Product Description

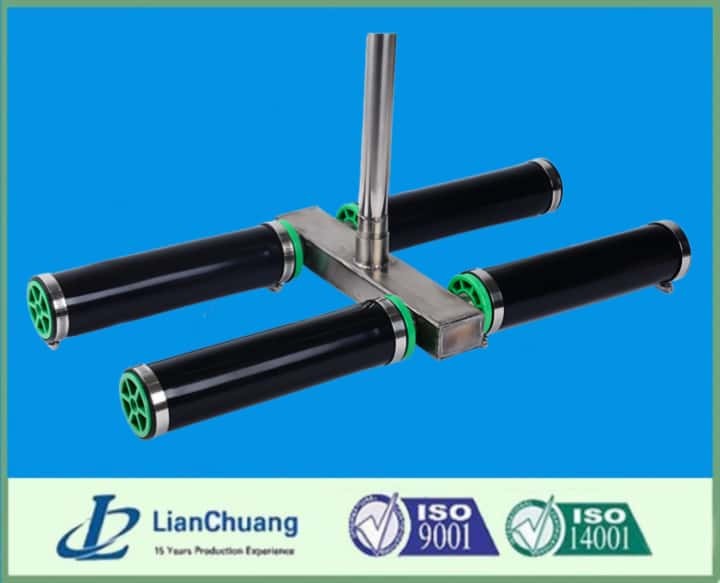

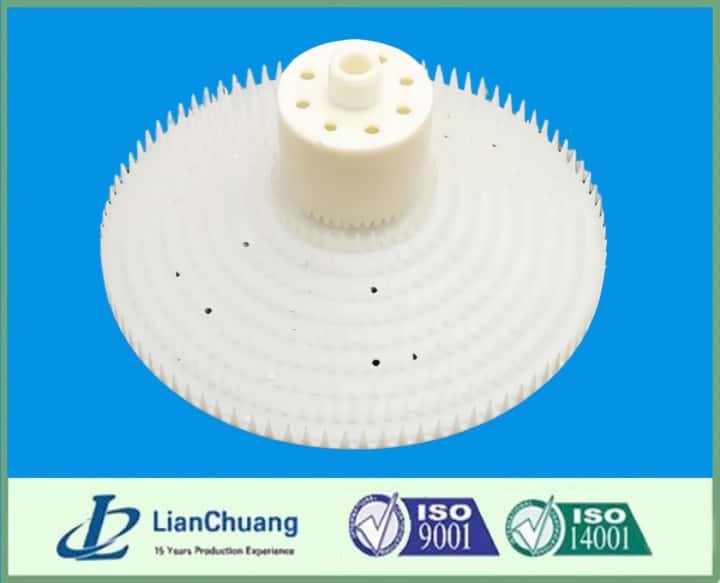

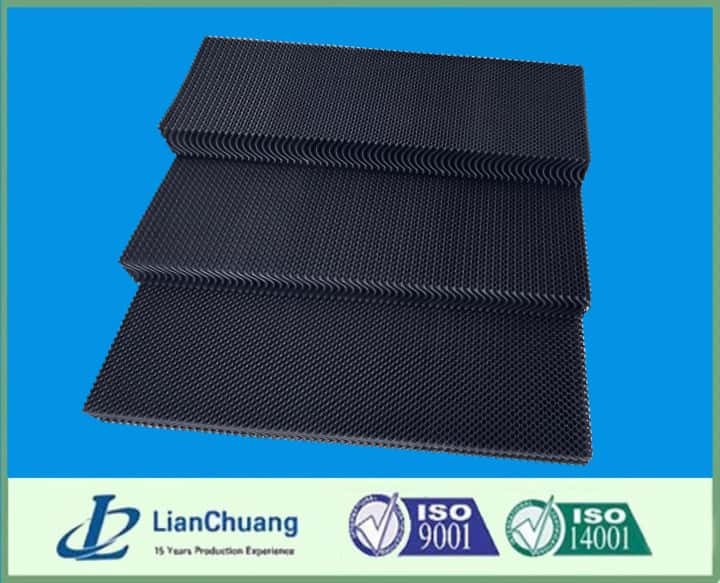

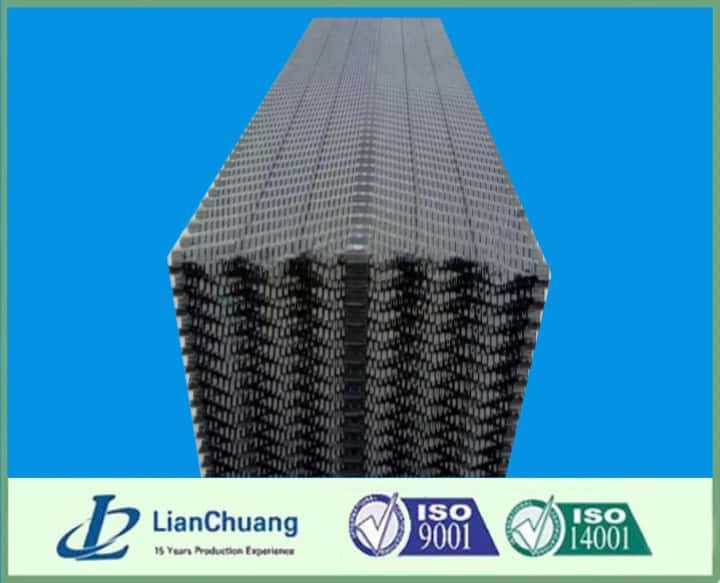

Marley cooling tower nozzles are engineered for industrial cooling towers, specifically designed to deliver hot water to the fill while ensuring optimal cooling performance. These nozzles play a pivotal role in enhancing heat transfer, energy efficiency, and overall system performance, making them a crucial component in cooling tower systems.

Key Features and Benefits:

Efficient Water Distribution: The Marley cooling tower nozzles utilize a unique jet design to ensure uniform distribution of water across the fill surface. This results in improved heat exchange, reduced energy consumption, and enhanced system efficiency.

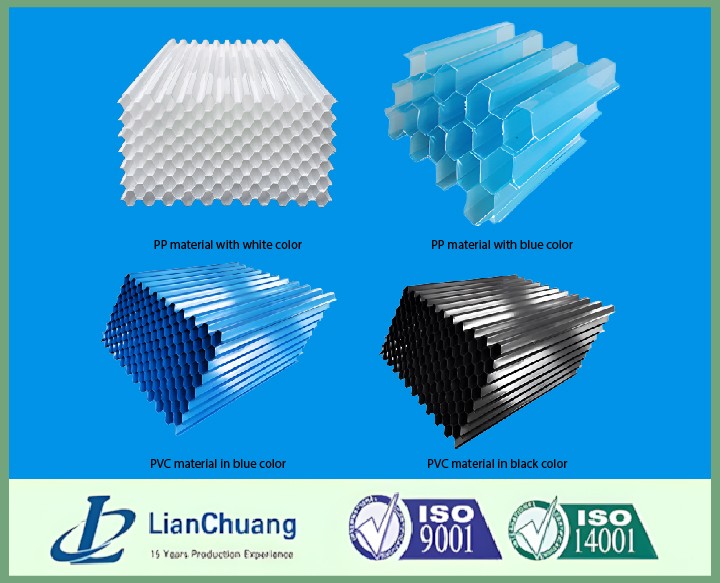

Corrosion-Resistant Construction: Made from high-quality, corrosion-resistant materials such as ABS plastic, stainless steel, or fiberglass-reinforced polypropylene, Marley nozzles are built to withstand the harshest environments. Their robust design guarantees long-term durability and reliable operation in extreme conditions.

Energy-Efficient Design: By accurately controlling the spray flow rate and nozzle angle, these nozzles optimize water distribution and minimize waste. This reduces water and energy consumption, helping businesses lower operating costs while maintaining high-performance standards.

Ease of Installation and Maintenance: With a modular design, Marley nozzles are quick and easy to install, and their straightforward maintenance requirements ensure minimal downtime. This feature translates into reduced maintenance costs and enhanced operational efficiency.

Versatile Compatibility: Marley cooling tower nozzles are adaptable to a wide range of cooling tower configurations, including counterflow and crossflow systems. This flexibility allows them to be used across various industries, from energy-intensive operations to manufacturing processes.

Specifications:

Material: Corrosion-resistant ABS plastic

Flow Rate: Customizable according to specific requirements

Spray Angle: Adjustable to optimize water flow distribution

Temperature Range: Suitable for use in temperatures ranging from -10°C to 80°C

Applications:

These nozzles are widely used in industries requiring high heat dissipation and uniform water distribution, including plating tanks, cleaning tanks, phosphating tanks, e-coat tanks, fertilizer tanks, pulp tanks, sludge tanks, paint booths, and anodizing tanks. Additionally, they are indispensable components in cooling towers, where efficient heat exchange is critical for operational success.

Conclusion:

marley cooling tower spray nozzles are engineered for superior performance, durability, and energy efficiency. Their ability to improve heat exchange, reduce water wastage, and enhance system longevity makes them an essential element in modern cooling tower operations. Whether used in industrial applications or demanding environmental conditions, these nozzles help ensure the reliable and efficient functioning of cooling systems, offering significant cost savings and improved productivity.