Product Description

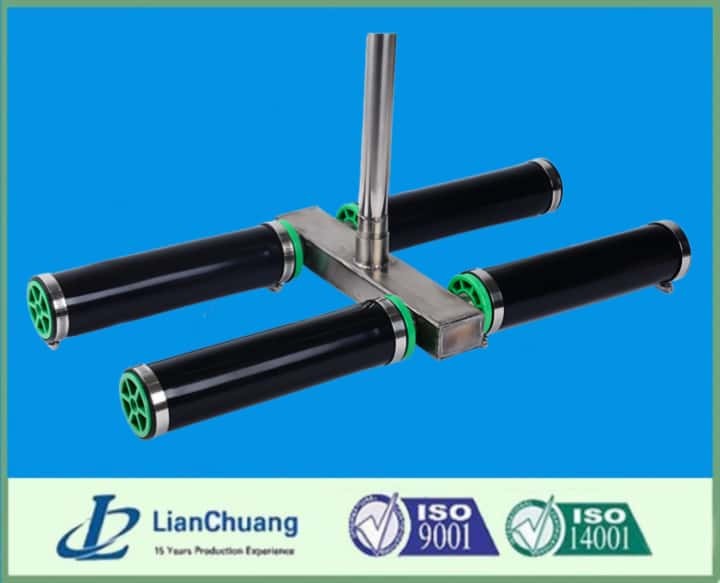

Effectively designed cooling tower distribution nozzles help ensure uniform water distribution over the cooling tower fill. Even water distribution at the top of the cooling tower fill is critical for proper wetting of the entire fill surface. cooling tower spray nozzles can either be fixed in place, spraying a circular or square pattern, or they may be part of rotating components in certain crossflow cooling towers.

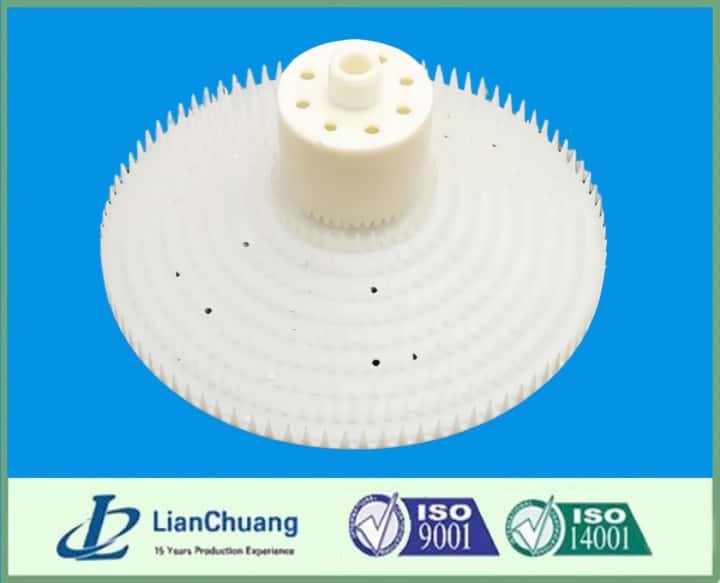

PP AccuSpray Nozzles for Counterflow Cooling Tower is specifically designed for counterflow cooling tower applications, offering an efficient solution for optimized water distribution and cooling performance. With its unique spray pattern, the PP AccuSpray Nozzles for Counterflow Cooling Tower ensures uniform water dispersion while maintaining low operating pressure. Made from durable polypropylene, this nozzle is built to last, providing long-term reliability and strength for your cooling system.

Key Features and Benefits:

- Dual Splash Plate Design: The innovative design maximizes thermal performance by ensuring even water distribution, improving overall cooling efficiency for your tower.

- Clog-Resistant: The AccuSpray nozzle is engineered to resist clogging, ensuring smooth and consistent water flow, minimizing maintenance needs.

- Durability: Crafted from high-strength polypropylene, this nozzle is built to withstand the demands of continuous operation, offering a long lifespan and reducing replacement costs.

- Wide Range of Orifice Sizes: AccuSpray nozzles are available in orifice sizes ranging from ½” to 1-1/2” (13mm to 38mm), with color-coded options that make inspection and maintenance easier and more efficient.

- Ideal for Retrofit and Upgrades: Whether you're working on a new installation or upgrading an existing system, the AccuSpray nozzle is the perfect solution for improving the performance and efficiency of your counterflow cooling tower.

- RC Thread Design: The nozzle features an RC thread that requires fewer turns to fully seat, making installation faster and easier. Its design significantly reduces the chance of cross-threading, ensuring a secure and reliable fit.

Why Choose Us

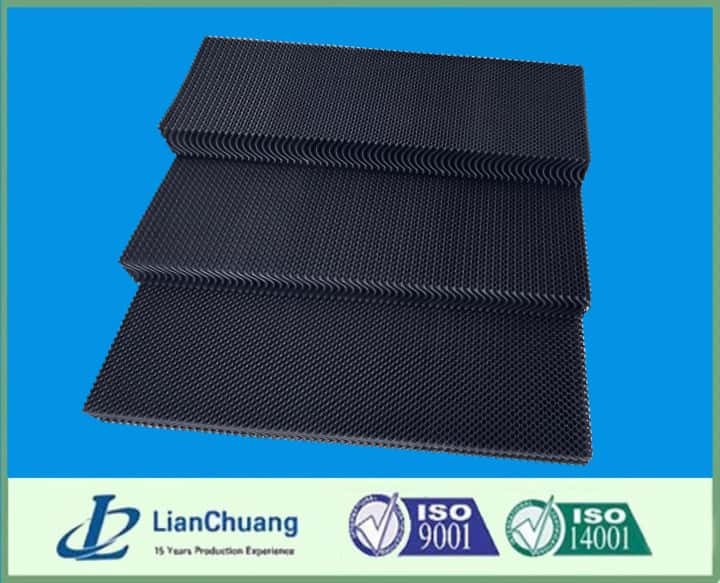

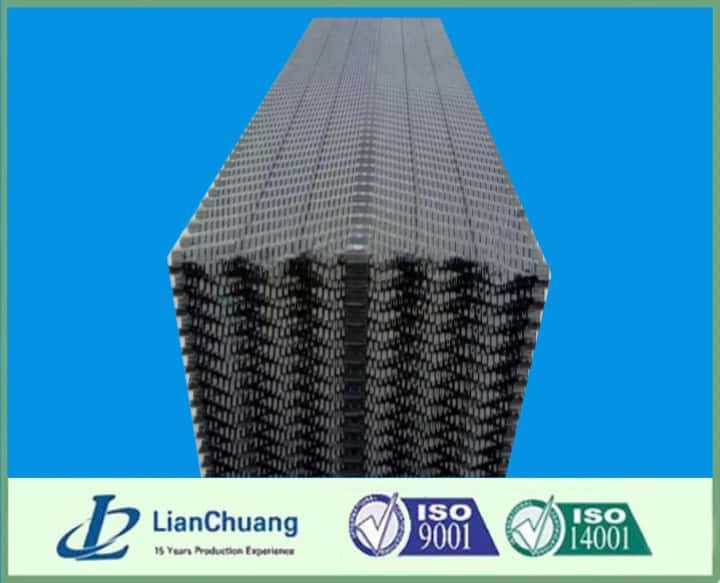

All cooling tower nozzles we offer are designed, developed, and tested in our test rooms and laboratories. After software modeling, these cooling tower nozzles undergo sample testing. Extensive testing is conducted to achieve optimal water distribution over the cooling tower fill under varying flow conditions, including flow coefficient, reduced pressure drop, and wear tests. Additional testing is also carried out at pilot plants to provide further design data. As the core of the heat exchange process, the cooling tower fill relies on the efficiency achieved by effectively designed cooling tower distribution nozzles.

Our factory's cooling tower distribution nozzles provide versatility, high reliability, and exceptional performance.