Product Description

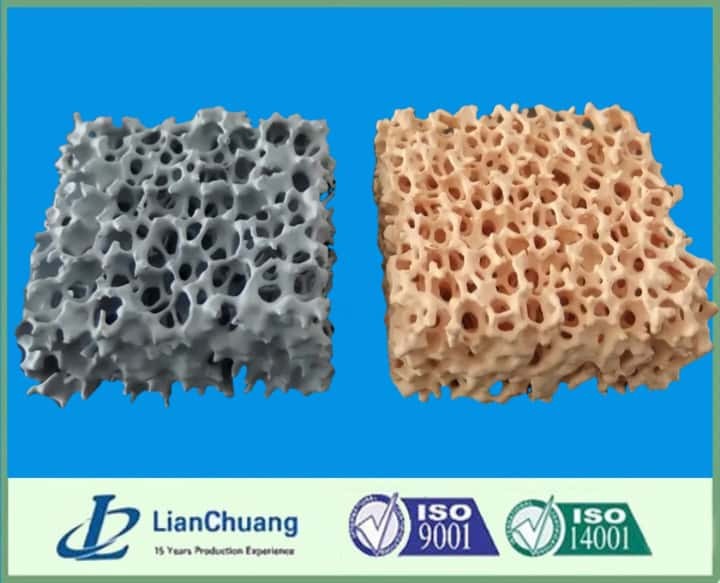

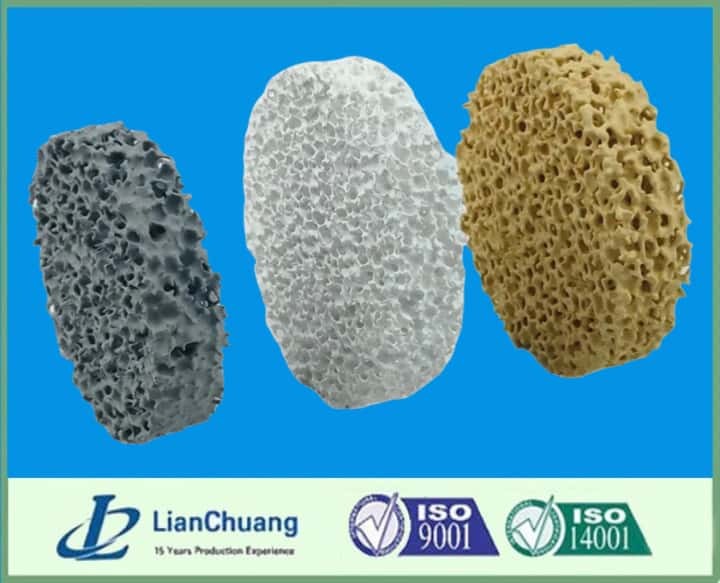

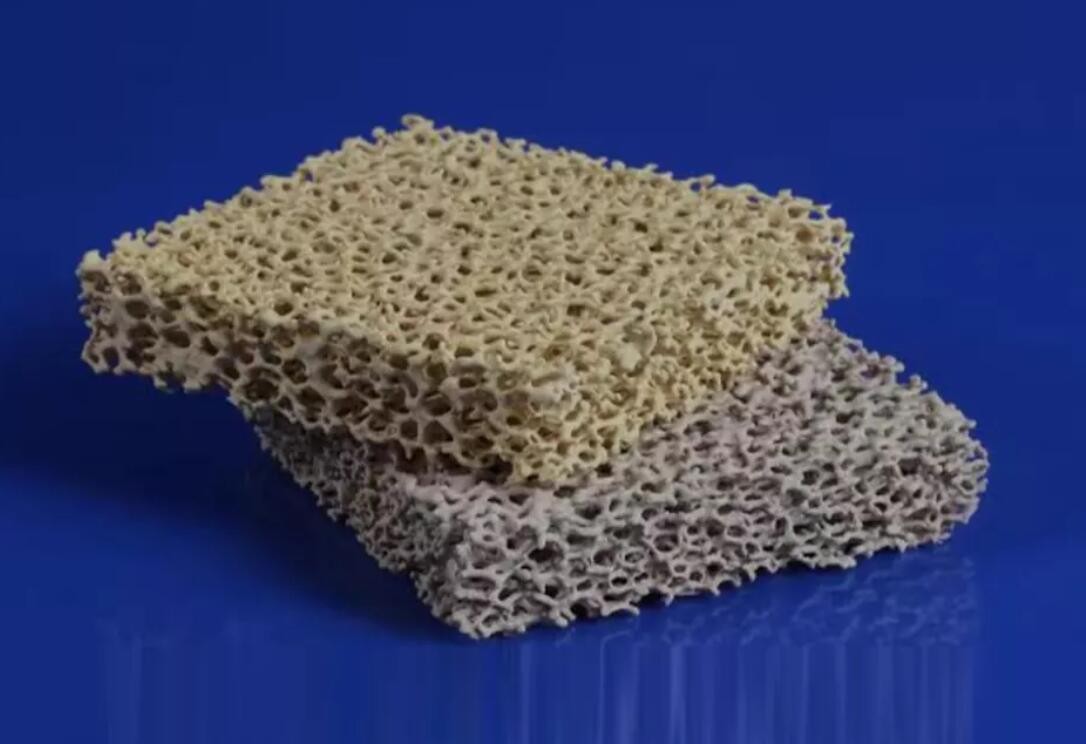

Magnesia Ceramic Foam Filters are specially designed for the filtration of magnesium alloys. With their exceptional resistance to molten metal attacks and corrosion, these filters effectively remove inclusions and reduce trapped gases from molten metal. The magnesia ceramic foam filter provide a laminar flow, resulting in significantly cleaner metal that enhances the quality of castings. Cleaner metal leads to fewer defects, reduced scrap, and a higher yield, all of which contribute directly to increased profits for your casting operations.

Key Features of Magnesia Ceramic Foam Filter:

- Effective Filtration: These magnesia ceramic foam filter s efficiently remove inclusions and trapped gases, ensuring a cleaner and higher-quality metal.

- Enhanced Castings: Cleaner metal results in fewer defects, higher casting quality, and reduced scrap and welding repair rates.

- Improved Surface Quality: The filtration process enhances the surface finish of the castings, making them smoother, shinier, and more durable.

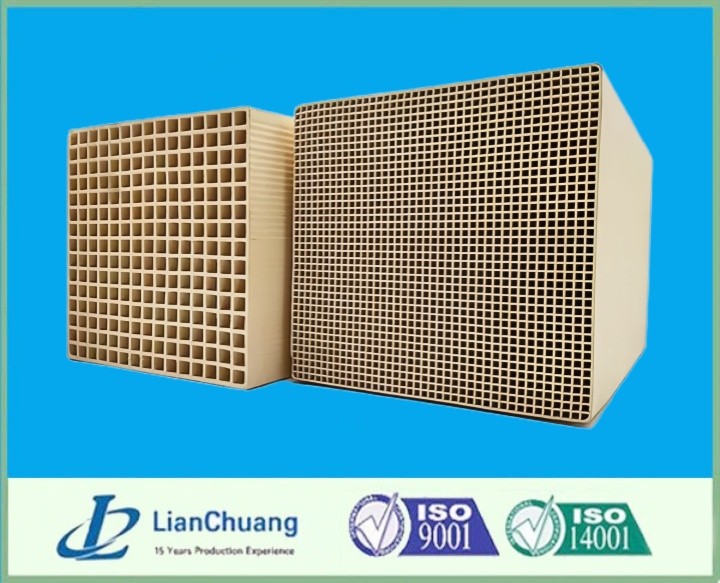

- Optimized Flow Control: The filters regulate the flow rate of molten metal through rectification, contributing to more efficient casting and reduced blowhole formation.

Product Benefits:

- Reduced Inclusions: By filtering out solid impurities such as slag, sand, and oxides, our magnesia ceramic foam filters ensure that only pure and high-quality magnesium alloy is used for casting.

- Improved Mechanical Properties: The filtering process improves the mechanical properties of cast products, making them more durable and resilient.

- Enhanced Productivity: A cleaner casting process reduces defects, increases the yield of high-quality castings, and improves overall productivity.

- Superior Heat and Chemical Resistance: Made from 99% magnesium oxide (MgO), these filters are designed to withstand high temperatures (up to 1200°C) and are resistant to the aggressive chemical properties of molten magnesium alloy.

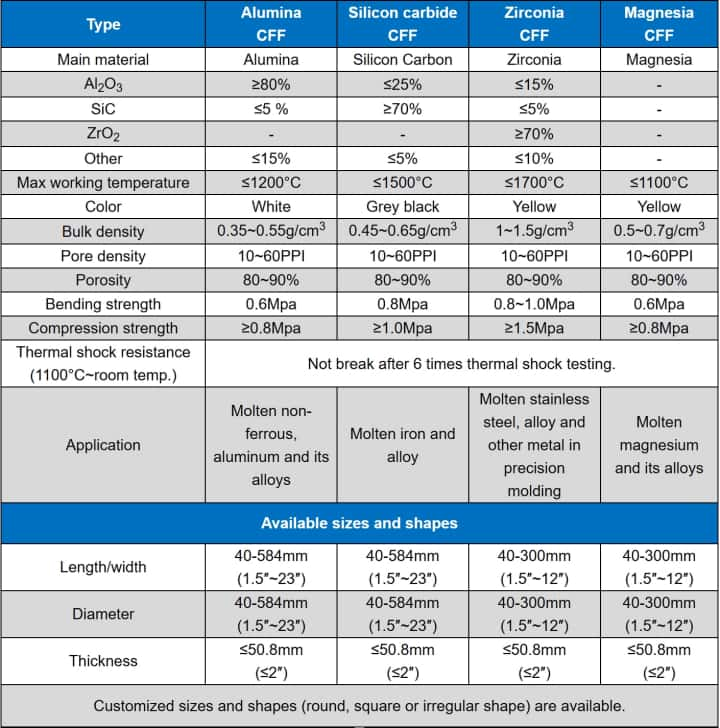

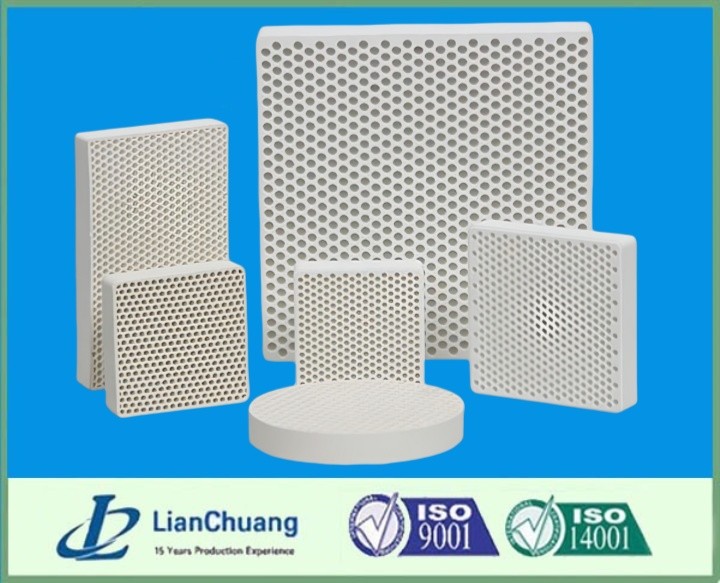

Magnesia Ceramic Foam Filter Technical Parameters:

| Item | Unit | Technical Index |

|---|---|---|

| Main Raw Material | MgO | |

| Pore Density | PPI | 8-60 |

| Porosity | % | 80-90% |

| Operating Temperature | °C | ≥1100 |

| Bending Strength | MPa | ≥0.8 |

| Compression Strength | MPa | ≥0.9 |

| Thermal Shock Resistance | 1100°C, water cooling, cycles | ≥6 |

| Application | Magnesium and High Activity Magnesium Alloys |

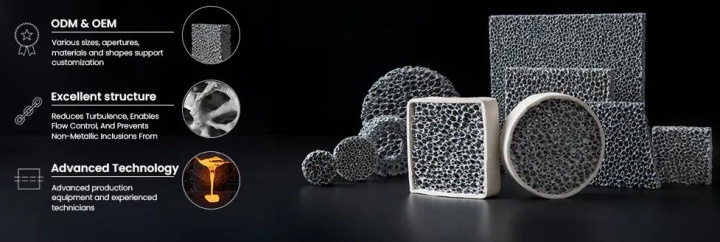

Working Principle:

Magnesia Ceramic Foam Filters feature a porous structure that allows molten metal to pass through while trapping impurities such as oxides and non-metallic inclusions. The filters also eliminate gas bubbles formed during casting, producing clean, pure castings with improved mechanical properties. These filters are suitable for use in a variety of metal casting processes, ensuring high-quality, defect-free castings.

Applications:

- Automotive

- Aerospace

- Foundries

- Chemical Manufacturing

- Metal Casting

Why Choose Our Magnesia Ceramic Foam Filter?

Our filters are manufactured using the highest quality magnesium oxide, ensuring top-tier performance in molten metal filtration. With their excellent thermal stability, high chemical resistance, and superior mechanical properties, our magnesia ceramic foam filters are the ideal solution for improving the quality and efficiency of your casting process. By reducing inclusions, improving the mechanical properties of the castings, and enhancing the overall casting process, our filters help increase productivity and reduce scrap rates, ultimately boosting profitability.