Product Description

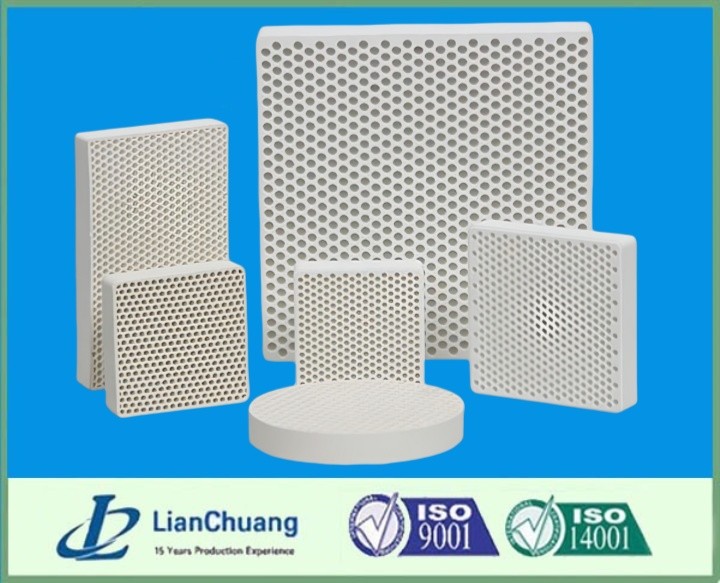

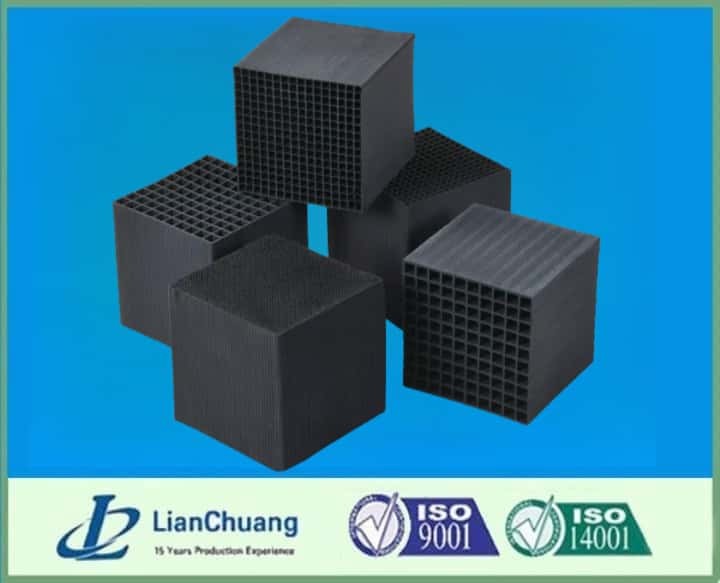

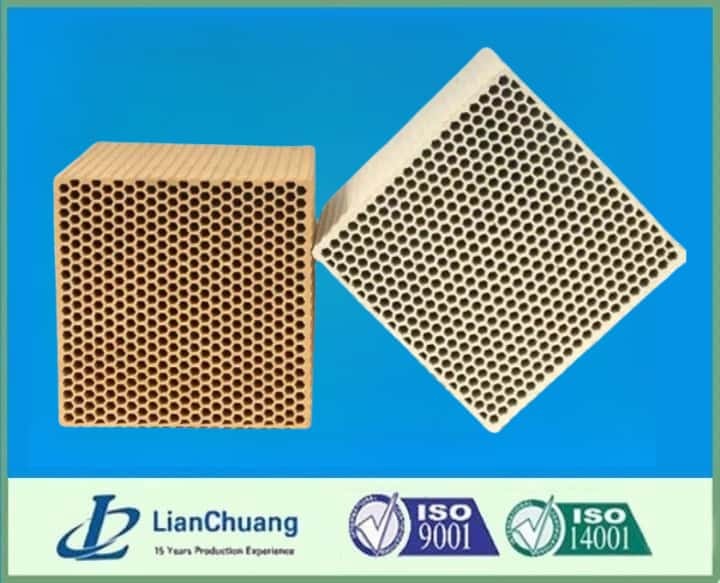

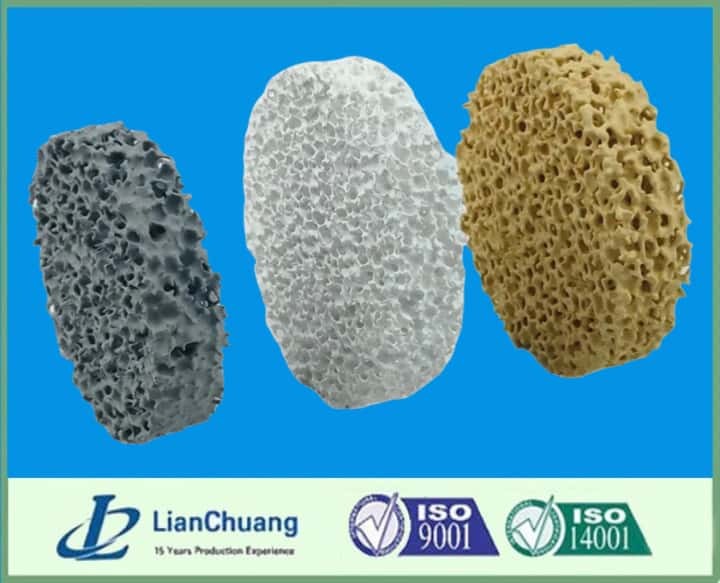

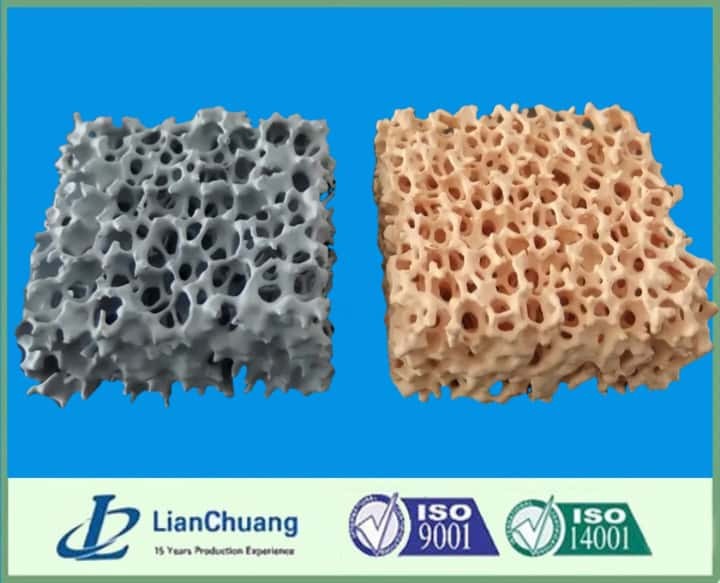

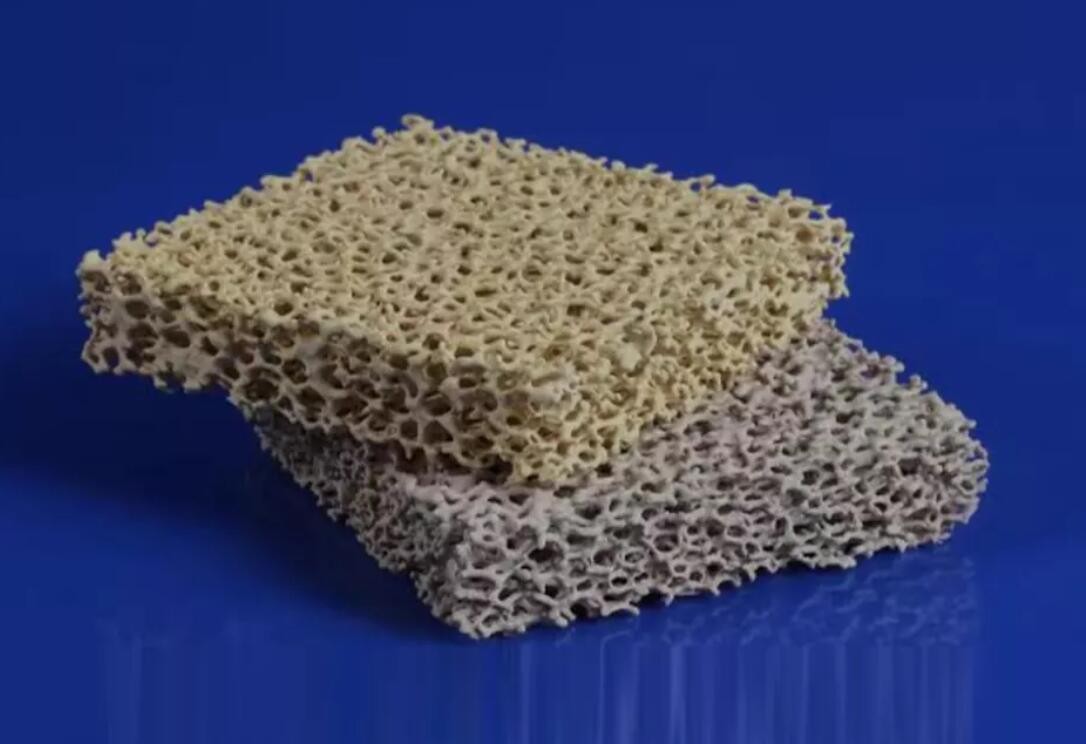

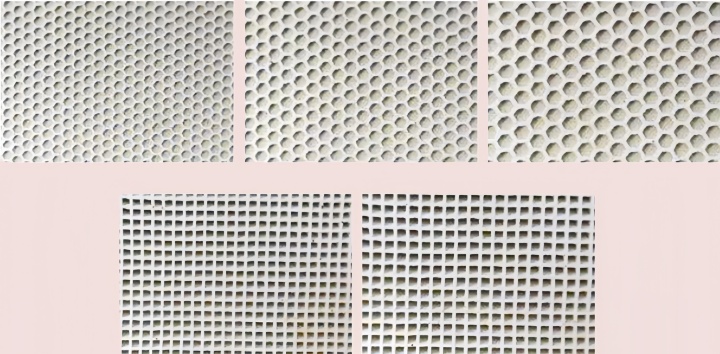

The Porous Honeycomb Ceramic Filter is an innovative solution for filtering molten metal in cast iron and non-ferrous alloy castings. With its high porosity, excellent thermal shock resistance, and robust strength, this filter effectively captures impurities and ensures a smooth laminar flow, preventing bubbles from entering the casting process.

Designed for the specific needs of the foundry industry, the ceramic honeycomb filter adapts to various refractoriness levels and pouring speeds. It enhances casting quality, improves machinability, reduces tool wear, and lowers manufacturing costs.

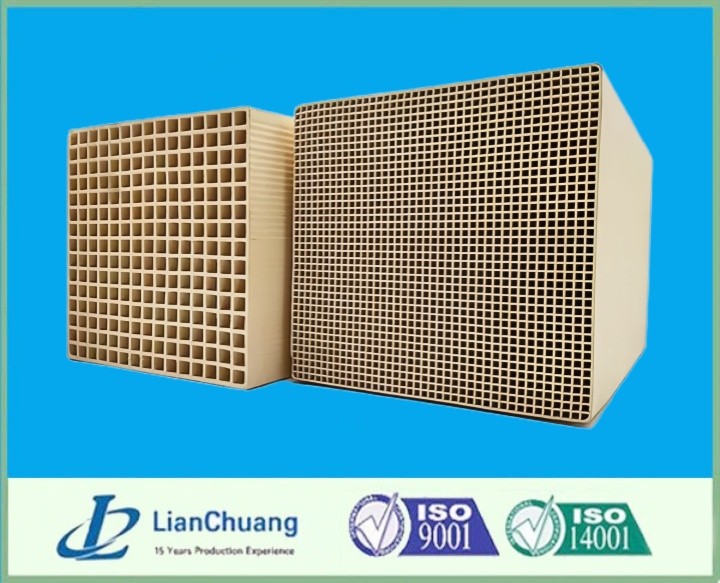

Features of the honeycomb ceramic filter

High strength: Produced using high-pressure technology for enhanced durability and stability during use.

Efficient filtration: Effectively removes inclusions, adsorbs micro-impurities, and eliminates bubbles from molten metal while maintaining a stable pass rate.

Precision fit: Ensures high dimensional accuracy, making it ideal for automated production lines by guaranteeing seamless compatibility with molds.

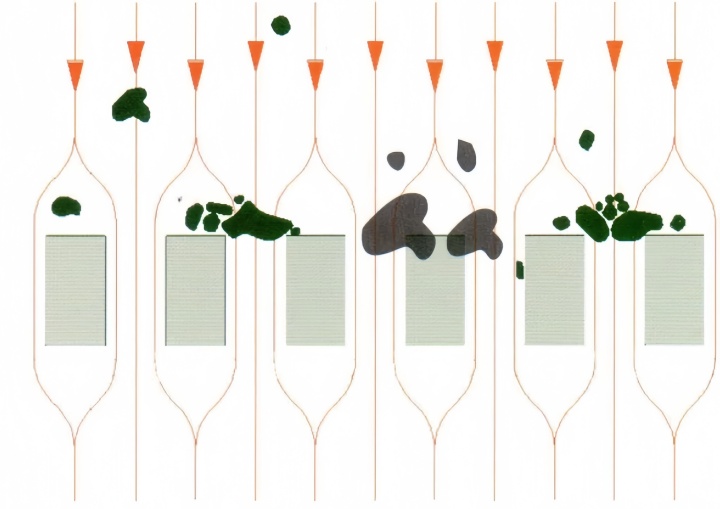

Filtration mechanism of the ceramic honeycomb filter

Sieving effect: Blocks larger slag particles at the mesh openings, preventing their entry into the casting.

Slag accumulation: Larger particles adhere to the filter, attracting smaller particles to create a multi-layered filtration effect.

Implantation: Micro-slag particles adhere to the mesh walls, ensuring thorough residue removal and enhancing the filtration process.

How to use the honeycomb ceramic filter

Positioning: Integrate the filter into the pouring system, adjusting the runner design to maximize the filter’s effective area.

Blocking point placement: Place the blocking point behind and close to the filter to avoid clogging the filter holes.

Sizing: Ensure the filter area is 3-6 times larger than the combined smallest areas of all inner runners to optimize flow.

Model design: Incorporate the filter into the model system, ensuring horizontal placement when dividing horizontally.

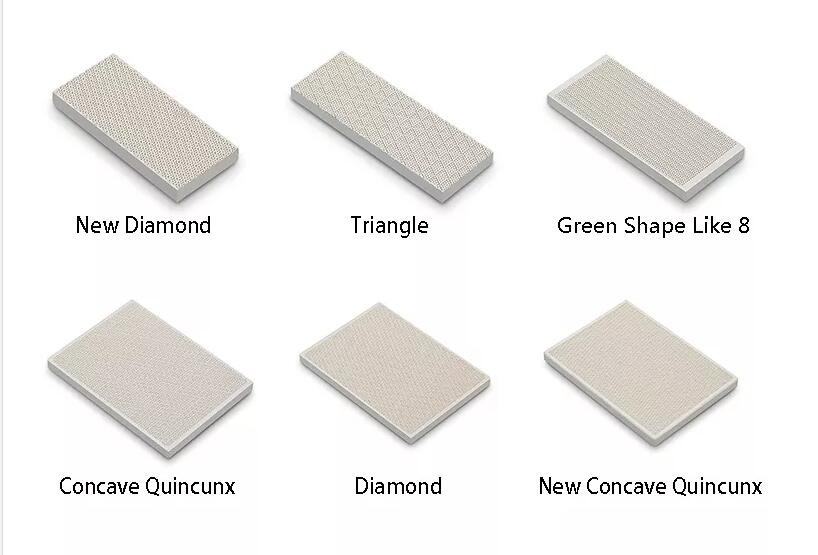

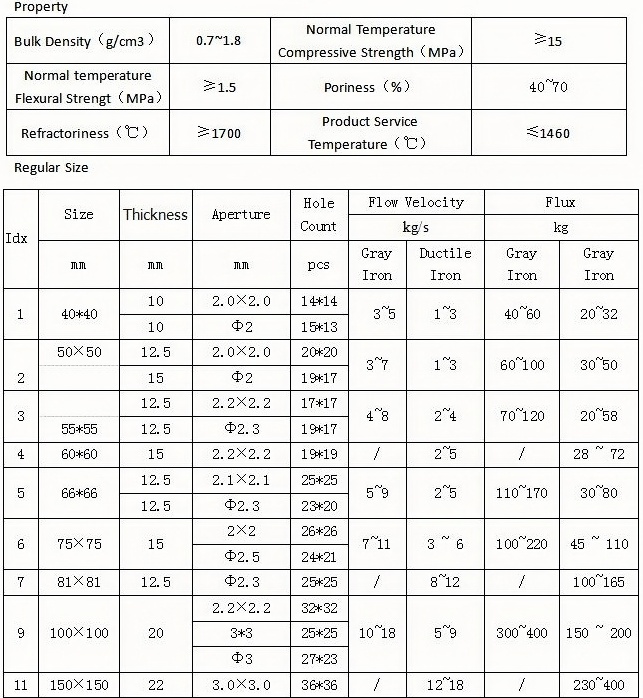

Specifications of the honeycomb ceramic filter

Applications of the porous ceramic honeycomb filter

The ceramic honeycomb filter is widely used in the casting of materials such as cast iron, ductile iron, stainless steel, and aluminum alloys. Its versatility and efficiency make it an essential component in modern foundry operations.

By adopting a honeycomb ceramic filter, foundries can achieve improved casting quality, better machinability, and cost-efficient production. This filter is a critical tool for optimizing molten metal filtration and ensuring precision in the casting process.

Whether you aim to refine your gating system or enhance casting performance, the ceramic honeycomb filter is the ideal choice for foundry applications.