Product Description

Submerged Aerobic Fixed Film Reactor (SAFF) Media is an essential component of the SAFF technology, which is a cost-effective solution for wastewater treatment and sewage sanitation, ideal for residential and commercial complexes. SAFF technology encompasses three main stages: Primary Settlement, Secondary Treatment, and Final Settlement/Clarification. And saff media widely recognized for its cost-effectiveness and simplicity in wastewater treatment and sewage sanitation. Primarily used in residential and commercial complexes, SAFF Media plays a crucial role in the three stages of wastewater treatment: Primary Settlement, Secondary Treatment, and Final Settlement/Clarification

In the wastewater industry, SAFF Media is valued for its efficiency, particularly in small to medium-sized treatment plants where land availability is limited, and full-time operational staffing is uneconomical. Designed with no moving parts within the process zones, SAFF Media ensures uninterrupted treatment while allowing easy access to serviceable items. This robust and innovative media enhances the performance of Submerged Aerated Filter plants, making it an ideal choice for effective and reliable wastewater treatment in both residential and commercial settings

Submerged Aerobic Fixed Film Reactor (SAFF) media is a pivotal component in the innovative SAFF technology, designed to provide an efficient and cost-effective solution for wastewater treatment and sewage sanitation in residential and commercial complexes. This cutting-edge media is integral to the three-stage treatment process, which includes Primary Settlement, Secondary Treatment, and Final Settlement/Clarification.SAFF media excels in the wastewater industry as a simple and economical method for treating sewage, especially in small to medium-sized treatment plants where space is limited and full-time operational staffing would be impractical. The media’s design ensures that there are no moving parts within the process zones, minimizing maintenance requirements and maximizing operational efficiency.

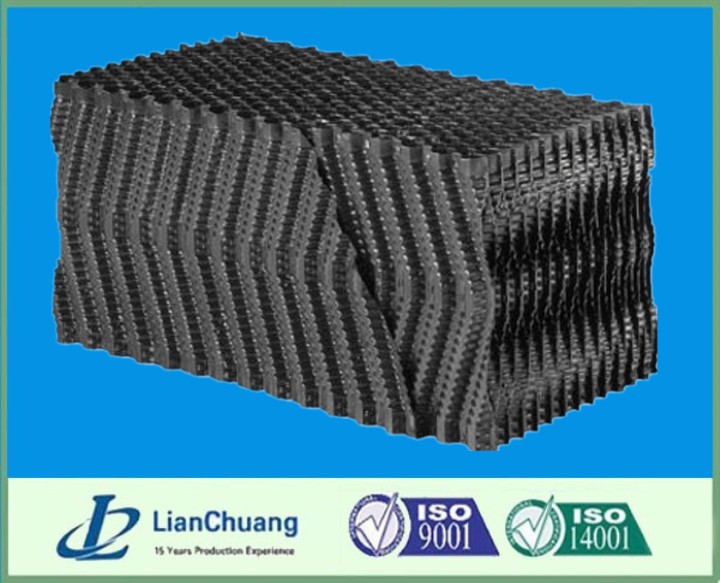

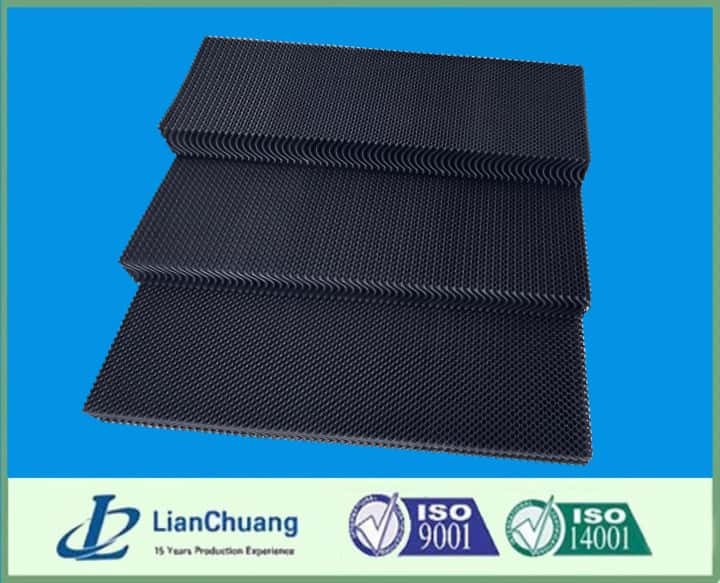

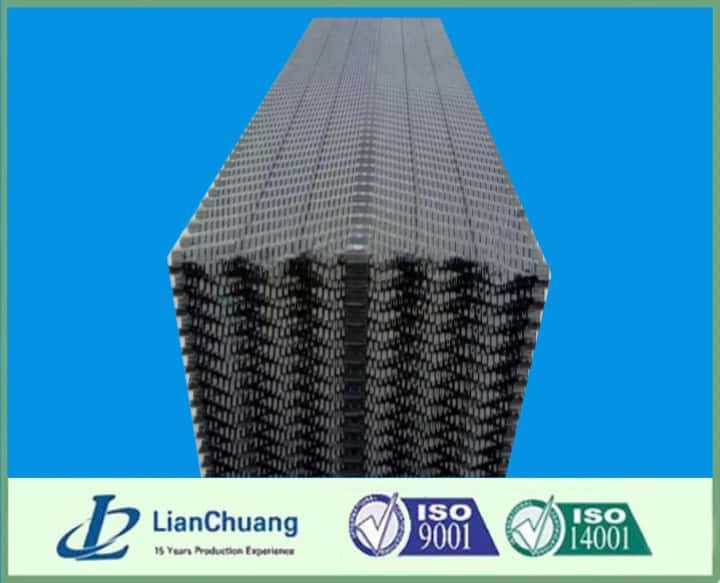

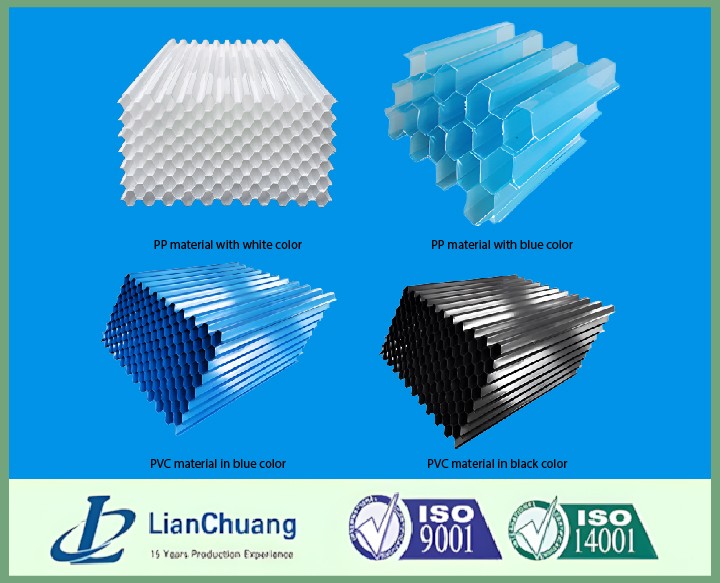

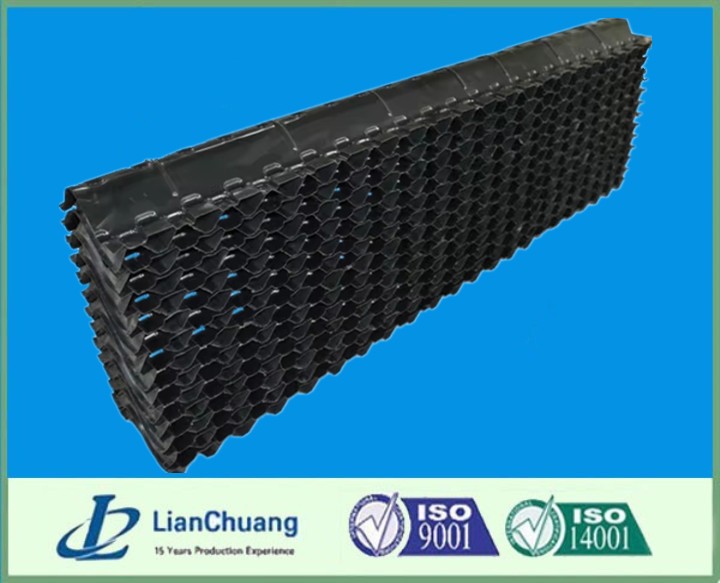

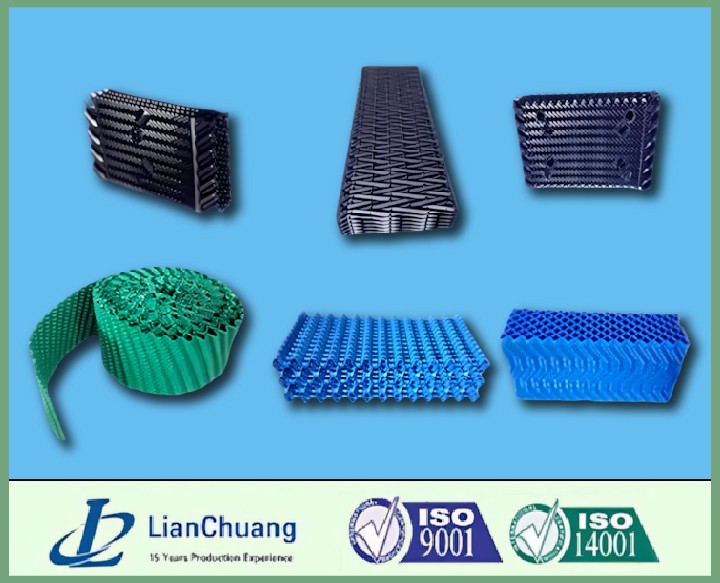

SAFF Media PVC Fill Sheet data:

Material: PVC

With 42% oxygen index.

Material grade: flame spread rate not to exceed 25 per ASTM E-84.

Working temperature: 65 °C to 75 °C.

Tensile strength: 6300 psi. Standard: ISO 9001:2008.

Color: black, blue, transparent or other customized colors.

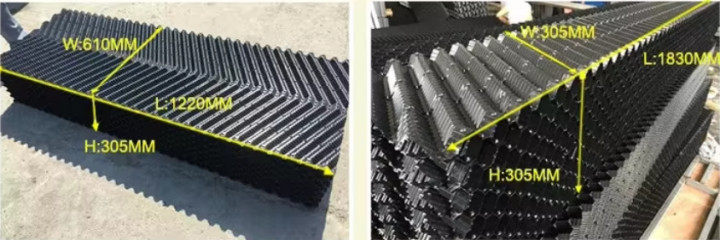

Typical sheet size: as request.

Key features of SAFF media include:

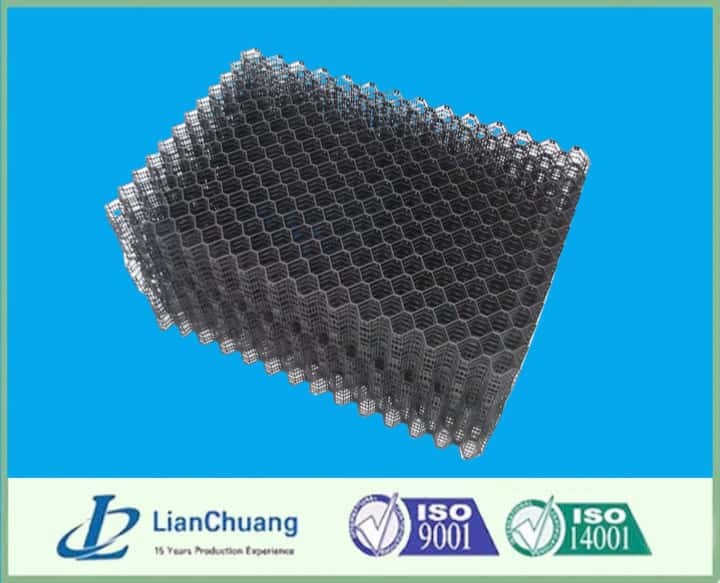

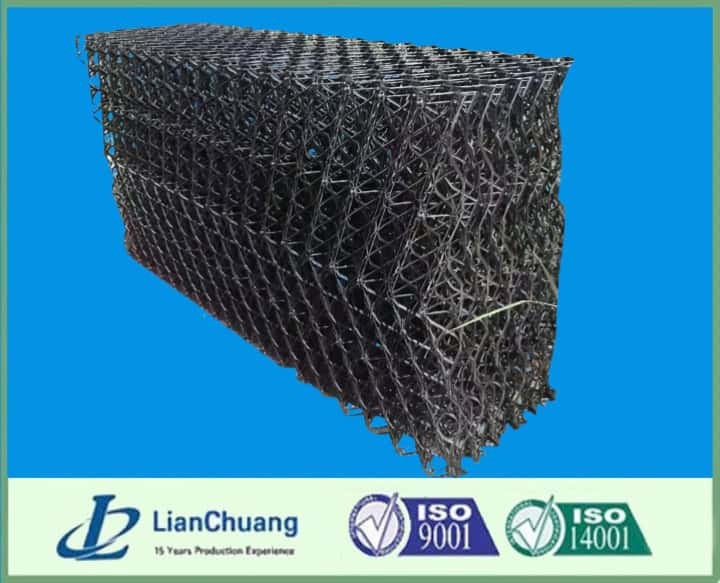

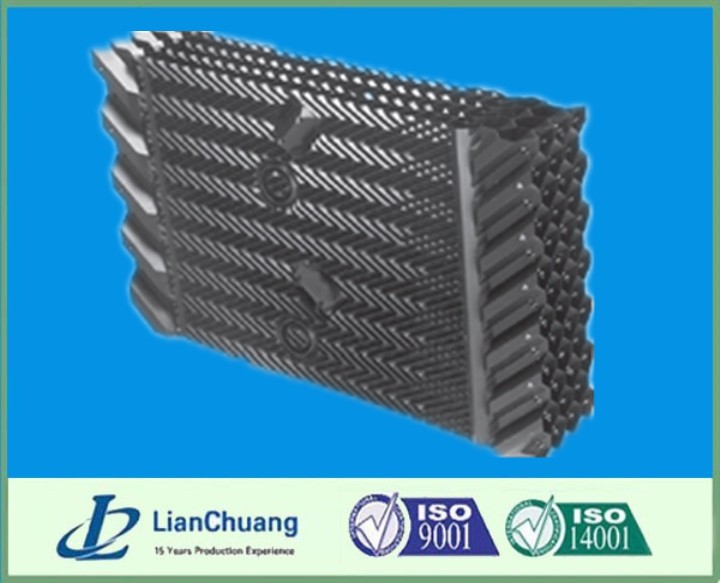

1.High Surface Area: The media offers a large surface area for biofilm growth, enhancing the biological treatment process by providing ample space for microbial colonization.

2.Durability: Made from robust materials, SAFF media is designed to withstand the harsh conditions of wastewater treatment, ensuring long-term performance and reliability.

3.Efficient Transfer: The media facilitates excellent oxygen transfer to the biofilm, promoting aerobic digestion of organic matter and ensuring high treatment efficiency.

4.Light in Weight:The SAFF system is designed with lightweight materials, making the overall structure easy to transport and install. Its lightweight makes it particularly suitable for various environments, especially where quick deployment and flexible adjustments are required.

5.Low Maintenance: With no moving parts within the treatment zones, the SAFF system is easy to maintain, and any serviceable components are strategically positioned for easy access without interrupting the ongoing treatment process.

6.Compact Design: Ideal for installations where land availability is limited, the compact design of SAFF media makes it suitable for both new installations and retrofitting existing treatment plants

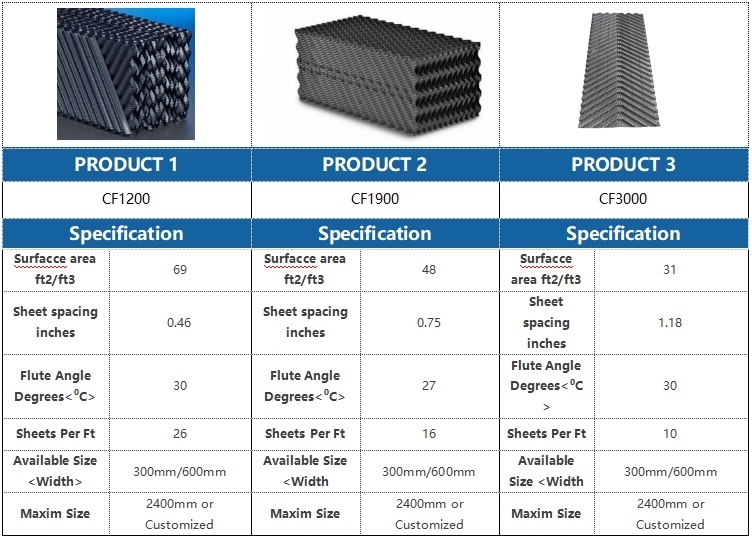

SAFF media specification:

SAFF Media Applications:

Submerged Fixed Film Bed Reactors for Nitrification

Submerged Fixed Film Bed Reactors for Anaerobic Decomposition

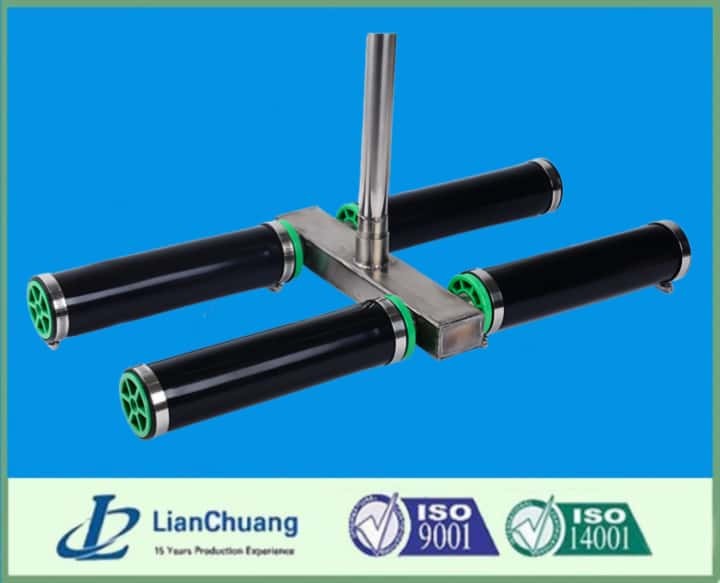

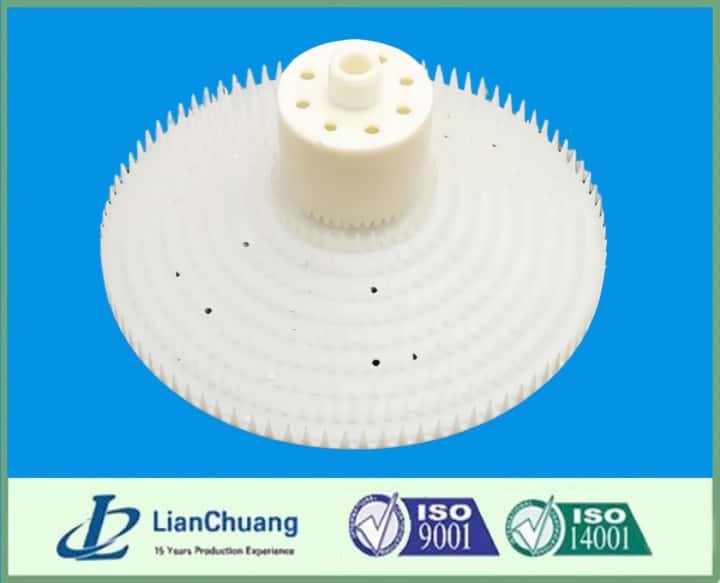

Rotating Biological Contactors for BOD Reduction and Nitrification

Potable Water Conditioning/ Spray Tower for Water De-gasification and Water Aeration

SAFF Media Package: