Product Description

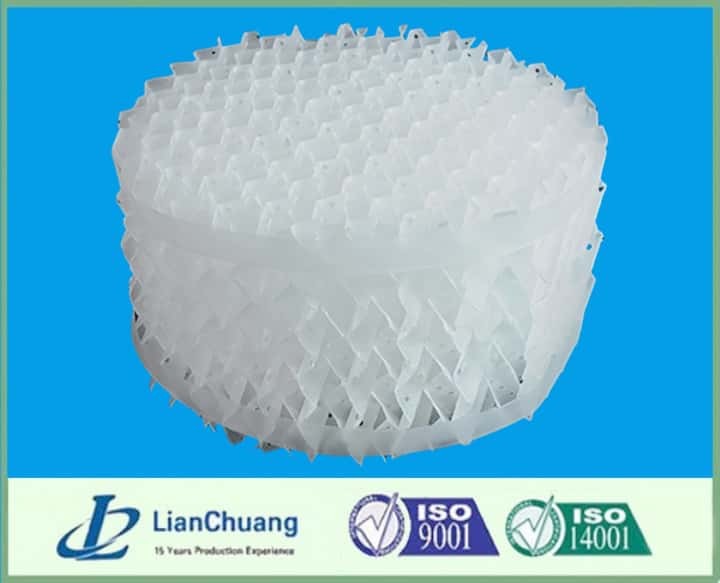

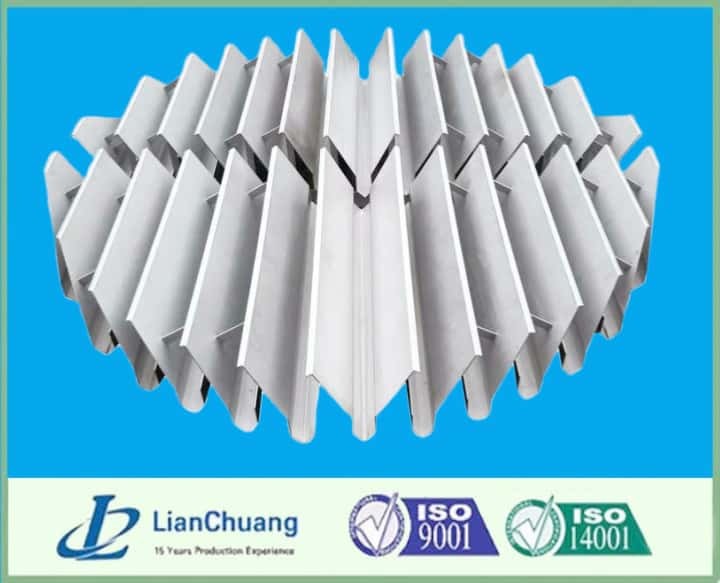

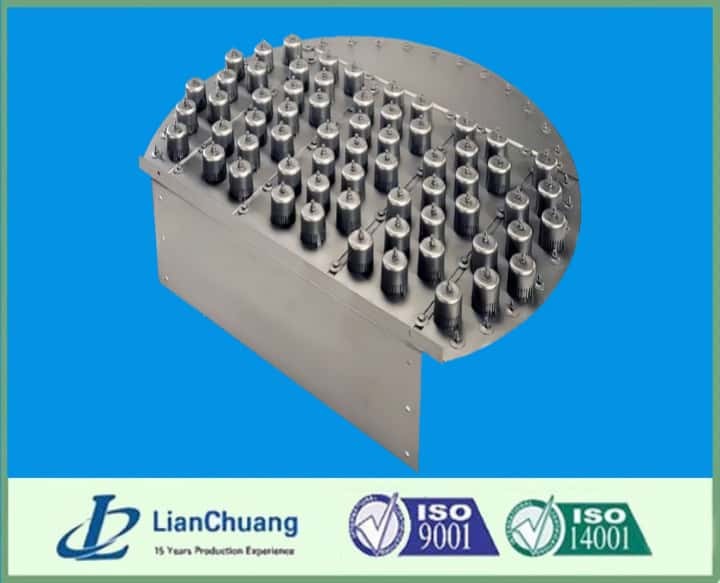

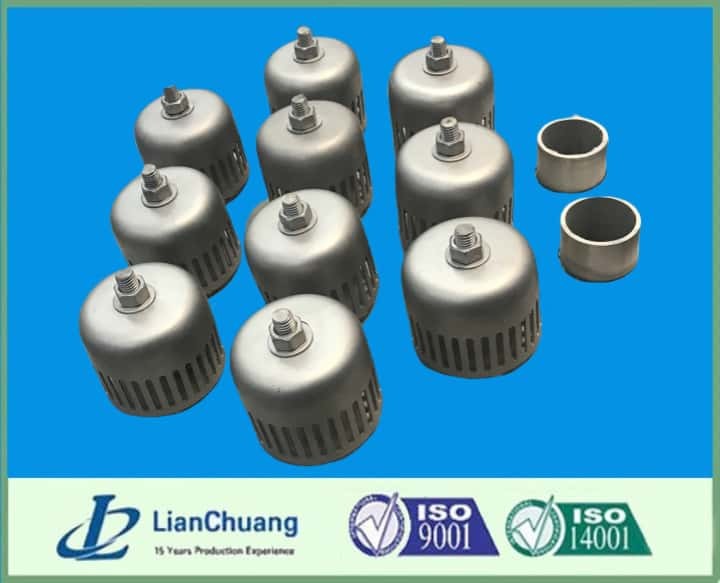

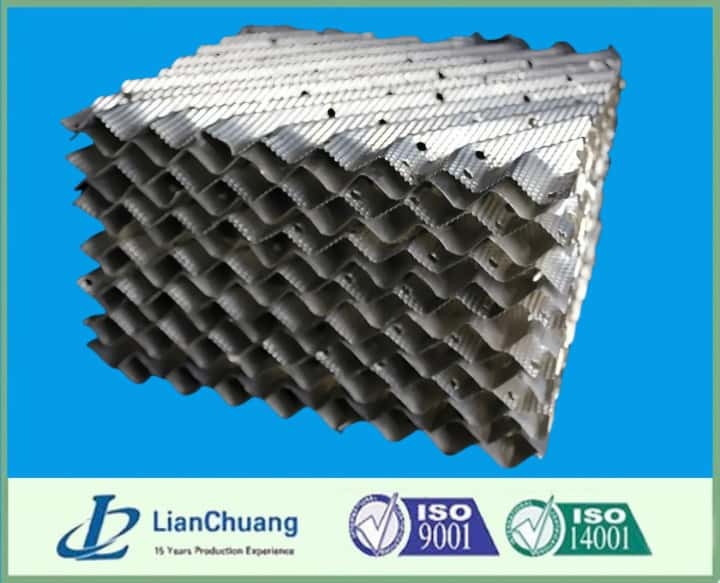

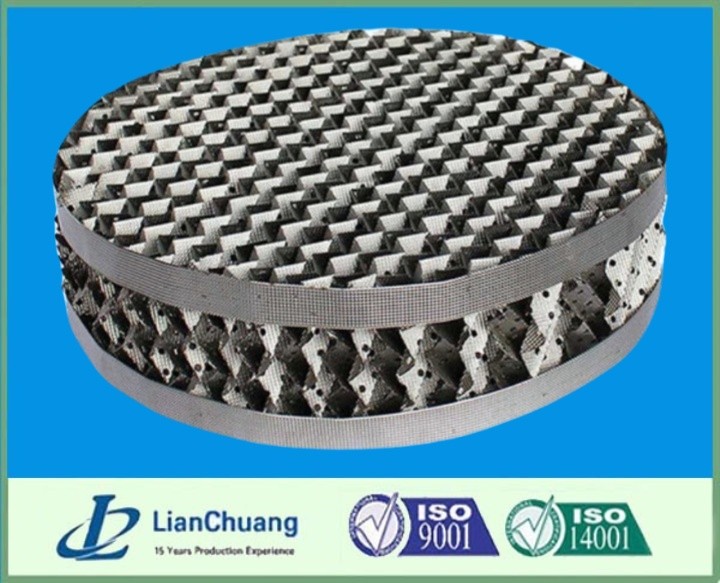

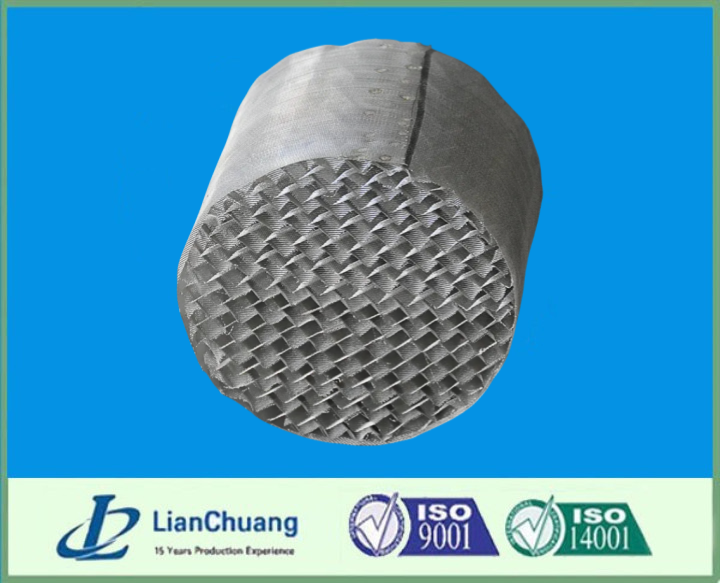

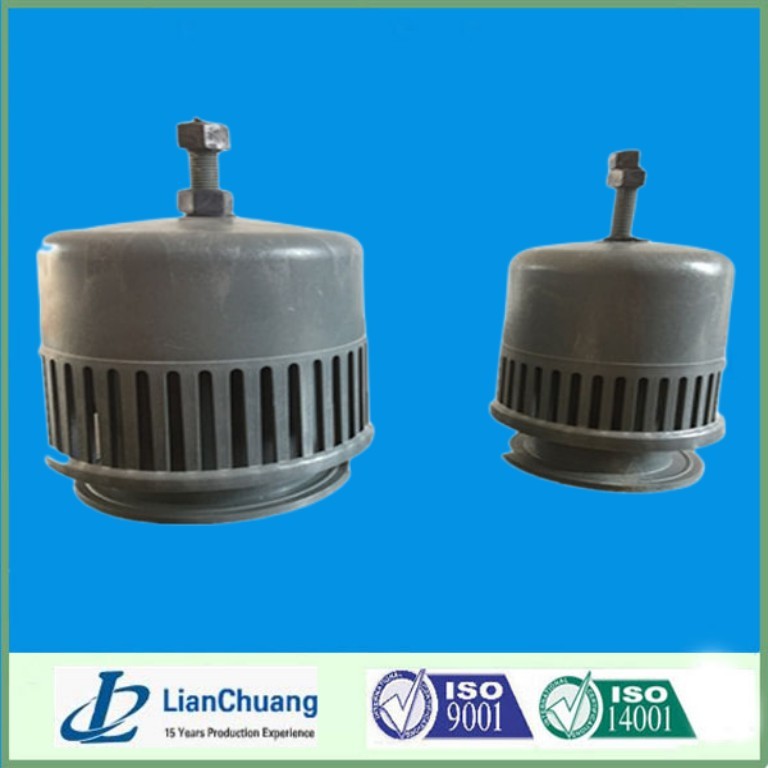

Knitted Mesh Stainless Steel Demister Pad is a highly efficient and durable solution for separating liquid droplets from gas streams in industrial applications. It is widely used for the removal of liquid particles from exhaust air, exhaust gases, and steam. Constructed using high-quality stainless steel wire mesh, this demister pad ensures reliable and effective mist removal, protecting downstream equipment and improving overall process efficiency. stainless steel demister pad designed to perform in demanding environments, the knitted mesh structure offers excellent corrosion and heat resistance, making it ideal for use in chemical, petrochemical, oil & gas, power generation, and other heavy industries. The separation efficiency improves with increasing flow velocity and is influenced by the voids and wire mesh surface area.

Key Features

1. Absolute separation of larger liquid particles: Efficiently separates larger liquid droplets from gas streams, ensuring clean and dry gases.

2. Suitable for extreme temperature and pressure conditions: Designed to operate under high temperatures and pressures, making it versatile for demanding industrial applications.

3. Minimal pressure loss: Offers low pressure drop to minimize energy consumption during operation.

4. Excellent separation efficiency: High efficiency, with up to 99% mist removal, even under challenging operating conditions.

5. Maximum inflow area: Maximizes gas flow while ensuring efficient mist separation, thanks to the optimized design.

6. Corrosion resistance: Can withstand highly corrosive environments, making it suitable for aggressive media.

7. Durable construction: Made from high-quality materials like stainless steel, aluminum, and tinned copper steel, ensuring long-lasting performance.

Advantages of Stainless Steel Demister Pad

1. High removal efficiency.

2. Negligible pressure drop, less than 25mm of water gauge.

3. No maintenance or service required.

4. No corrosion or temperature limitations.

5. Easily installed in existing vessels.

6. No limitation on size or shape.

Applications

1. Chemical and Petrochemical Industries: Essential in reactors, distillation columns, and scrubbers for removing mist and ensuring the purity of gas streams. Helps protect valuable downstream equipment from liquid damage and improves overall process efficiency.

2. Oil and Gas Industry: Used in gas-liquid separation systems, the demister pad ensures clean gas by removing water, oil, and other contaminants, protecting sensitive equipment like compressors and turbines.

3. Power Plants: Plays a crucial role in flue gas desulfurization and emission control systems, ensuring that exhaust gases are mist-free, which reduces the risk of corrosion in downstream systems.

4. Food and Pharmaceutical Manufacturing: Used in mist elimination systems in food and pharmaceutical production environments to maintain hygiene and product quality by preventing contamination from airborne droplets.

5. HVAC Systems: Effective in air filtration systems where removing moisture and mist is crucial for preventing corrosion in HVAC components and ensuring air quality in industrial and commercial buildings.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Stainless Steel (SS304, SS316, SS316L, or customized alloys), Aluminum, Tinned Copper Steel |

| Mesh Type | Knitted wire mesh design for superior mist removal efficiency |

| Dimensions | Custom sizes available based on customer specifications |

| Pressure Drop | Low pressure drop for minimal energy consumption |

| Flow Capacity | Custom flow capacities based on design and application |

| Thickness | Customizable based on operational requirements |

| Wire Diameter | 0.11 mm, 0.13 mm, and other diameters available |

| Type | Common type, compressed type |

| Weave Type | Crochet weaving |

| Manufacturing Method | Machine knitting |

| Packing | Waterproof Paper and Cartons |

| Shipment Date | 15 days |

Customization Options

Why Choose Knitted Mesh Stainless Steel Demister Pad?

Efficient Mist Removal: Provides reliable and high-efficiency mist separation to improve the quality of gas streams and protect downstream equipment.

Long-lasting Performance: Manufactured from high-quality stainless steel, ensuring durability and performance in challenging industrial environments.

Customizable Solutions: Flexible design options to suit a wide range of applications, ensuring optimal performance.

Low Operational Costs: Reduced maintenance and energy consumption due to the low pressure drop and robust construction.