Product Description

drift eliminators are vital components in cooling towers and other evaporative cooling systems. They are constructed from inert polyvinyl chloride (PVC) plastic material, which effectively eliminates corrosion of these critical components. Drift eliminators are assembled in sections, facilitating easy removal for inspection and maintenance of the water distribution system. They also incorporate UV inhibitors to resist cracking and degradation due to sunlight.

1. Drift Eliminators Working Principle

Cooling tower drift eliminators are improved products that include a resistance tendon, enhancing their ability to avoid the loss of secondary drift. This modification significantly increases the efficiency of drift elimination compared to older models.

2. Drift Eliminator Characteristics:

1.Maximum operational safety.

2.Legal compliance.

3.Maintenance of the original thermal performance of your cooling equipment.

4.Easy cleaning.

5.Minimal drift emission ensuring a dry surrounding area.

3. Drift Eliminator Advantages:

1. Reduced environmental impact.

2. Elimination of water droplet issues.

3. No water droplets escape from the system.

4. Water recovery.

5. Energy saving.

6. Increased capture of droplets in collection areas.

7. Very low head losses.

8. High mechanical resistance thanks to the PVC material.

9. Easy maintenance.

10. Resistant to almost all chemical and biological agents.

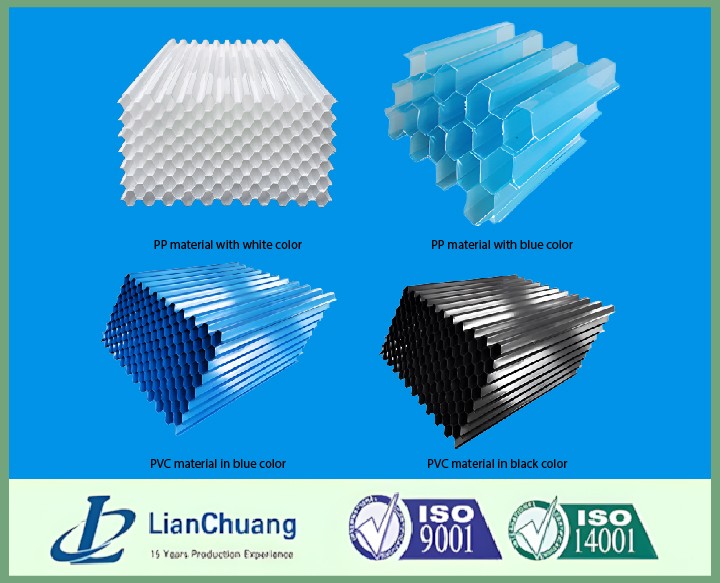

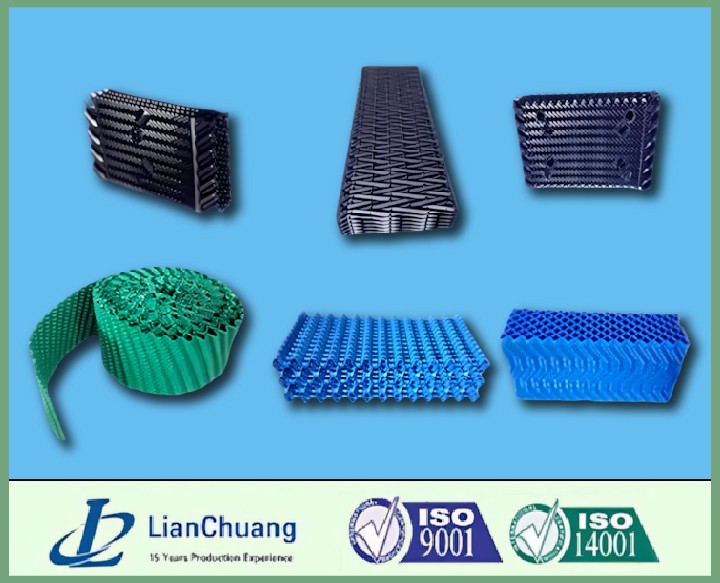

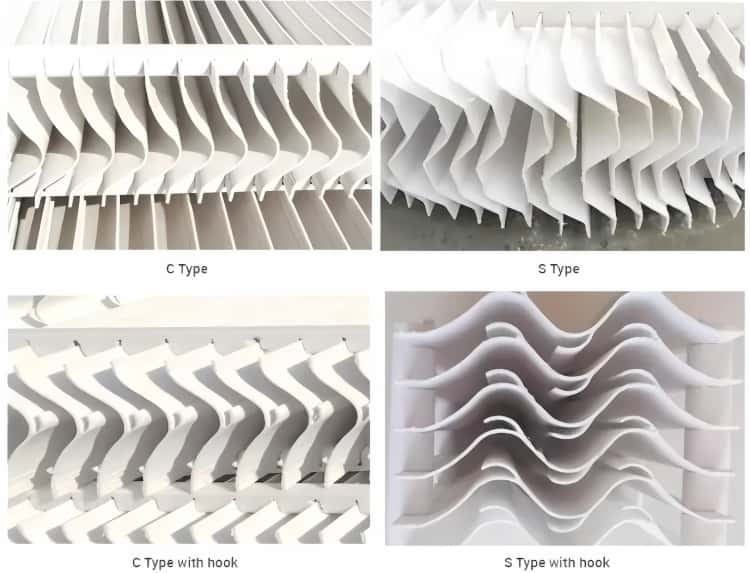

4. Types of Drift Eliminators

Drift eliminators significantly reduce the number of water droplets expelled from cooling towers, conserving water and minimizing environmental impact. There are various types, each designed for specific applications and performance criteria. Here, we explore several types of drift eliminators:

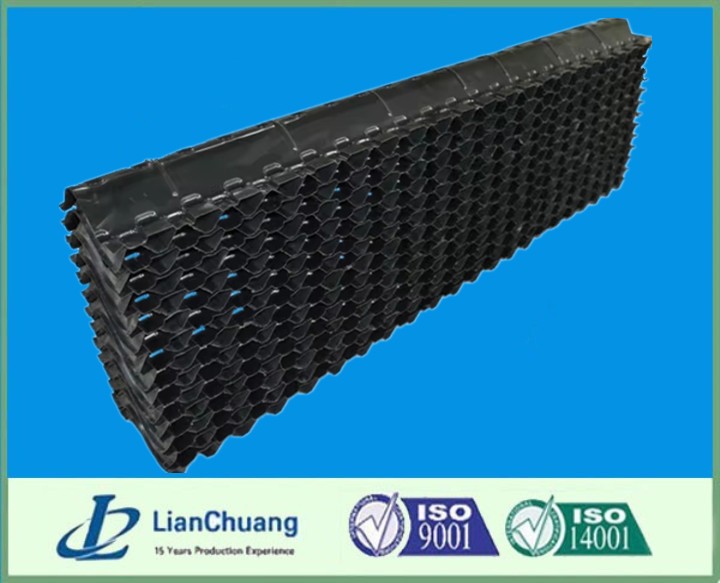

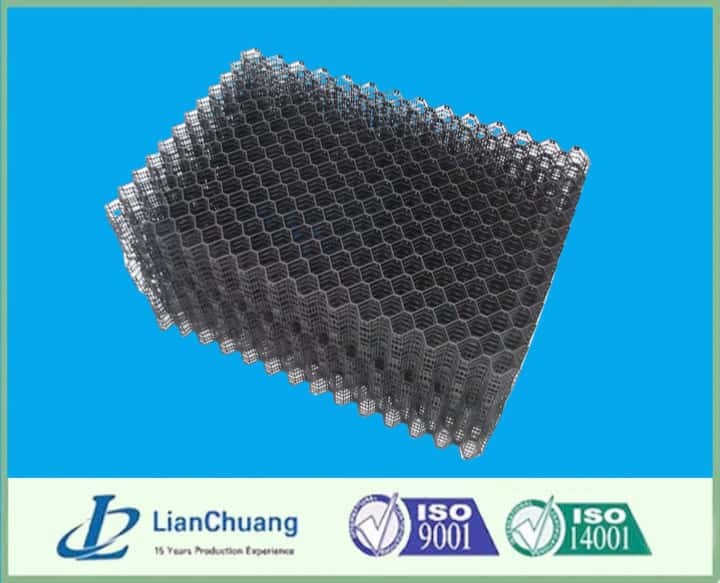

4.1. Cellular Drift Eliminators

Cellular drift eliminators feature a honeycomb-like structure made up of numerous small cells. These cells are angled to continuously change the direction of airflow, effectively capturing and separating water droplets

Characteristics:

High Efficiency: The complex structure effectively captures tiny water droplets, minimizing drift emissions.

Low Airflow Resistance: Optimized design ensures efficient droplet capture while maintaining low airflow resistance.

Durability: Made from materials like PVC and PP, offering excellent corrosion resistance and long lifespan

Applications:

Ideal for cooling towers in industries requiring high-efficiency droplet capture, such as power generation and petrochemicals.

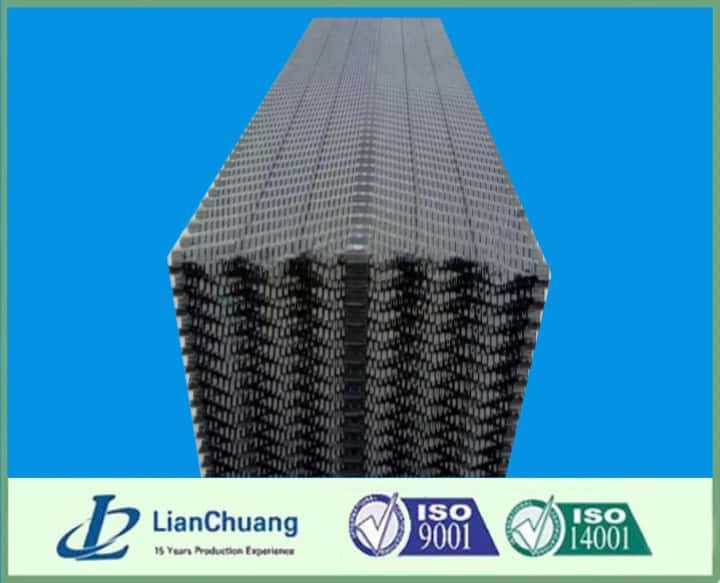

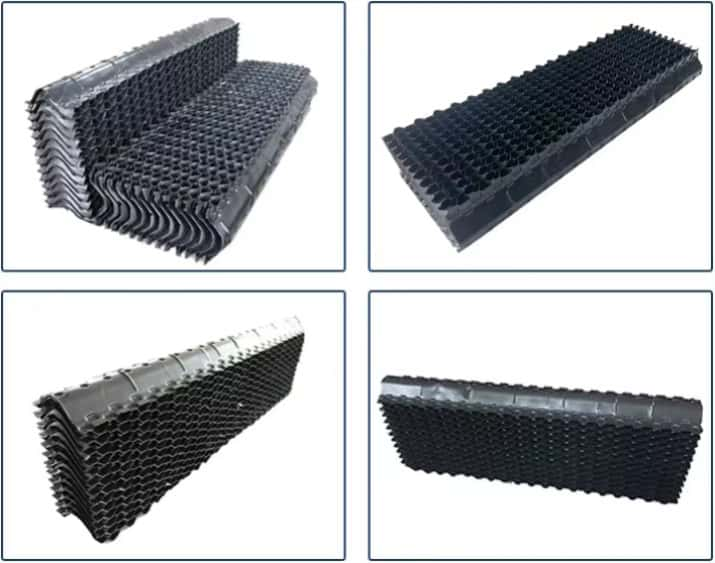

4.2. Blade Drift Eliminators

Blade drift eliminators consist of multiple parallel blades arranged at specific angles to alter airflow direction and capture water droplets

Characteristics:

Simple Structure: The straightforward design allows easy manufacturing and installation.

Effective Separation: The angled blades efficiently capture and separate water droplets.

Easy Maintenance: The simple structure facilitates convenient maintenance and cleaning

Applications:

Widely used in various industrial cooling towers, particularly where low airflow resistance is less critical.

4.3. S-Shape Drift Eliminators

S-Shape drift eliminators have an S-shaped curve, causing the airflow to change direction multiple times, effectively capturing water droplets

Characteristics:

Enhanced Droplet Capture: The multiple directional changes improve droplet separation.

Suitable for High Turbulence: Effective in cooling towers where airflow turbulence is significant

Applications:

Suitable for applications requiring robust droplet capture under varying airflow conditions.

4.4. V-Shape Drift Eliminators

V-Shape drift eliminators feature a V-shaped design, extending the airflow path and enhancing droplet separation efficiency

Characteristics:

Extended Airflow Path: The V-shape design increases the distance droplets travel, improving separation.

Compact Design: Suitable for smaller cooling towers and specific applications

Applications:

Often used in small-scale cooling towers and specialized industrial applications.

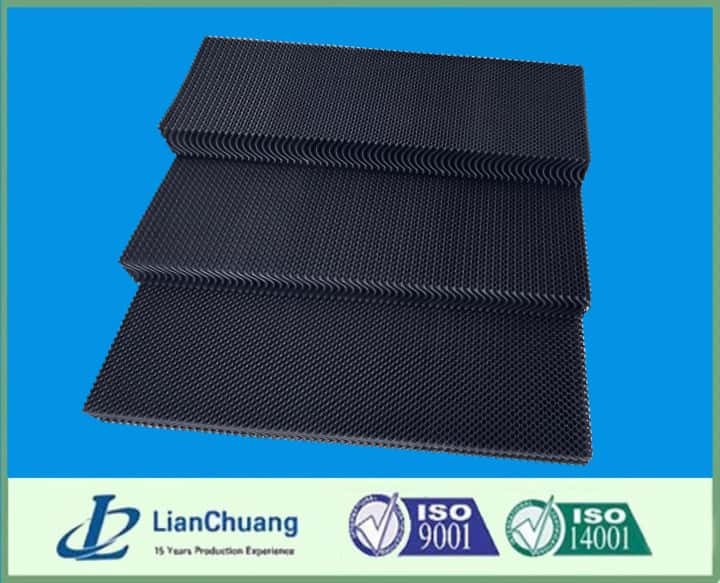

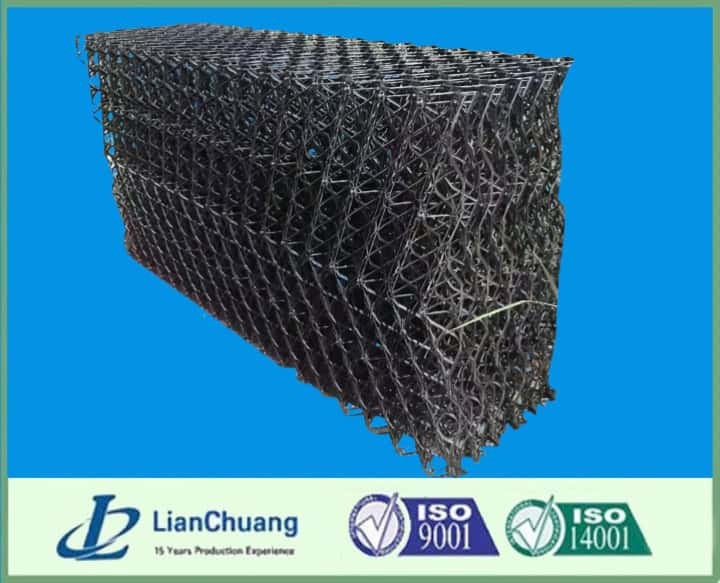

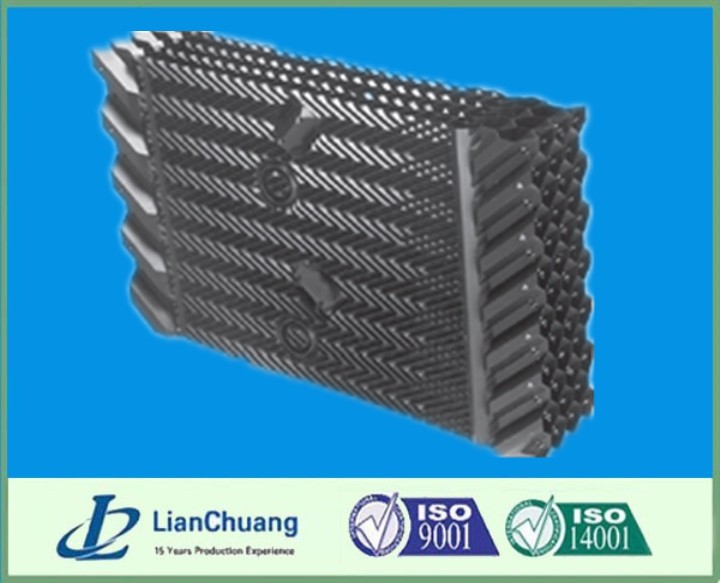

4.5. Chevron Drift Eliminators

Chevron drift eliminators, also known as wave drift eliminators, have a wavy structure that forces the airflow to change direction multiple times

Characteristics:

High Separation Efficiency: The wave-like structure increases the likelihood of droplet capture.

Moderate Airflow Resistance: Balances efficient droplet capture with maintaining reasonable airflow resistance

Applications:

Used in various industrial cooling towers where a balance between efficiency and airflow resistance is needed.

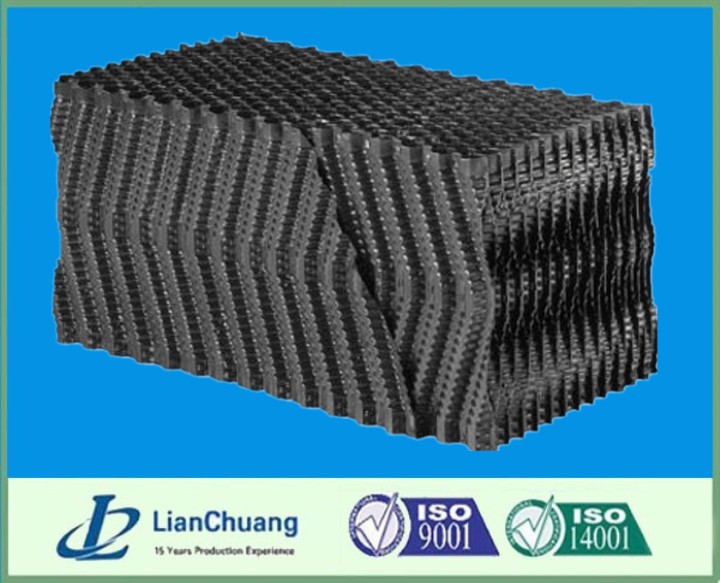

4.6. Tri-Pass Drift Eliminators

Tri-pass drift eliminators force the airflow to change direction three times, significantly increasing droplet capture efficiency

Characteristics:

Triple Direction Change: The three directional changes maximize droplet capture.

High Efficiency: Particularly effective in high-performance cooling tower applications

Applications:

Ideal for high-efficiency cooling towers in industries with stringent water conservation requirements.

Conclusion

Drift eliminators are crucial in reducing water droplet emissions from cooling towers, conserving water, and minimizing environmental impact. The choice of drift eliminator type depends on specific application needs, with options ranging from cellular and blade designs to more specialized S-shape, V-shape, Chevron, and Tri-pass configurations. Each type offers distinct advantages, ensuring that there is a suitable solution for every industrial requirement. By selecting the appropriate drift eliminator, industries can achieve maximum operational safety, legal compliance, and energy savings, while also contributing to environmental sustainability.

Our drift eliminators are engineered for optimal drift removal across all types of evaporative cooling systems, including brands like BAC, Evapco, Aqua Cool, Superchill, Sulzer, and others. For any purchasing needs or questions about Drift Eliminator selection, please reach out to us for an in-depth discussion.