, 0.28 mm, 0.3 mm, 0.35 mm

3. Mesh Size: 2 mm x 3 mm, 4 mm x 6 mm, up to 12 mm x 6 mm

4. Height/Thickness: 100 mm to 150 mm

5. Pad Diameter: 300 mm to 6000 mm (customizable)

6. Pressure Resistance: Customizable based on your specific requirements

7. Applicable Gas Flow Rate: Tailored to suit various process conditions

Why Choose Us?

As a main manufacturer of PP PE Plastic Demister Pads, we offer high-quality, reliable products designed to provide superior gas-liquid separation in various industrial applications. Our pads undergo stringent quality control processes, ensuring that they meet the highest standards. Additionally, we provide competitive pricing to help you enhance efficiency, reduce failure rates, and lower operational costs.