Product Description

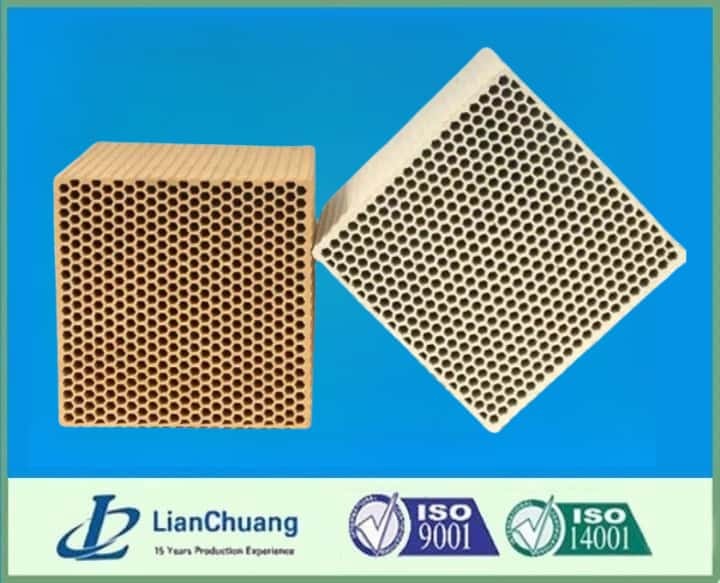

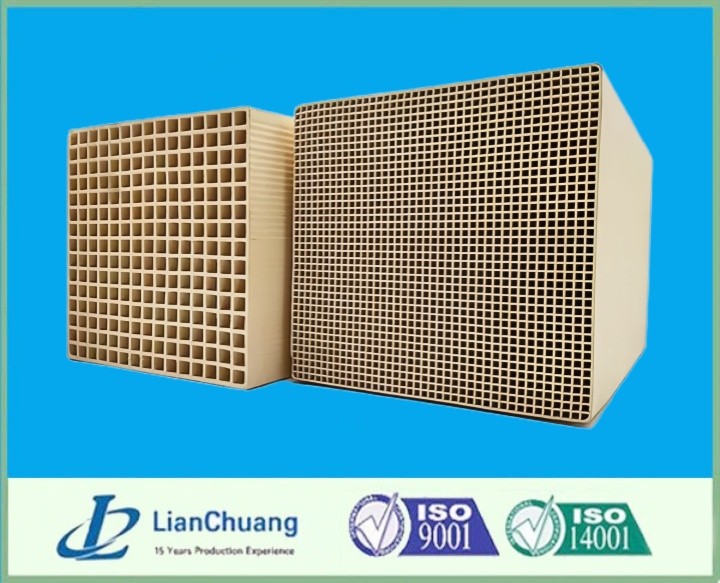

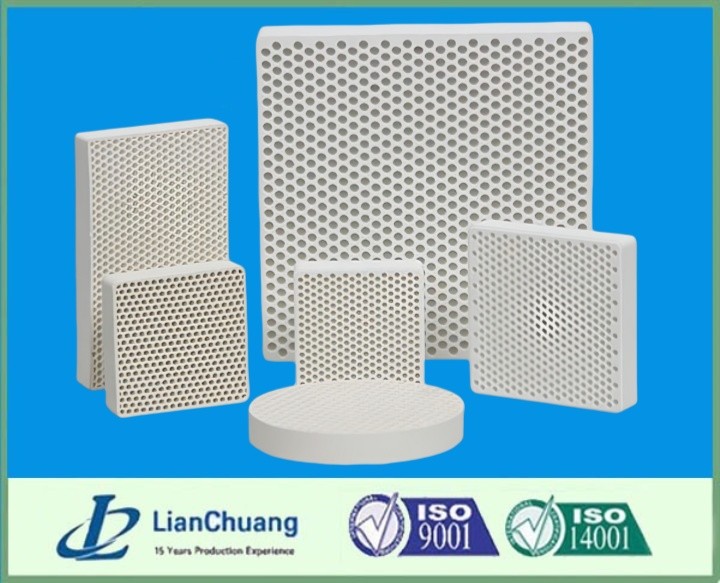

Infrared Ceramic Honeycomb Plate used in combustion oven, using modern advanced science and technology and selecting high-purity and high-quality cordierite. They have the advantages of high heat efficiency and low energy consuming, low pollution, economical and practical, easy installing, high ventilative rate and strong heat radiation, etc. Compared with the electrical drying stove and common gas-fired combustion stove, infrared honeycomb ceramic plates have the following advantages:

1.Save 30~50% energy consumption.

2.Burn without flame, low noise.

3.Reduce the formulation of such harmful gas as CO, NOx, etc by a large margin (more than 70%)

4.Strong bearing of wind, using safely.

5.Uniform radiant burning

6.good resistance against mechanical and thermal shock under normal operating conditions.

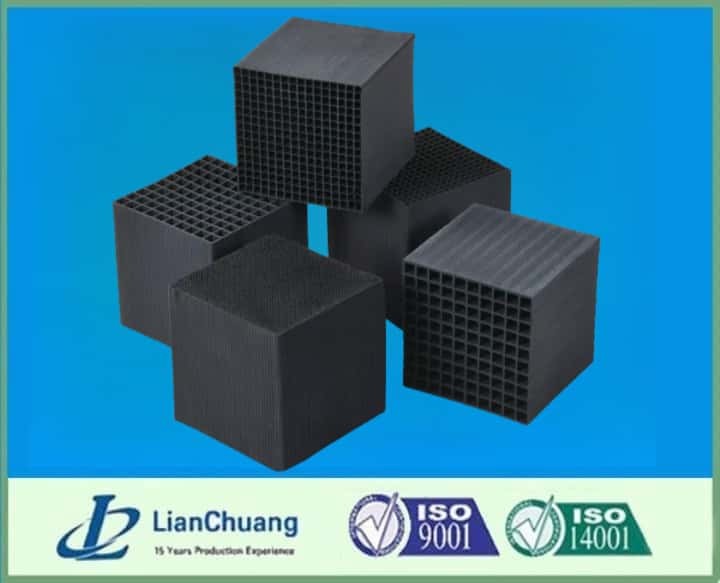

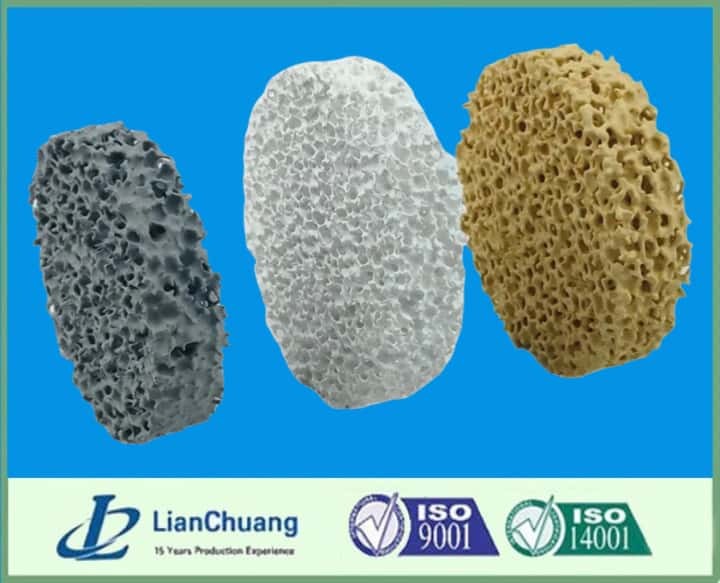

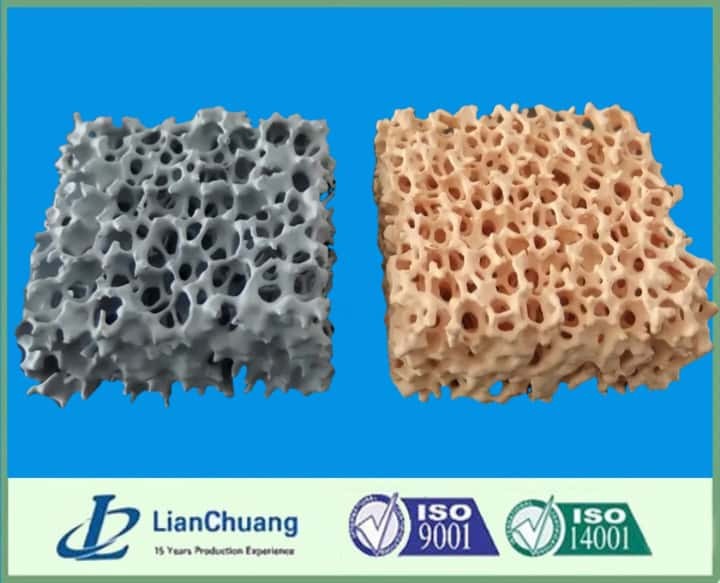

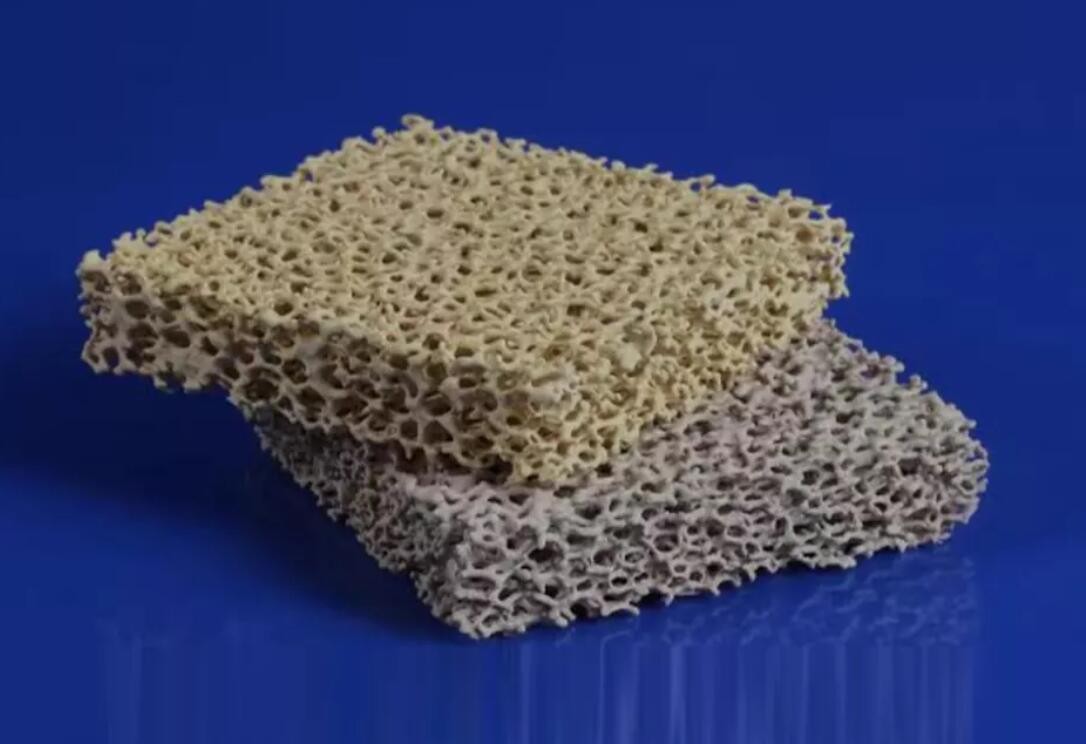

Material:Honeycomb ceramics can be made from a variety of materials. The main materials are: cordierite, mullite, aluminum titanate, activated carbon, silicon carbide, activated alumina, zirconia, silicon nitride and cordierite-mullite, cordierite-aluminum titanate and other composite substrates.

Properties:Environmentally friendly ceramics Ceramic materials can be widely used in various environmental protection fields due to their high strength, high temperature resistance, corrosion resistance and wear resistance, such as automobile exhaust emissions. As a filter material, honeycomb ceramic has the following advantages: good chemical stability, acid and alkali resistance and organic solvent; excellent resistance to rapid heat and rapid cooling, working temperature up to 1000 ° C; good antibacterial property, not easy to be degraded by bacteria, not easy to block and easy Regeneration; strong structural stability, narrow pore size distribution, high permeability; non-toxic, especially suitable for food and drug treatment.

Application: the kitchen burning gas, gas water heater, burn oven, industrial baking equipment, industrial organic waste gas combustion, cabinet heaters, etc.

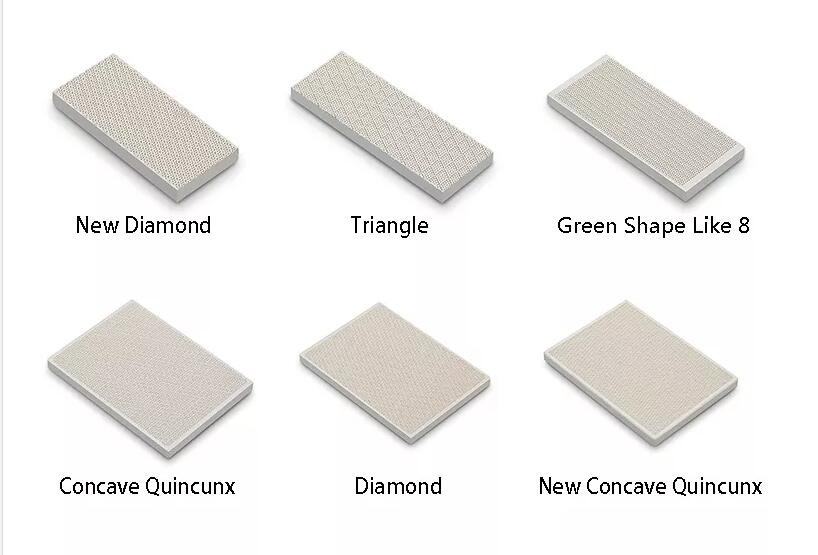

Specification:

TYPE | SIZE(lengh * width mm) | HOLE QUANTITY | HOLE SHAPE | HOLE SIZE(mm) |

1 | 100*150 | 24*36 | SQUARE | 3 |

2 | 150*100 | 35*20 | HEXAGON | 3.6 |

3 | 150*100 | 30*23 | SQUARE | 4 |

4 | 150*100 | 23*13 | HEXAGON | 6 |

5 | 150*100 | 36*24 | SQUARE | 3 |

6 | 150*100 | 13*10 | HEXAGON | 9 |

7 | 100*100 | 22*25 | HEXAGON | 3.6 |

8 | 100*100 | 8*10 | HEXAGON | 9 |

9 | 100*100 | 13*15 | HEXAGON | 6 |

10 | 100*100 | 6*7 | HEXAGON | 12 |

11 | 100*100 | 18*18 | HEXAGON | 3.6 |

12 | 100*100 | 19*19 | SQUARE | 3.6 |

13 | 250*250 | 46*53 | ROUND | 4.1 |

14 | 250*200 | 53*37 | ROUND | 4.5 |

15 | 50*50 | 28*28 | SQUARE | 1.3 |

16 | 126*94.5 | 10*9 | HEXAGON | 9 |

17 | 150*150 | 43*43 | SQUARE | 2.6 |

18 | 150*150 | 25*25 | SQUARE | 4.8 |

19 | 150*150 | 4*4 | HEXAGON | 34 |

20 | 153.8*153.8 | 100*100 | SQUARE | 1 |

21 | 120*120 | 38*38 | SQUARE | 2.5 |