Product Description

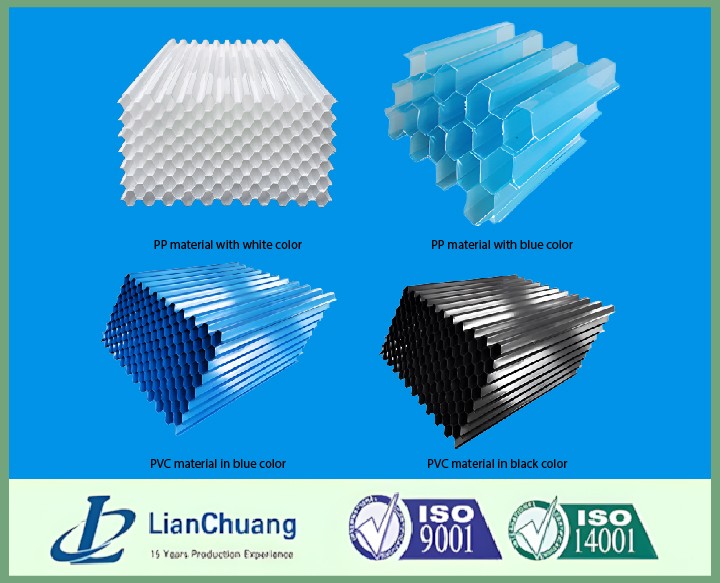

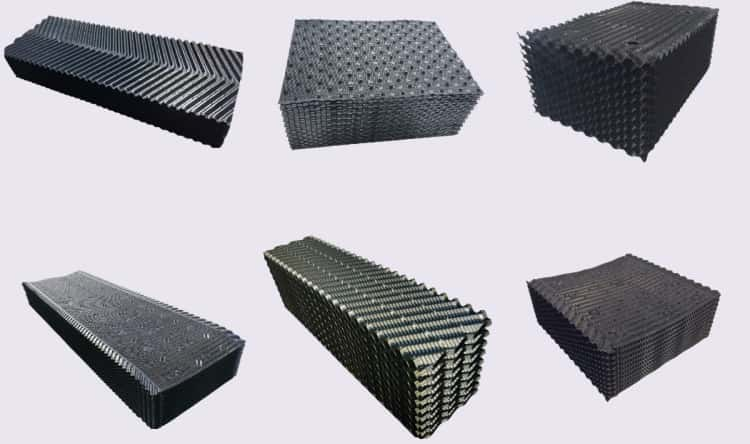

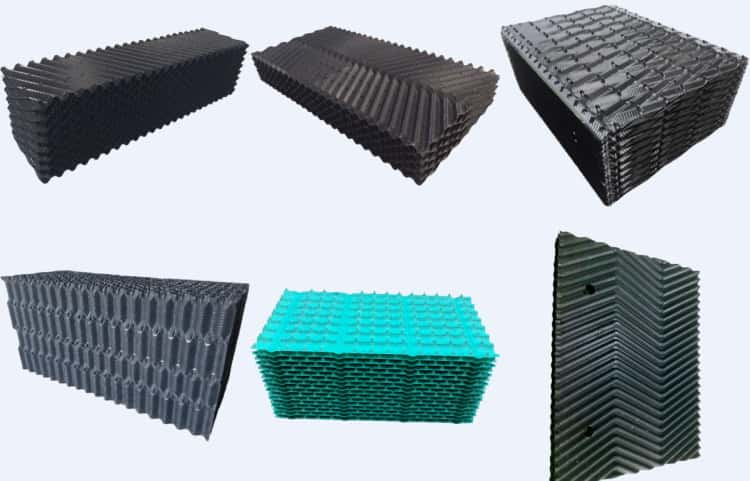

Cooling tower fill is the most crucial component of a cooling tower. cooling tower fill is fundamental for increasing the contact surface area and contact time between air and water, which enhances heat transfer efficiency. The overall performance of the cooling tower is highly dependent on the condition of its fill. Indicators such as holes in the fill can signify issues like broken or missing nozzles, or cracked and separated lateral piping. Given that the majority of heat transfer takes place in the fill area, it is essential for customers to carefully consider various fill styles and types. We provide unbiased, independent thermal ratings to help maximize the efficiency of their cooling towers.

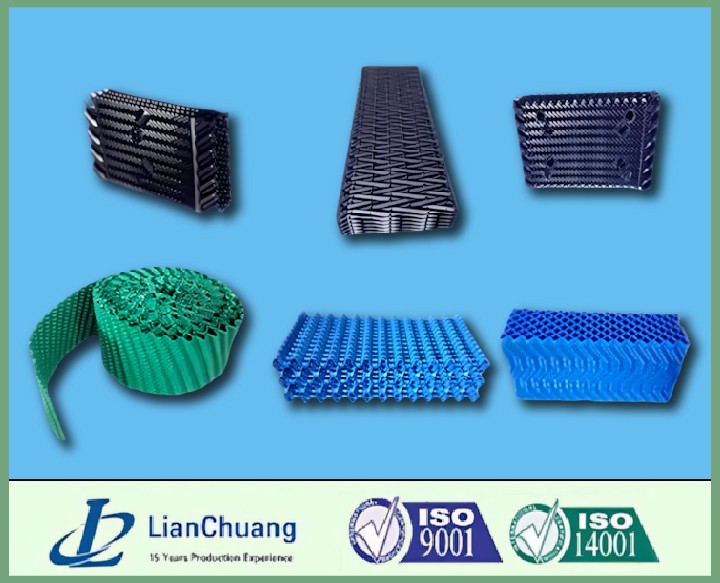

Cooling Tower Product Categories

Depending on the direction of water and air flow, cooling tower fills are primarily categorized into Crossflow Fill and Counterflow Fill. Below is a detailed introduction to these two types of fills and their applications.

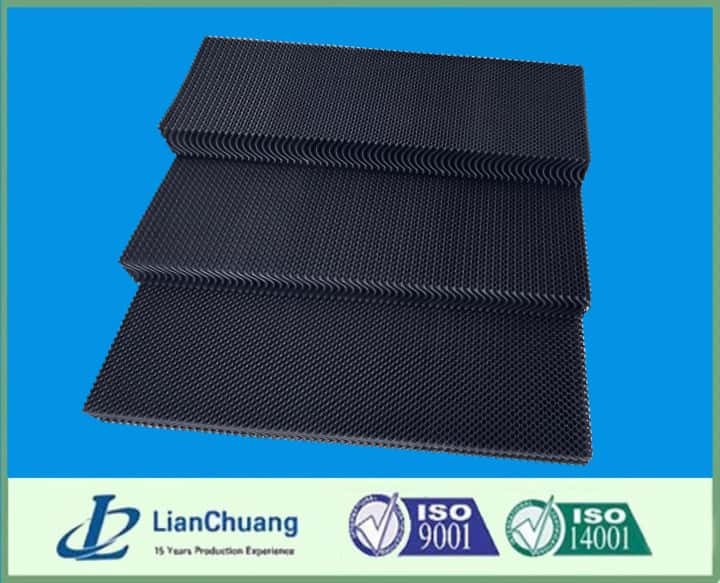

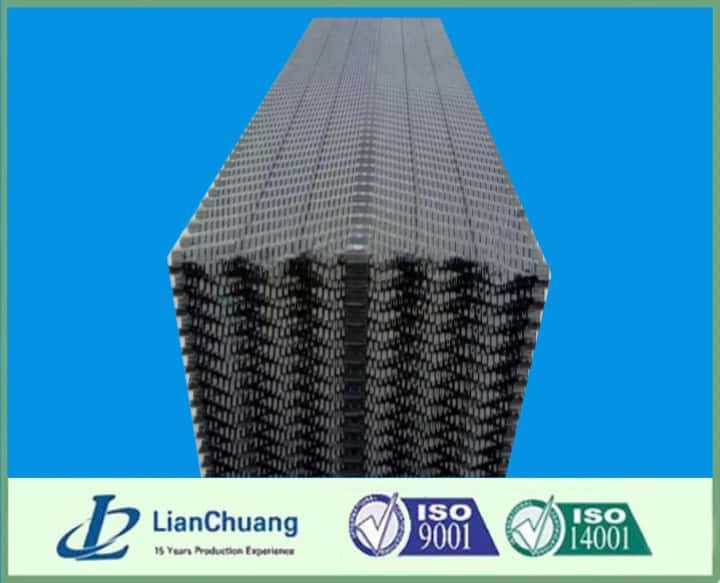

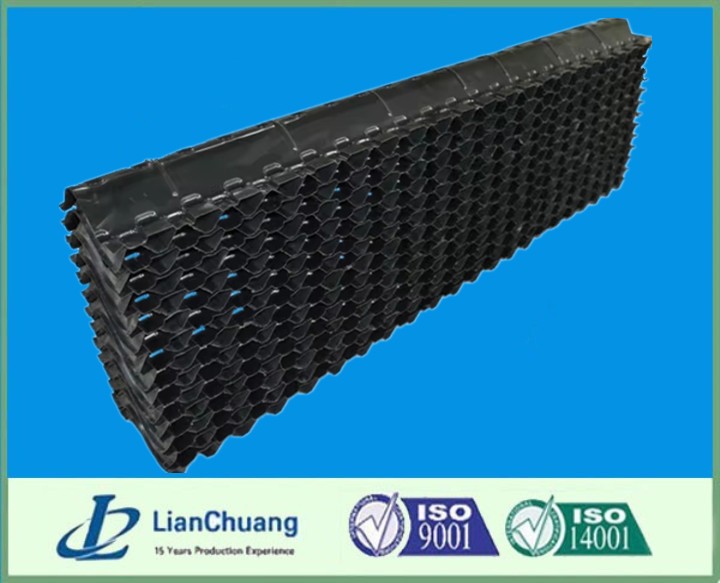

1. Crossflow Fill

Crossflow Fill refers to a design where water flows vertically downward through the fill, while air passes horizontally across the fill. This type of fill is simple in design, easy to install and maintain, and is suitable for cooling towers handling large volumes and high-temperature water.

Crossflow Fill refers to a design where water flows vertically downward through the fill, while air passes horizontally across the fill. This type of fill is simple in design, easy to install and maintain, and is suitable for cooling towers handling large volumes and high-temperature water.

Features:

High Heat Transfer Efficiency: Due to the different flow directions of water and air, the contact area and contact time between the two are increased, thus enhancing heat transfer efficiency.

- Structural Design: Crossflow fills are usually thin sheets or corrugated structures arranged at specific angles to increase turbulence between air and water, further improving cooling effects.

- Convenient Maintenance: With shorter water flow paths and gravity-driven water flow, the likelihood of fill clogging is lower, making maintenance and cleaning more convenient.

Application Scenarios:

- Large Industrial Cooling Towers: Crossflow fills are commonly used in large industrial cooling towers such as power plants and petrochemical plants, handling high-temperature and large-volume cooling water.

- Commercial Building Cooling Towers: Suitable for places requiring efficient heat dissipation, such as shopping centers and large office buildings.

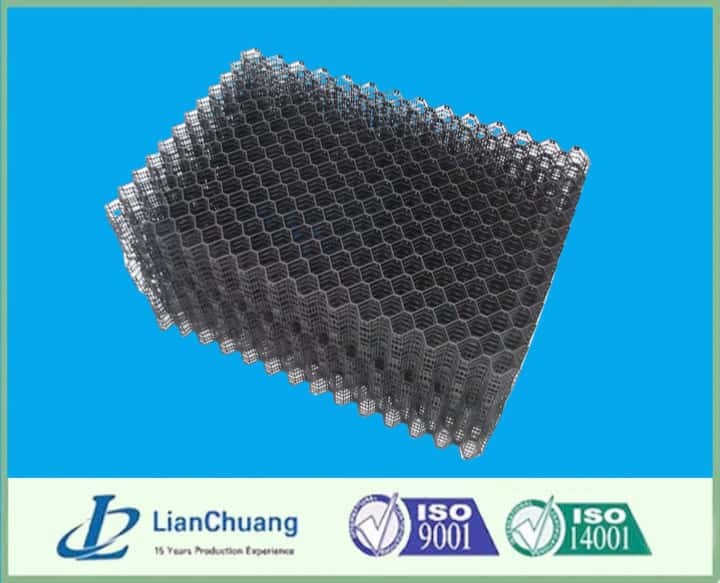

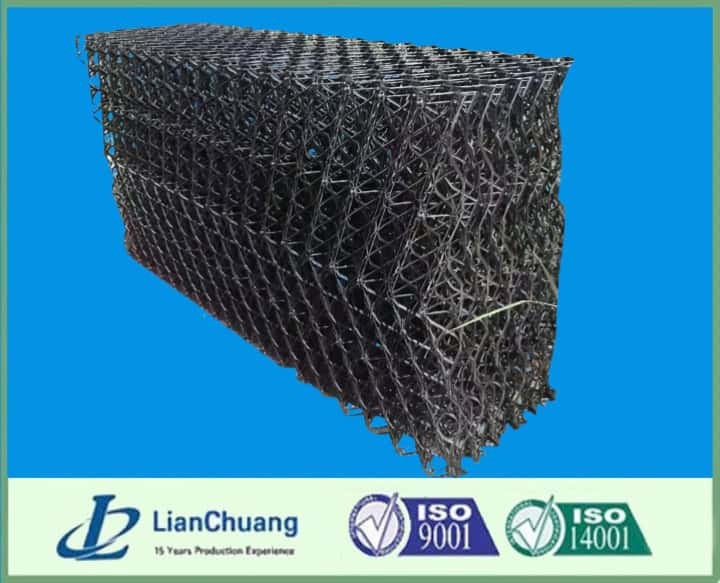

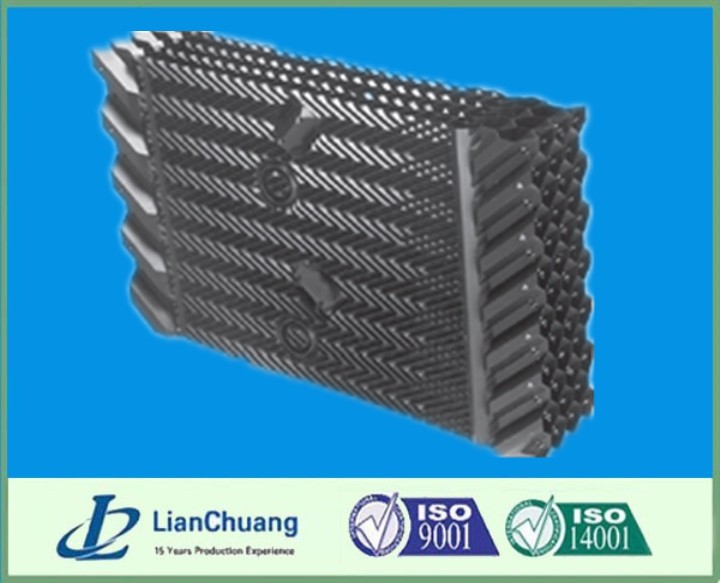

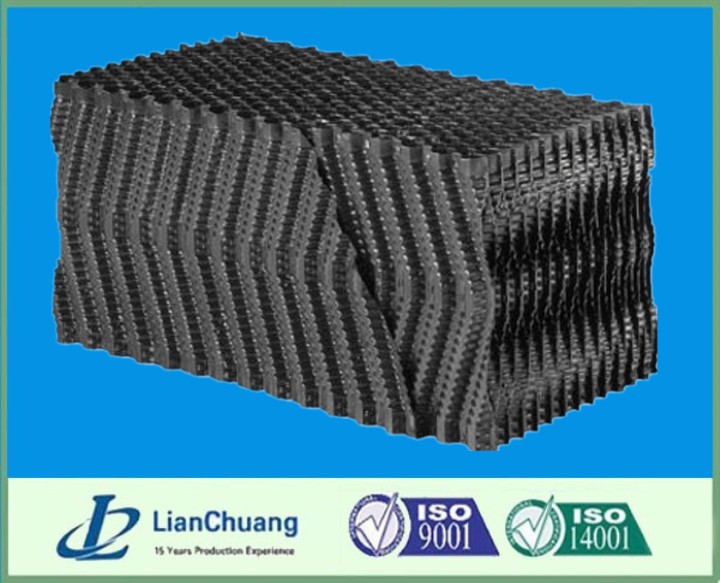

2. Counterflow Fill

Counterflow Fill refers to a design where water and air flow in opposite directions within the fill. Water flows downward while air flows upward. This design increases the contact time between water and air, improving cooling efficiency, but installation and maintenance are relatively complex.

Counterflow Fill refers to a design where water and air flow in opposite directions within the fill. Water flows downward while air flows upward. This design increases the contact time between water and air, improving cooling efficiency, but installation and maintenance are relatively complex.

Features:

- Efficient Cooling: The counterflow design allows for longer contact time between water and air, resulting in more thorough heat exchange and significant cooling effects.

- Structural Design: Typically, counterflow fills have lattice or multi-layer staggered arrangements, increasing the surface area and contact opportunities between water and air.

- Complex Maintenance: Due to the opposite flow directions of water and air, the fill may clog more easily, increasing the difficulty of cleaning and maintenance.

Application Scenarios:

- Small to Medium-sized Cooling Towers: Counterflow fills are often used in small to medium-sized cooling towers, suitable for areas with good water quality and high space requirements.

- High-Efficiency Cooling Needs: Suitable for industrial processes requiring high-efficiency cooling, such as chemical and pharmaceutical industries.

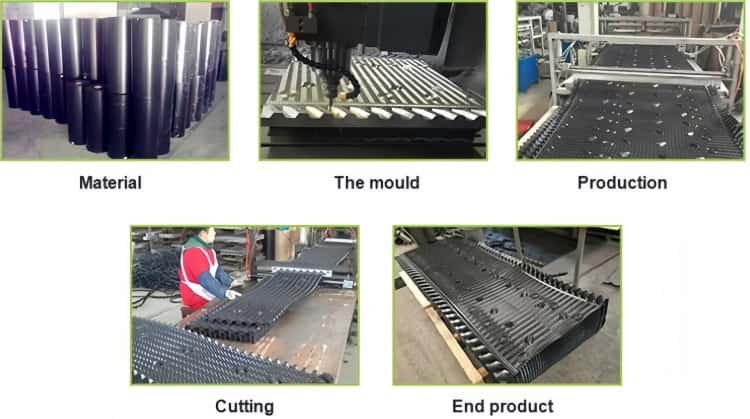

We are dedicated to delivering top-notch quality and ensuring customer satisfaction. Our products are crafted with cutting-edge technology and premium materials, adhering to the highest standards. Rigorous testing guarantees dependable and consistent performance. Our team of specialists is readily available to assist you in selecting the ideal Cooling Tower Fill for your needs and to offer technical support whenever necessary.

Related Link: