Product Description

With the rise of diesel engine vehicles, particulate emissions—primarily carbon—have contributed significantly to environmental pollution. To address this, diesel engine regulations now mandate that particulate emissions in diesel passenger vehicles must be reduced to below 2.0g/mile. The Catalytic Converter Ceramic Honeycomb plays a crucial role in achieving this goal, reducing harmful carbon particulates by over 80%. Its ceramic honeycomb structure improves filtration efficiency, supporting diesel particulate filters (DPF) to capture and eliminate harmful emissions effectively.

Exhaust gases pass through the DPF, which is often coated with precious metals such as platinum (Pt), palladium (Pd), and rhodium (Rh). These precious metals help trap carbon particulates in a metallic fiber felt filter. Once particulate accumulation reaches a certain level, the system initiates automatic regeneration through a tail burner. This process burns off the collected particulates, converting them into non-toxic CO2 and reducing pollution, while ensuring the engine operates efficiently.

Catalytic Converter Ceramic Honeycomb works in synergy with the DPF, enhancing both filtration and catalytic performance, and significantly lowering emissions from diesel engines.

Product Features:

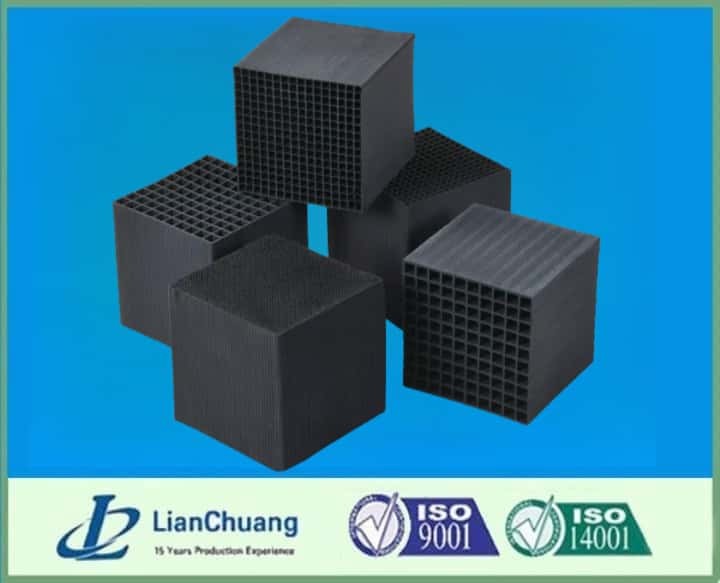

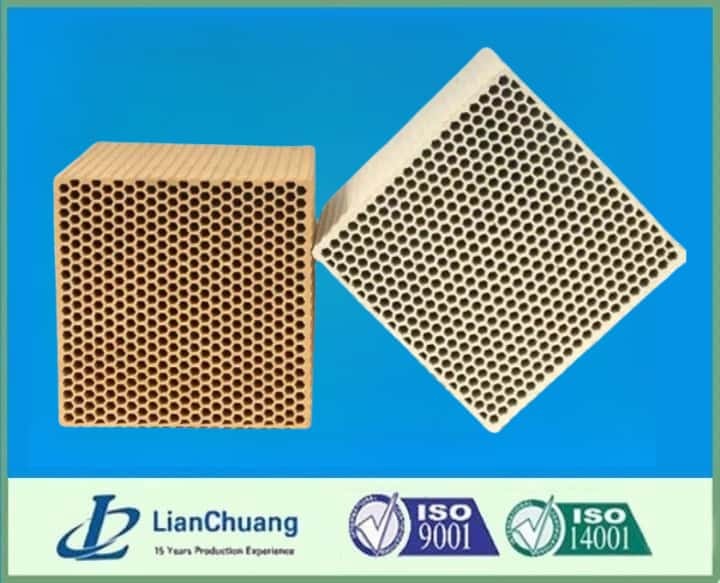

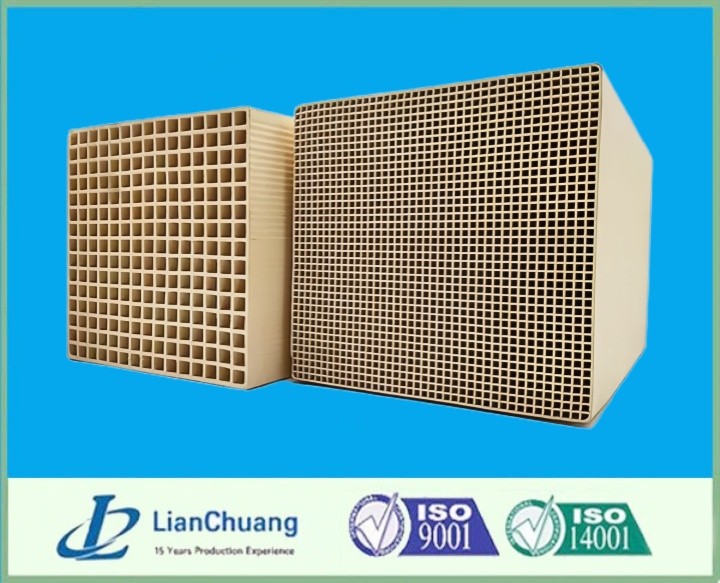

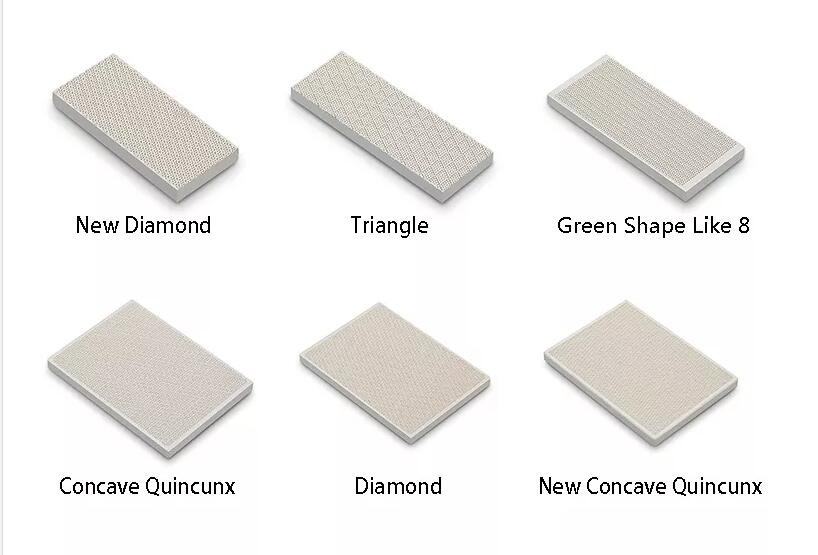

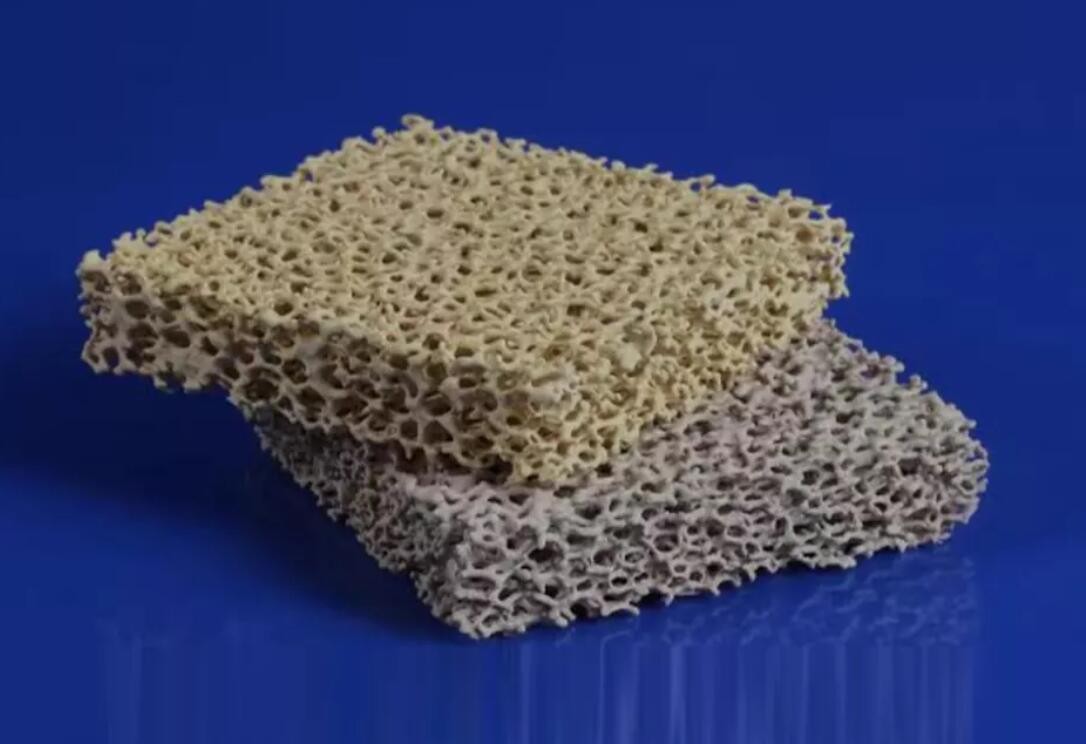

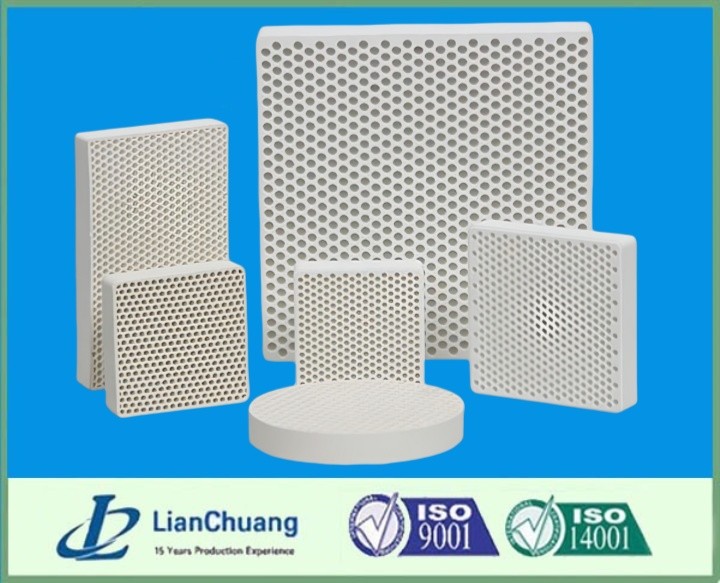

- High Catalytic Efficiency: Ceramic honeycomb design provides a large surface area, optimizing catalytic reactions and enhancing filtration efficiency, playing a key role in reducing carbon particulate emissions.

- Advanced Particulate Filtration: Ceramic honeycomb acts as a secondary filtration system, capturing fine carbon particulates alongside the DPF and ensuring over 80% of harmful carbon particulates are filtered out.

- Automatic Regeneration: As particulate buildup increases, leading to higher pressure loss, the system automatically triggers regeneration. The ceramic honeycomb aids in burning off accumulated particulates, converting them into harmless CO2 and restoring optimal performance.

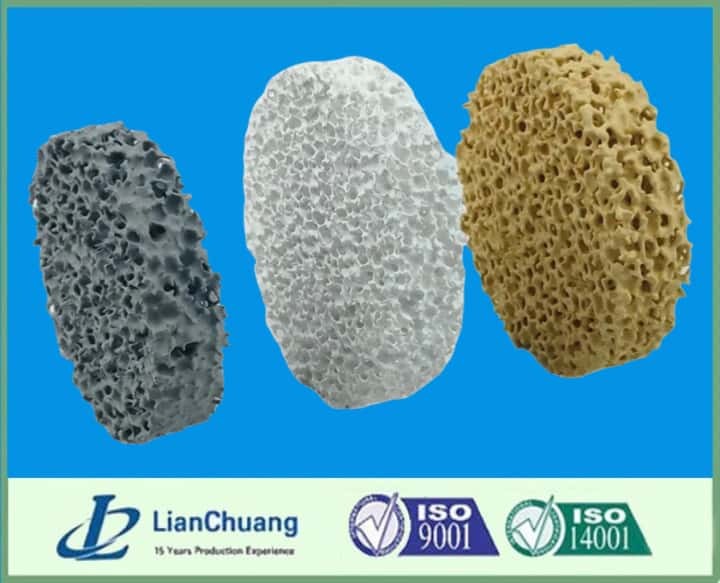

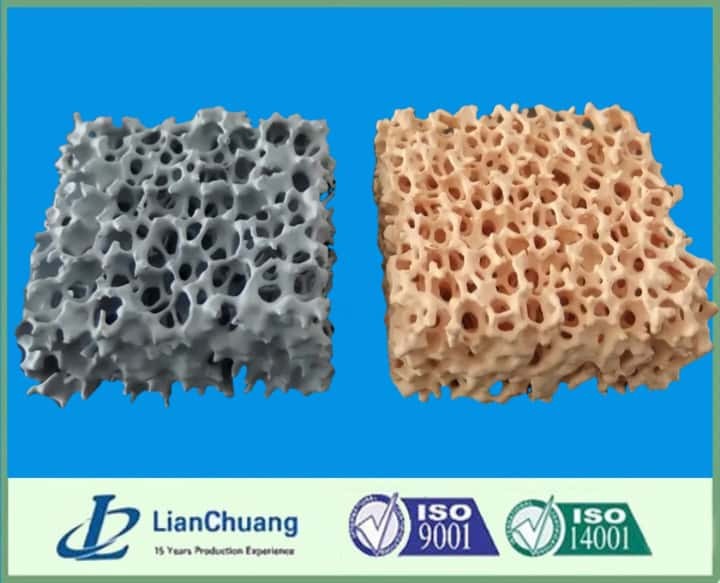

- High-Temperature Resistance: The ceramic honeycomb is designed to withstand extreme temperatures required for the combustion process, ensuring durability and consistent performance.

- Corrosion Resistance: With exceptional corrosion resistance, the ceramic honeycomb remains effective in harsh chemical environments, contributing to the longevity of the filtration system.

- Eco-Friendly and Energy-Saving: The ceramic honeycomb design ensures compliance with global emission standards, reducing environmental pollution while enhancing fuel efficiency.

- Durability: The ceramic honeycomb is engineered for long-lasting performance, reducing maintenance needs and extending the lifespan of the exhaust filtration system.

- Lightweight Design: Compared to traditional metal catalytic converters, the ceramic honeycomb is lightweight, reducing the overall weight of the vehicle and improving fuel efficiency.

Application Range:

The Catalytic Converter Ceramic Honeycomb is suitable for a wide range of gasoline and diesel-powered vehicles, including compact cars, SUVs, trucks, and construction machinery. It helps ensure compliance with stringent emission regulations.

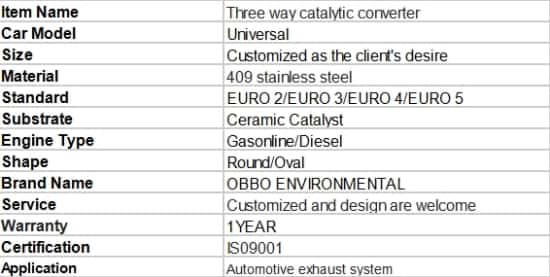

Technical Specifications:

- Material: High-temperature-resistant ceramic

- Porosity: Customizable

- Size: Customizable based on vehicle model

- Working Temperature Range: Up to 1200°C

Specification:

All products meet Euro 2, 3, 4, 5, and 6 emission standards and OBD.

- Available in standard or custom configurations.

- Automatic robot cutting and welding for precise installation positions.

- Excellent anti-poisoning and aging properties.

- Long service life and high-temperature resistance.

- Purification efficiency up to 98%, reducing emissions of CO, HC, and NO2.

- Honeycombed metal or ceramic substrate with rich precious metals.

- Includes heat shield to protect the lower parts of the vehicle from high temperatures.

Advantages:

- High flow and large carrier design using 409 thickened stainless steel for durability and corrosion resistance.

- Smooth surface and reasonable structure, tested for quality control to ensure reliability.

- Reinforced welding to prevent loosening, reducing the effects of vehicle bumps.

- Standard catalyst to improve filter cartridge efficiency.

- High flow design provides more oxygen to the engine, improving power and performance.

- Converts exhaust gases into carbon dioxide, water, and nitrogen, eliminating alarms and reducing fuel consumption and noise.

The Catalytic Converter Ceramic Honeycomb plays a critical role in reducing diesel engine emissions by enhancing filtration and catalytic processes. In conjunction with the diesel particulate filter (DPF), it captures and burns off harmful carbon particulates, converting them into harmless CO2. By meeting stringent emission standards, improving vehicle performance, and contributing to cleaner air, the ceramic honeycomb is an essential part of the transition to eco-friendly transportation solutions.