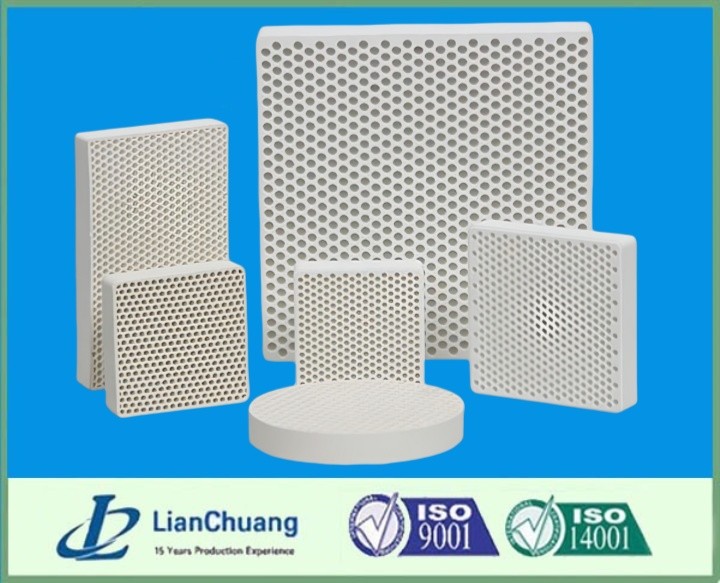

Product Description

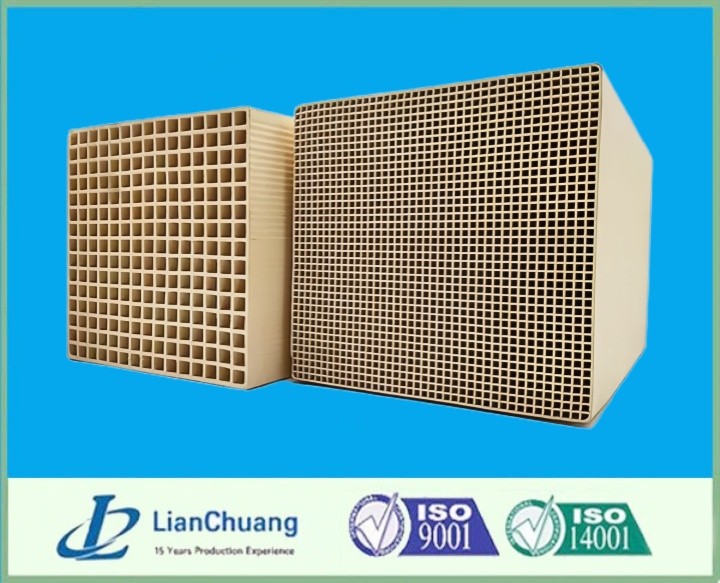

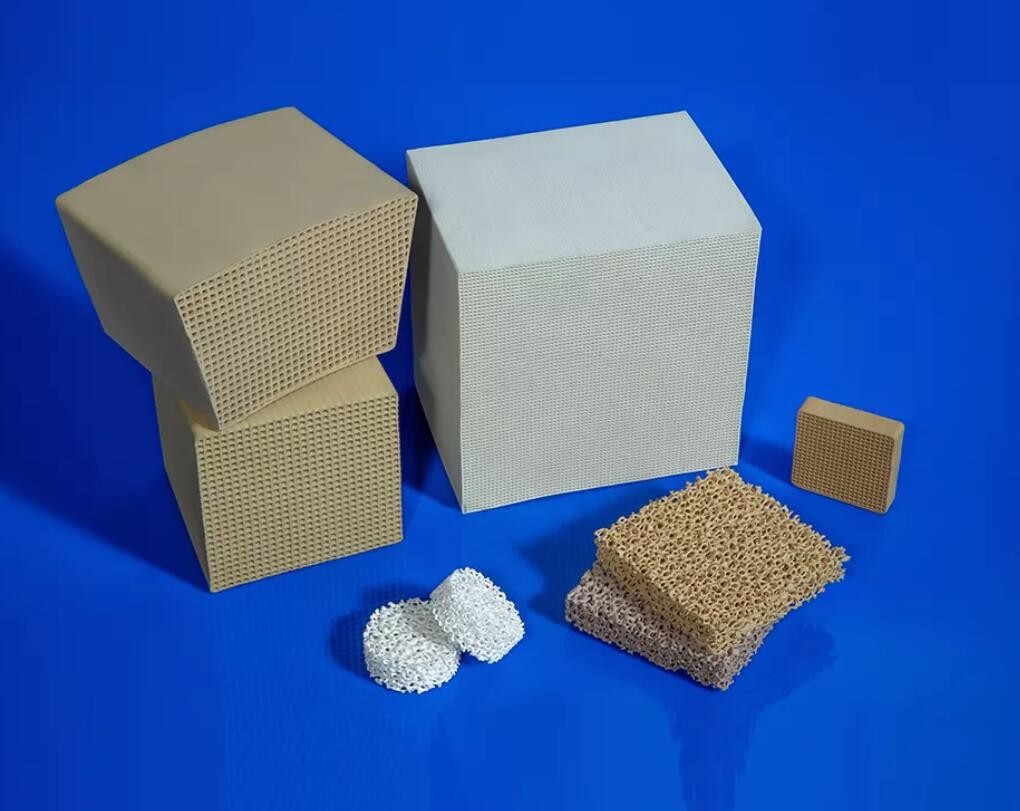

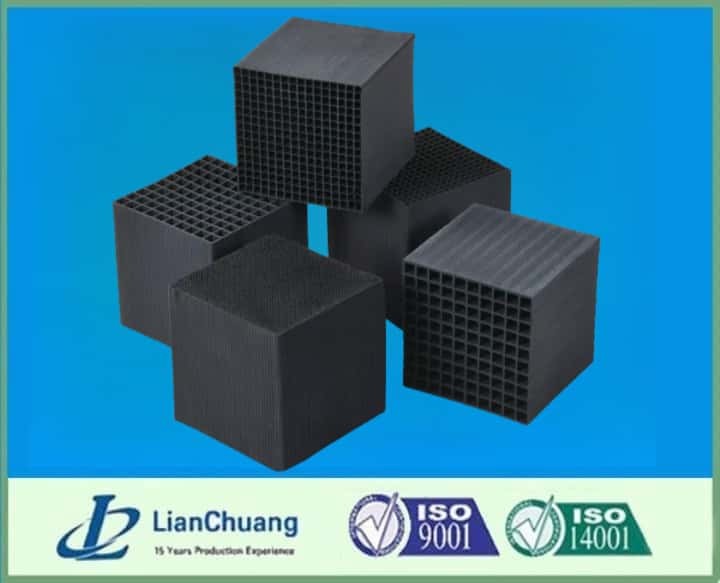

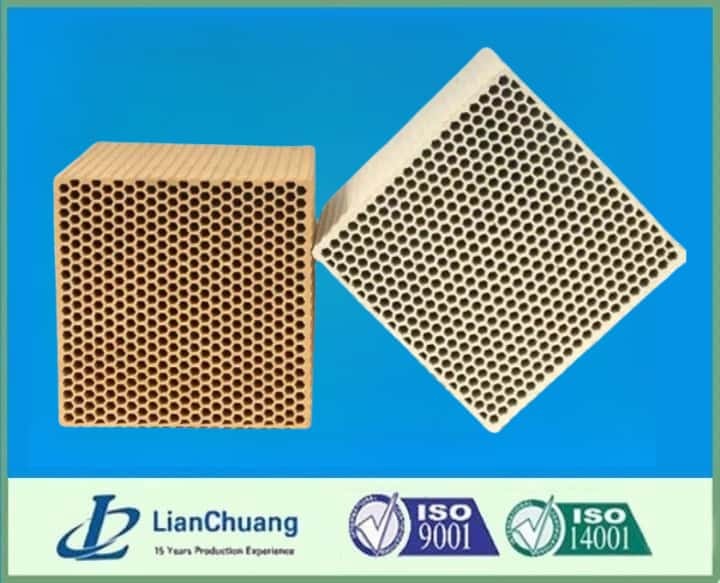

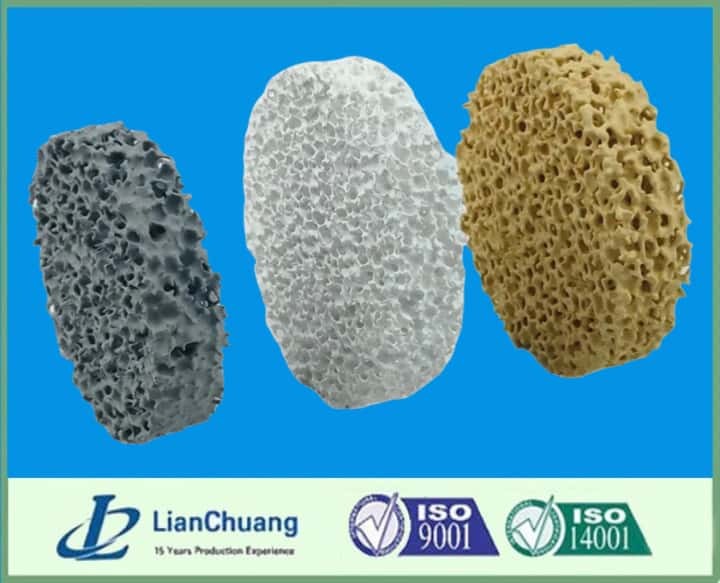

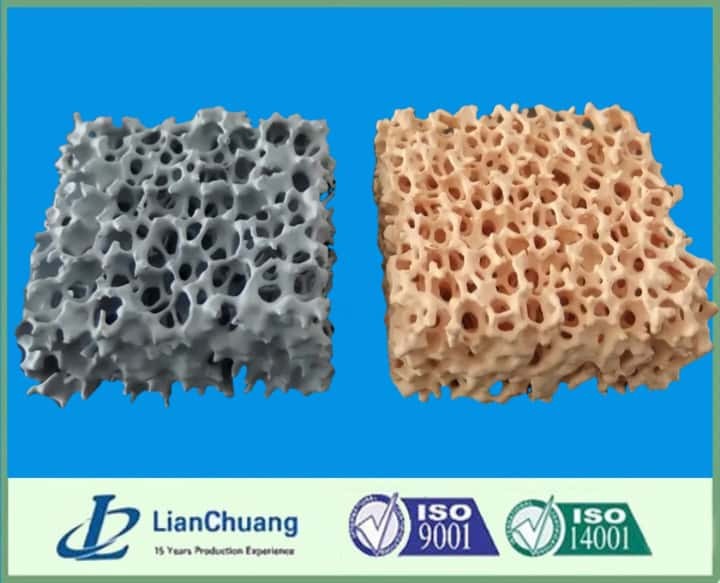

Cordierite Ceramic Honeycomb For Heat Exchanger (RTO) is widely used in heat transfer, storage , waste gas purification and catalyst carrier for RTO, RCO plants . Material: Alumina , Mullite, Cordierite eramic Honeycomb Monoliths are specified as structured RTO media (and ceramic saddles are a form ofrandom RTO media).The cordierite honeycomb ceramic, which has a low thermal expansion coefficient, good thermalstability and thermal shock resistance, low back pressure, is widely used as catalytic carrier, especially forauto exhaust purifier.

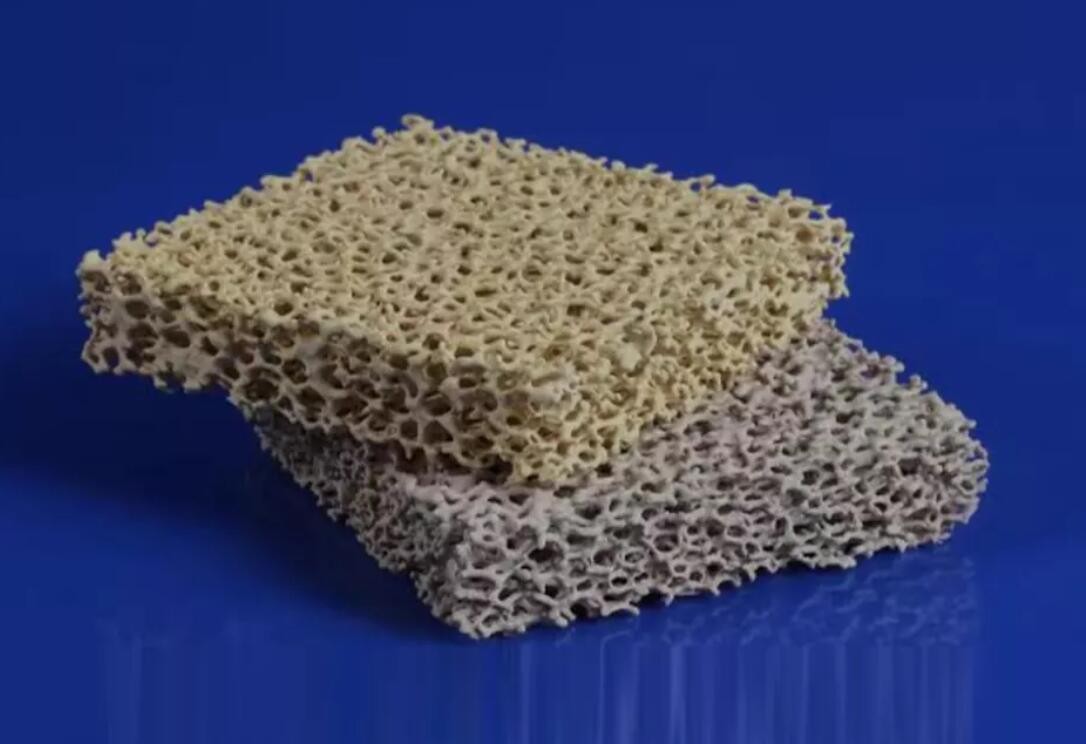

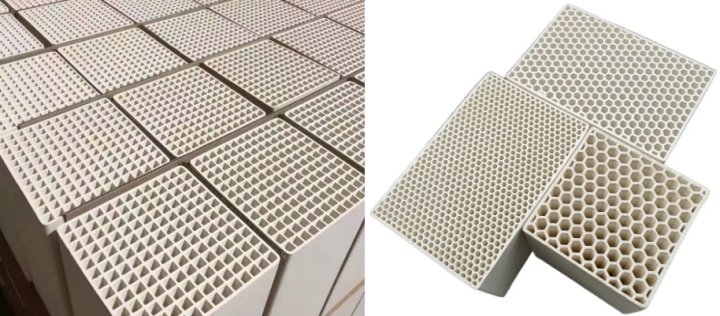

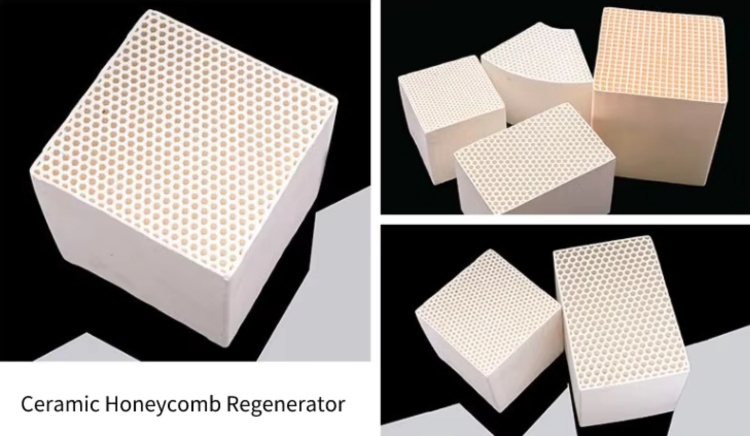

Regenerative Thermal Oxidizers are used to destroy Hazardous Air Pollutants (HAPs), Volatile OrganicCompounds (VOCs) and odorous emissions that are often discharged from industrial processes. RTO Honeycomb Ceramic Heat Exchanger: Honeycomb ceramics are a new kind ofindustrial ceramic product developed in recent years. They have a large surface area, higher air ventrate, good heat functions, stable chemical properties etc. Ceramic Honeycomb materials are mainly as the support of catalyst, heat exchange media and filtratesubstrate. Ceramic Honeycomb Materials: Cordierite, Porcelain, Mullite, Alumina, Stoneware, etc.Honeycomb ceramic products have a specific heat capacity exceeding 1000 J/kg·K and can withstand operating temperatures of 1700°C or higher. These materials are ideal for use in heat storage systems in furnaces like reheating furnaces, ovens, soaking pits, and cracking furnaces, contributing to over 40% fuel savings, boosting production by more than 15%, and ensuring flue gas emissions are kept below 150°C.

RTO ceramic honeycomb offer several advantages, including a larger specific surface area and enhanced strength compared to other filler shapes. This design leads to more uniform vapor-liquid distribution, reduces bed resistance, improves performance, and extends the service life of the system. They are widely applicable in industries such as petrochemicals, pharmaceuticals, and fine chemicals, delivering significant performance benefits.The honeycomb structure, made from ceramic material, serves as a catalyst carrier. RTO ceramic honeycomb features a special coating composed of precious metals, rare earth elements, and transition metals, which significantly enhances the product's catalytic activity, thermal stability, durability, and overall strength.

RTO Ceramic Honeycomb Key Features

| Chemical&Physical Index | Cordierite | Dense cordierite | Alumina | Mullite | Corundum-mullite | |

| Chemical | SiO2% | 45-55 | 35-45 | 25-35 | 25-38 | 15-25 |

| Composition | Al2O3% | 35-45 | 45-50 | 55-65 | 60-70 | 65-80 |

| MgO% | 10-15 | 5-10 | 1-3 | 1-3 | 1-3 | |

| K2O+Na2O3% | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| Fe2O3% | <1.5 | <1.5 | <1.5 | <1.5 | <1.5 | |

| Thermal EXpansion Coefficient | 10-6/K-1 | <2 | <4 | <4 | <5 | <7 |

| Specific Heat J/kg.K | 830-900 | 850-950 | 850-1000 | 900-1050 | 900-1100 | |

| Working Temperature℃ | <1300 | <1300 | <1350 | <1450 | <1500 | |

| PS: we also can make products at your request and actual operating condition | ||||||

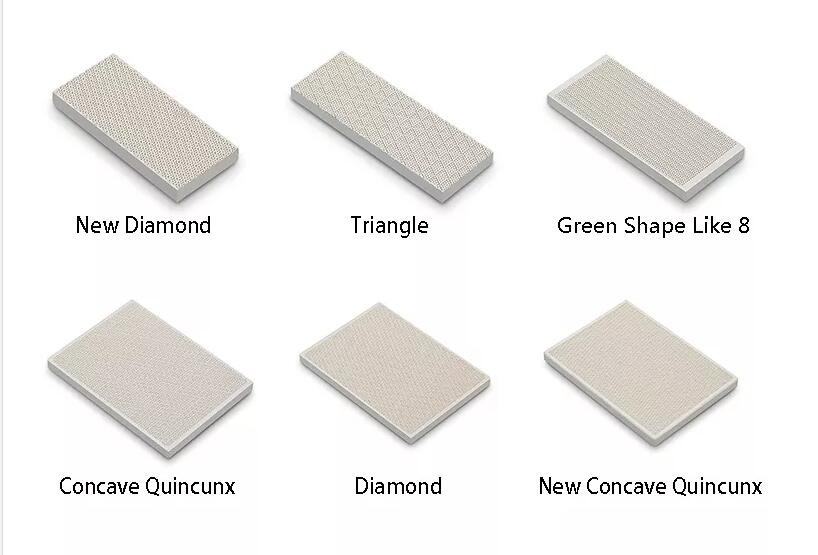

RTO Ceramic Honeycomb Size Features

| Size (mm) | Hole Qty (N*N) | Hole density cpsi | Hole Diameter (mm) | Wall thickness (mm) | Porosity (%) |

| 150*150*300 | 5*5 | 0.7 | 2.7 | 2.4 | 81 |

| 150*150*300 | 13*13 | 4.8 | 9.9 | 1.5 | 74 |

| 150*150*300 | 20*20 | 11 | 6 | 1.4 | 64 |

| 150*150*300 | 25*25 | 18 | 4.9 | 1 | 67 |

| 150*150*300 | 40*40 | 46 | 3 | 0.73 | 64 |

| 150*150*300 | 43*43 | 53 | 2.79 | 0.67 | 64 |

| 150*150*300 | 50*50 | 72 | 2.4 | 0.6 | 61 |

| 150*150*300 | 59*59 | 100 | 2.1 | 0.43 | 68 |

RTO Ceramic Honeycomb Production Process

rto ceramic honeycomb Package & Delivery