Product Description

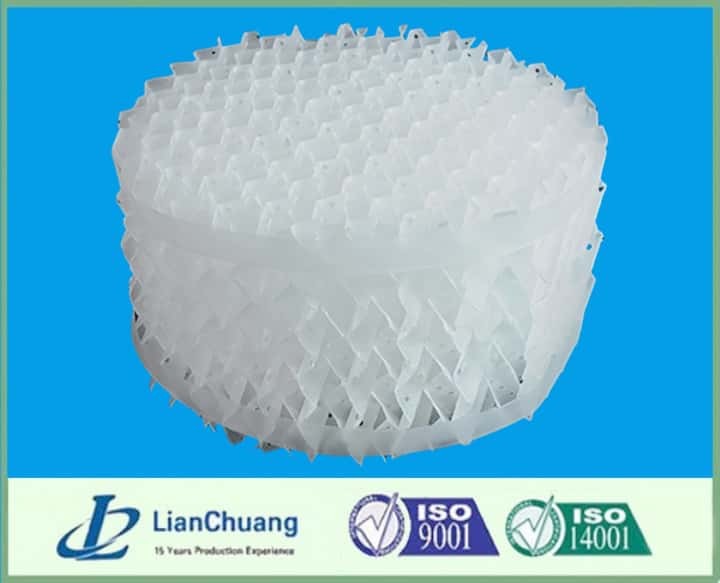

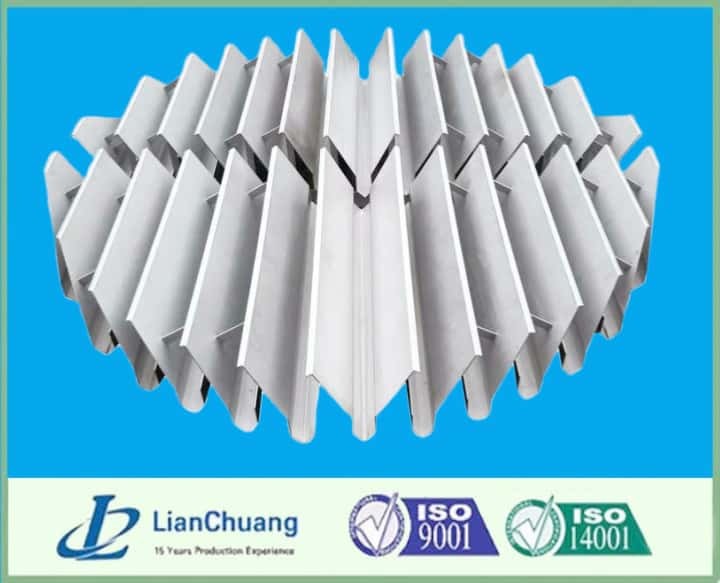

Polypropylene (PP) Demister Pad is a widely used vapor-liquid separation device, particularly popular for its efficiency in filtering liquid droplets or foam from gas streams. Composed of PP knitted wire mesh and gratings, the pp demister pad is an essential component for various industrial processes, ensuring effective separation of both large and tiny liquid foam particles suspended within a gas flow. This type of demister pad plays a critical role in ensuring high mass transfer efficiency and reducing the loss of valuable materials during industrial operations.

Functionality and Operating Principle

The PP wire mesh demister pad, also referred to as a wire mesh PP demister pad, operates primarily as a separator of vapor and liquid phases. It is frequently employed in chemical, petroleum, medical, light manufacturing, metallurgy, and environmental protection industries. These pads are especially effective in separating liquid droplets with diameters exceeding 3-5 μm in various separation towers. The operating mechanism works by allowing gas mixed with liquid droplets to rise at a specific velocity, passing through the wire mesh. As the gas rises, the inertia of the liquid droplets forces them to collide with the wire mesh, where they adhere to the surface. These droplets will gradually coalesce, forming larger droplets which then flow downward under gravity, aided by the wire mesh's capillary effect. This process ensures efficient liquid removal from the gas stream, maintaining the integrity of subsequent processing steps.

Variations of PP Demister Pads

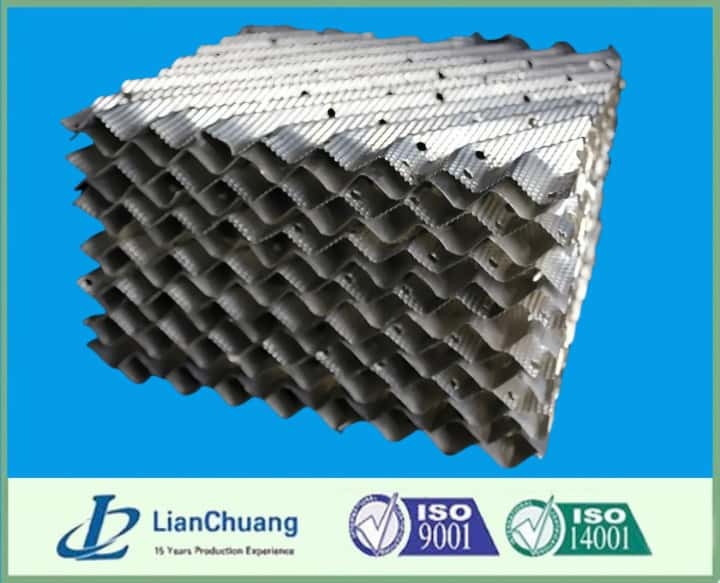

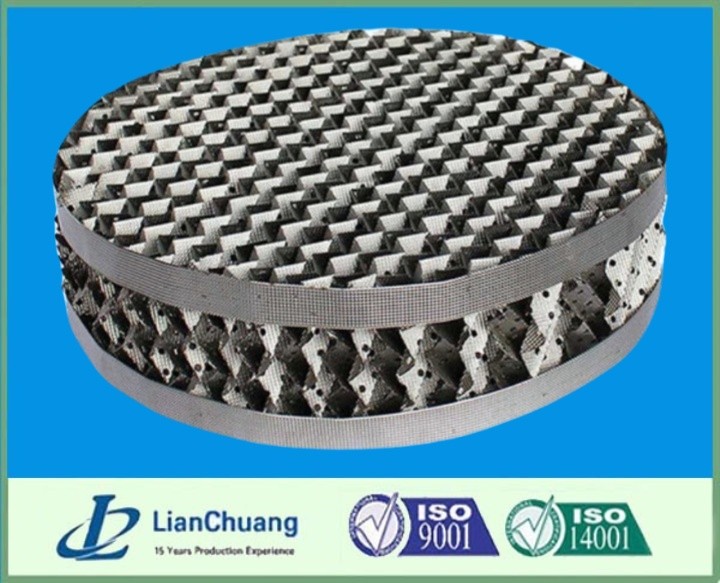

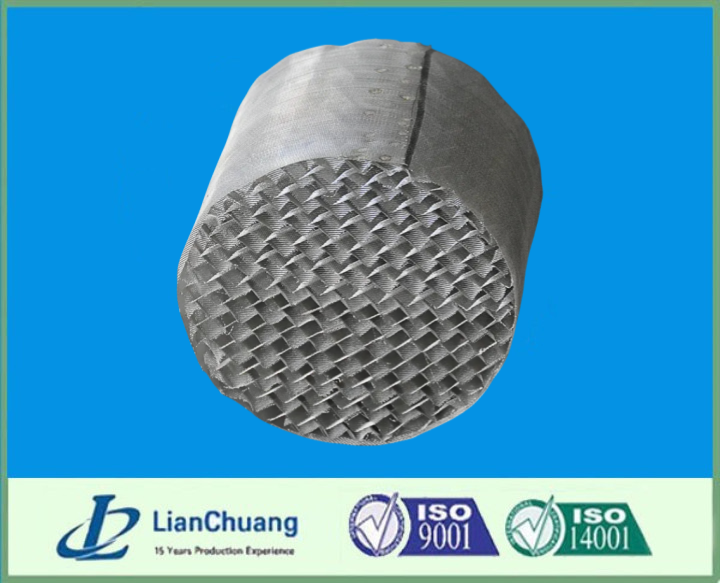

PP demister pads can be manufactured in various shapes to suit specific industrial requirements, including:

Round Shape

Rectangular Shape

Ring Shape

These versatile shapes ensure that the demister pads can be easily integrated into different systems depending on the installation requirements.

Primary Uses of PP Demister Pad

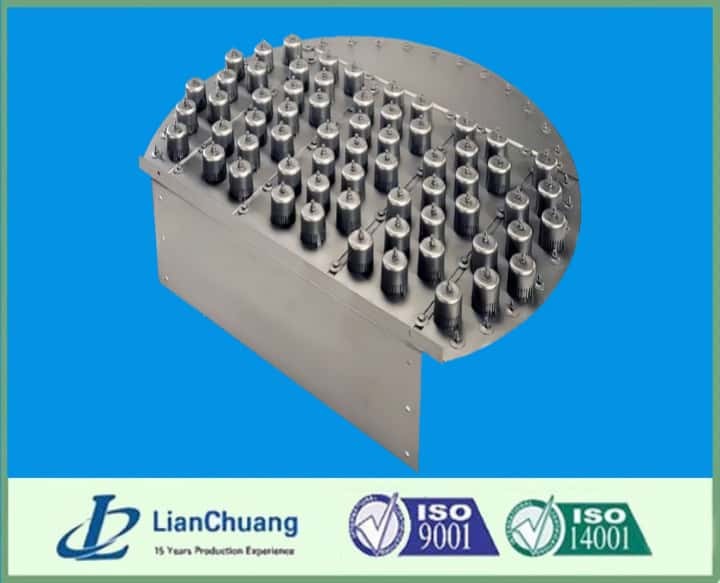

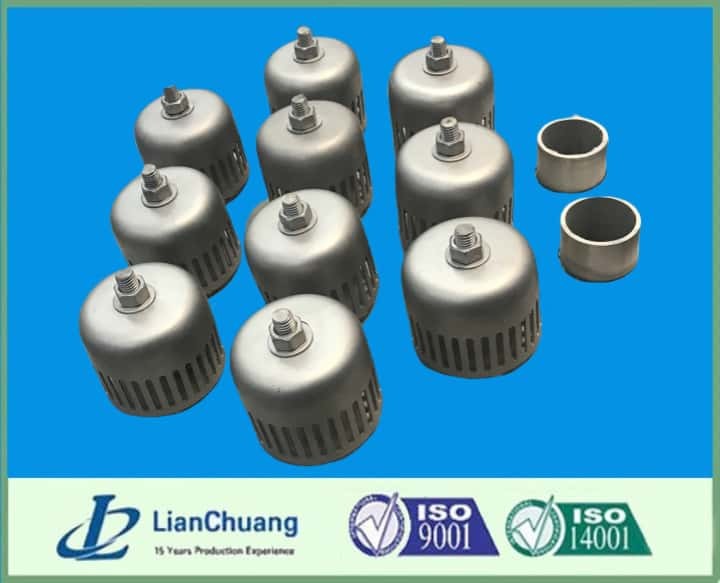

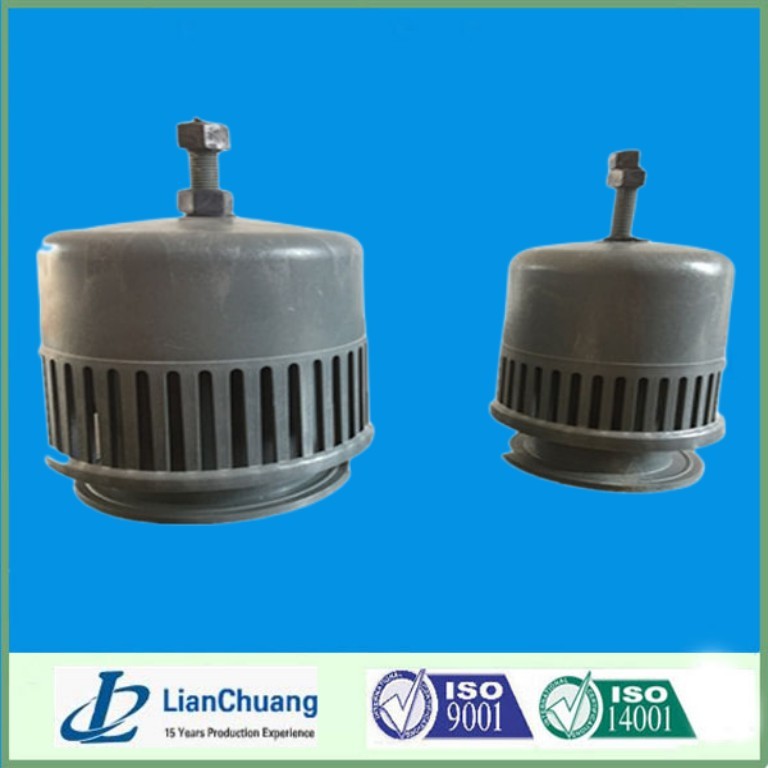

The PP demister pad is primarily used to eliminate entrained liquid droplets from gas streams in separation columns. It not only enhances mass transfer efficiency but also reduces the loss of valuable materials, optimizing the overall operation. It is especially effective in removing droplets as small as 3-5 μm. Additionally, the demister pad helps improve the operation of downstream compressors, and it is often positioned at the top of towers to maximize its separation efficiency. The mesh mist eliminator is crucial for gas-liquid separation processes, and it is also widely used in air filtration systems. In industrial settings, wire mesh serves as a buffer for sensitive instruments, preventing interference from electronic signals.

Features of Polypropylene Demister Pad

Polypropylene (PP) mesh demister pads are widely used in chemical processing and other industries where gas-liquid contact devices are employed. They are designed to remove liquid droplets from gas streams, ensuring that the quality of the gas or the next process step is not compromised. These demister pads offer several key features:

Inertial Collision Defogging: The primary separation mechanism, which ensures efficient removal of fog, vapor, oil, and gas.

Superior Gas-Liquid Separation: High separation efficiency allows for more effective filtering.

Simple Structure: Easy to install and maintain, with minimal complexity.

Porosity and Low Pressure Drop: Ensures minimal resistance to gas flow, enhancing efficiency.

Lightweight: With a density of 0.90 - 0.91 g/cm³, PP demister pads are among the lightest materials in plastics.

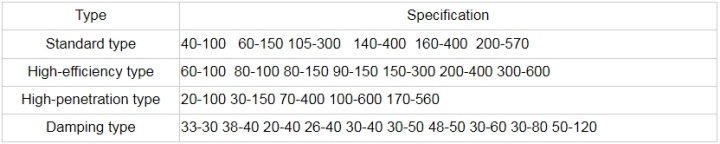

Specifications of PP Demister Pad

Performance Characteristics

PP demister pad offers excellent performance under various operational conditions:

Lightweight: The density of 0.90-0.91 g/cm³ makes it a lightweight option for industrial applications.

High-Temperature Resistance: PP demister pads can withstand temperatures up to 150°C, making them suitable for high-temperature processes.

Chemical Stability: These pads exhibit superior resistance to corrosion, acids, alkalis, and other aggressive chemicals.

Low Pressure Drop: The design minimizes pressure loss while maintaining high filtering efficiency.

Mechanical Properties: Good strength, hardness, and elasticity contribute to the durability of the pads.

High Efficiency: These pads are capable of efficiently filtering both large and tiny liquid droplets, making them ideal for a wide range of applications.

Scope of Using PP Demister Pads

PP demister pad is highly efficient in separating tiny liquid droplets, making it an essential component in environmental protection, particularly in flue gas desulfurization. Its ability to filter out water, mist, dust, and harmful substances makes it widely used in industrial processes to purify air and safeguard the environment.