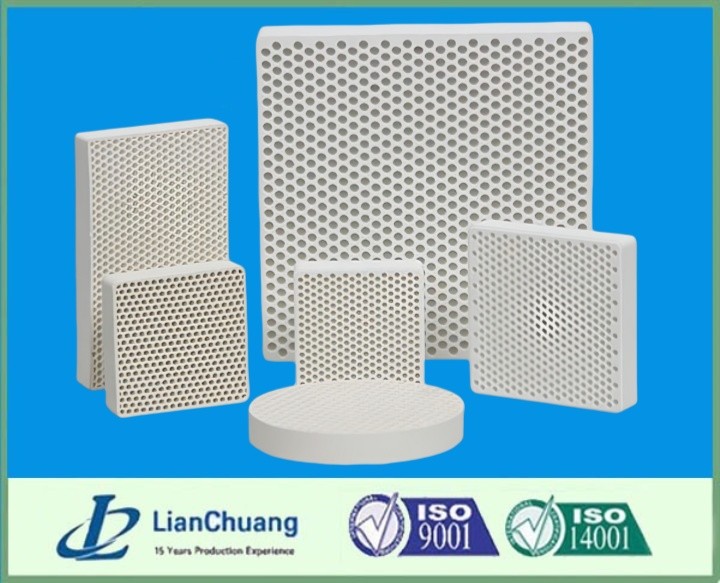

Product Description

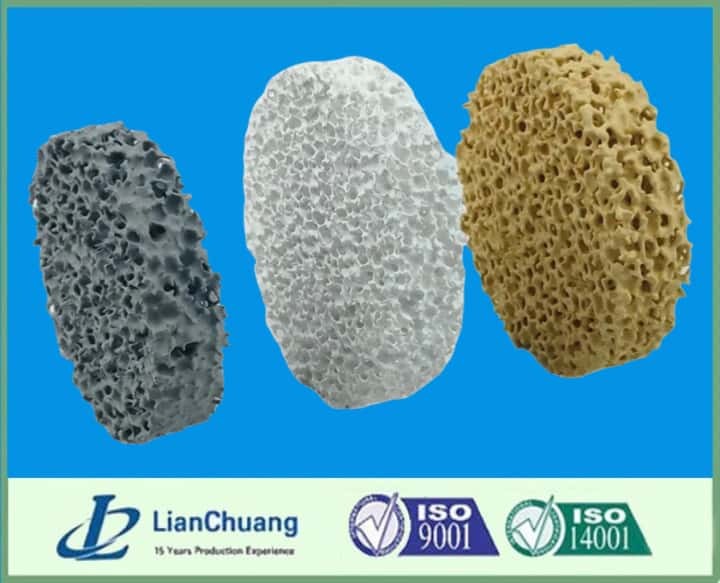

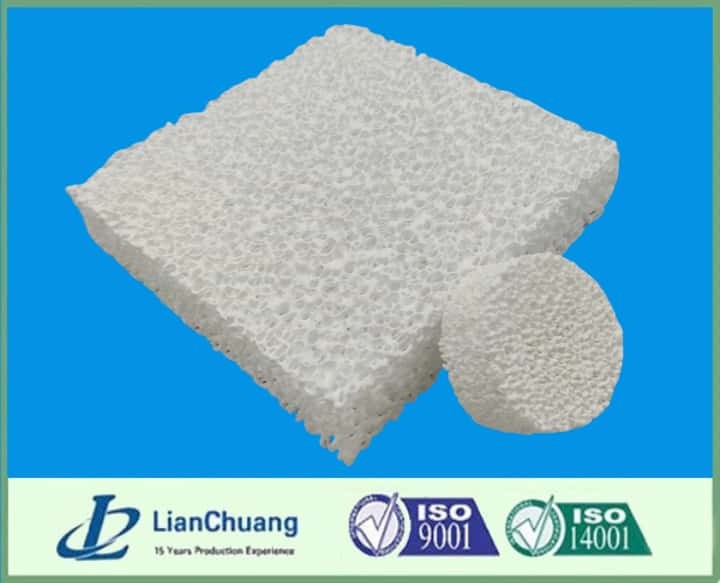

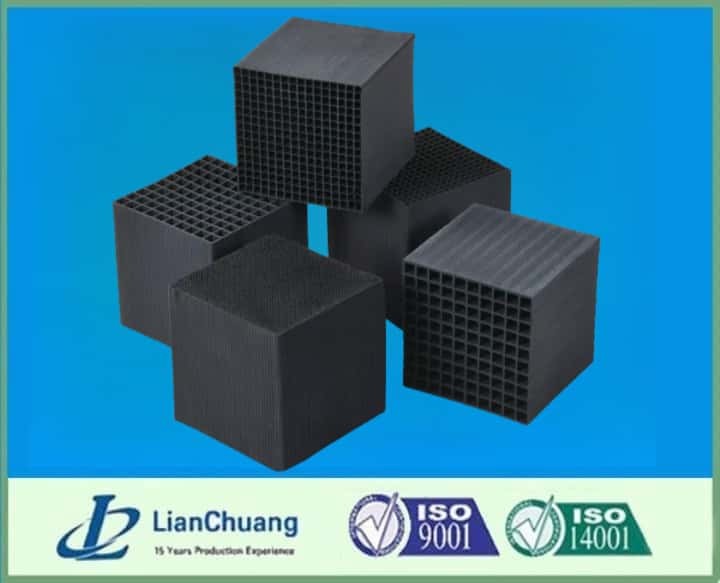

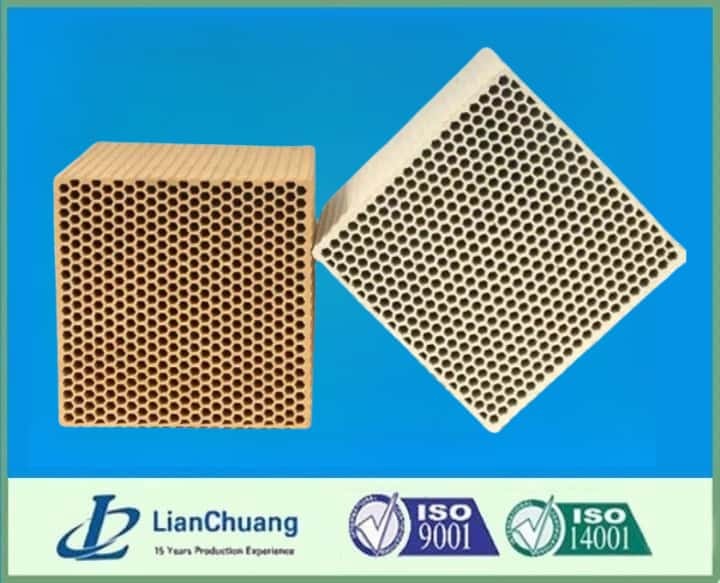

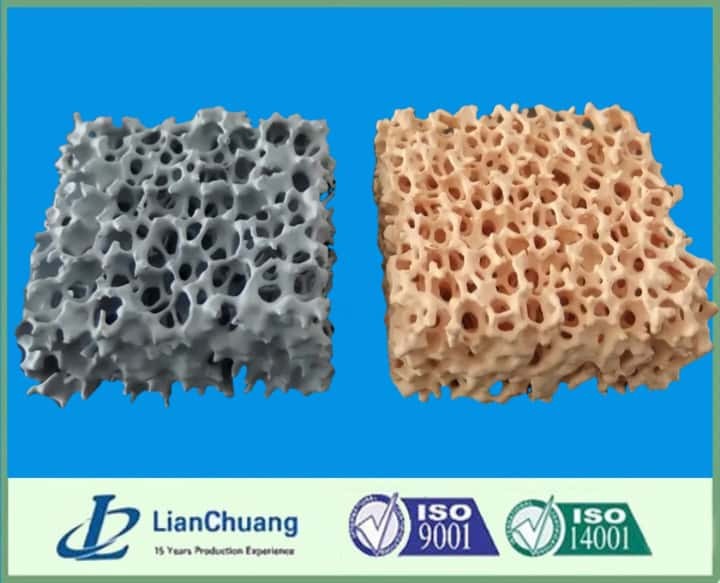

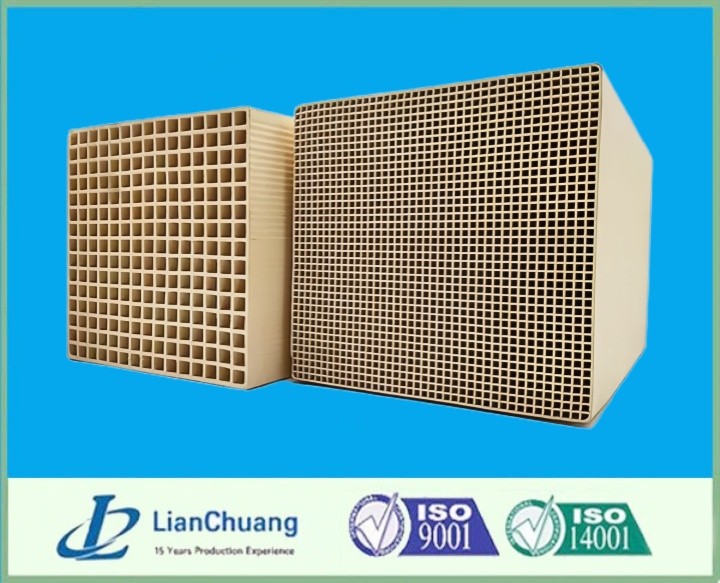

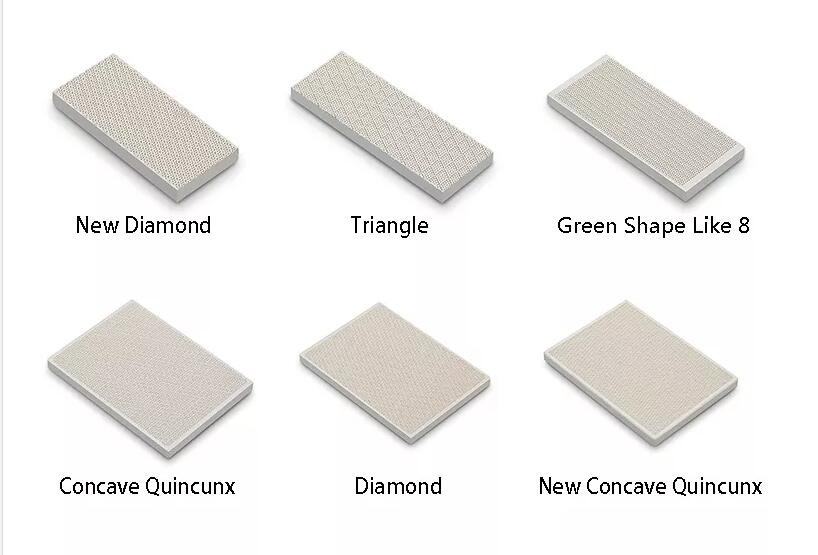

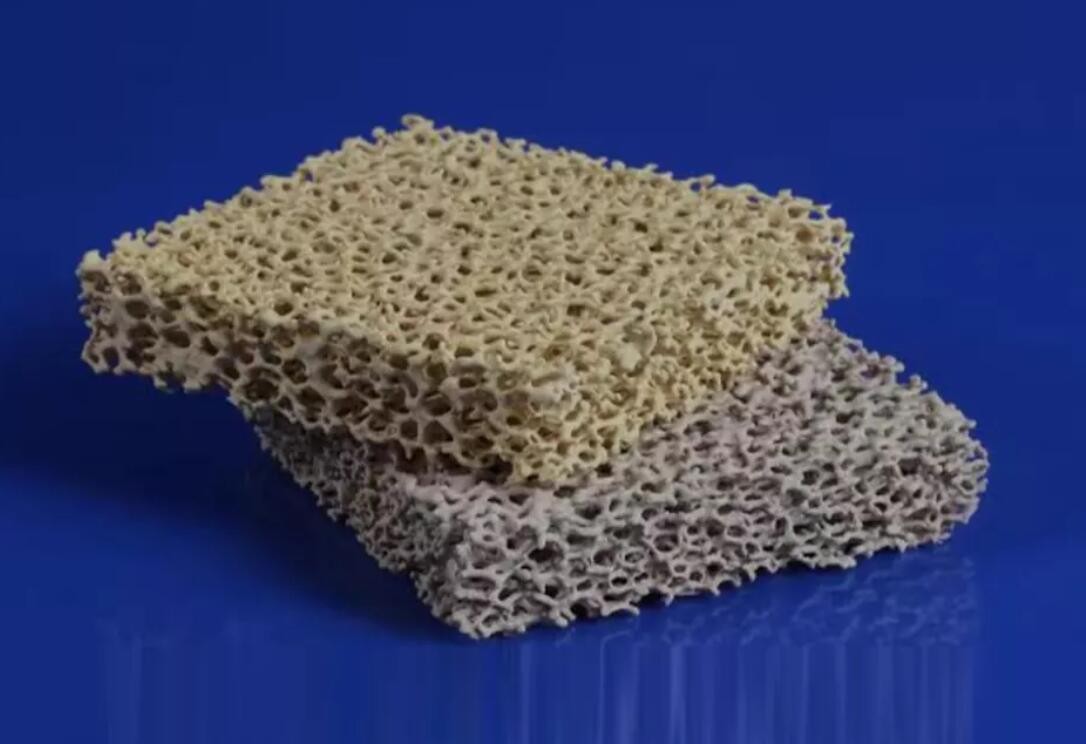

Aluminum Oxide Ceramic Foam Filter is a specialized filtration technology widely used in metal casting applications. Available in both round and square shapes, it features a honeycomb structure designed to maximize filtration performance. This aluminum ceramic foam filter possesses a foam-like, porous structure that offers exceptional attributes such as lightweight design, high chemical stability, large surface area, excellent corrosion resistance, and high mechanical strength, along with impressive thermal shock resistance.

Key Features of Aluminum Ceramic Foam Filter:

- High Porosity: Ensures efficient filtration with minimal resistance.

- Superior Dimensional Accuracy: Consistent and reliable size and shape for effective application.

- Low Thermal Shock Loss: Capable of handling temperature changes without compromising integrity.

- High Mechanical Strength: Maintains structural integrity under both normal and high temperatures.

- Large Surface Area: Offers enhanced filtration efficiency.

- Chemical Stability: Resists degradation from chemical reactions in harsh environments.

- Exceptional Filtering Functionality: Removes impurities and enhances metal quality.

- Efficient Residue Collection and Absorption: Collects residual particles effectively during filtration.

- Beveled Edges and Compressible Gasket: Reduces tool wear and ensures a tight seal for maximum filtration.

Material Specifications:

| Material Types | Alumina (Al₂O₃) | Silicon Carbide | Zirconia |

|---|---|---|---|

| Color Options | White | Grey Black | Yellow |

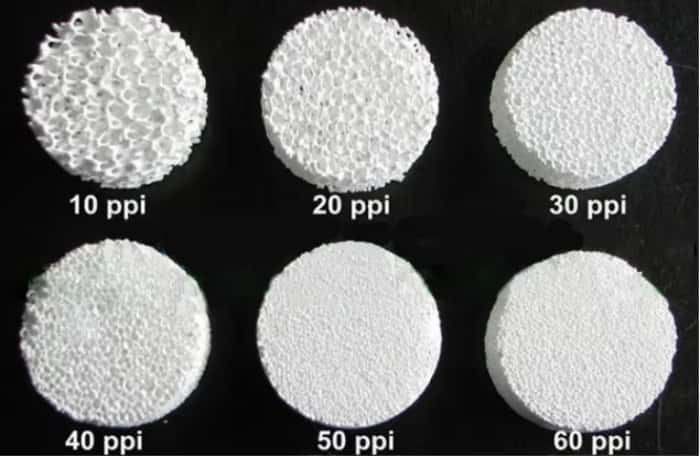

| Pore Density | 10-60 PPI | 10-60 PPI | 10-60 PPI |

| Porosity | 80-90% | 80-90% | 80-90% |

| Refractoriness | ≤1100ºC | ≤1500ºC | ≤1700ºC |

| Bending Strength | >0.6 MPa | >0.8 MPa | >1.0 MPa |

| Compression Strength | >0.8 MPa | >0.9 MPa | >1.2 MPa |

| Volume Weight | 0.3-0.45 g/cm³ | 0.35-0.5 g/cm³ | 0.9-1.5 g/cm³ |

| Thermal Shock Resistance | 6 times at 1100ºC | 6 times at 1100ºC | 6 times at 1100ºC |

Filter Dimensions and Capacities:

| Dimensions (mm) | Pouring Rate (kg/s) | Filtration Capacity (tons) | Application |

|---|---|---|---|

| 40x40x22 | 4 | 65 (Grey Iron), 32 (Ductile Iron) | Aluminum, Alloys |

| 50x50x22 | 6 | 100 (Grey Iron), 52 (Ductile Iron) | Aluminum, Alloys |

| 75x50x22 | 9 | 150 (Grey Iron), 75 (Ductile Iron) | Aluminum, Alloys |

| 75x75x22 | 14 | 220 (Grey Iron), 100 (Ductile Iron) | Aluminum, Alloys |

| 100x50x22 | 12 | 200 (Grey Iron), 100 (Ductile Iron) | Aluminum, Alloys |

| 100x75x22 | 18 | 300 (Grey Iron), 150 (Ductile Iron) | Aluminum, Alloys |

The Aluminum Oxide ceramic foam filter is an essential component for enhancing the quality of castings, particularly in aluminum and metal alloy industries. With its advanced filtration capabilities, high resistance to thermal shock, and durability, this filter is the go-to solution for applications requiring precise metal purification. By effectively removing impurities, it improves casting quality, reduces defects, and ensures a higher yield for manufacturers.