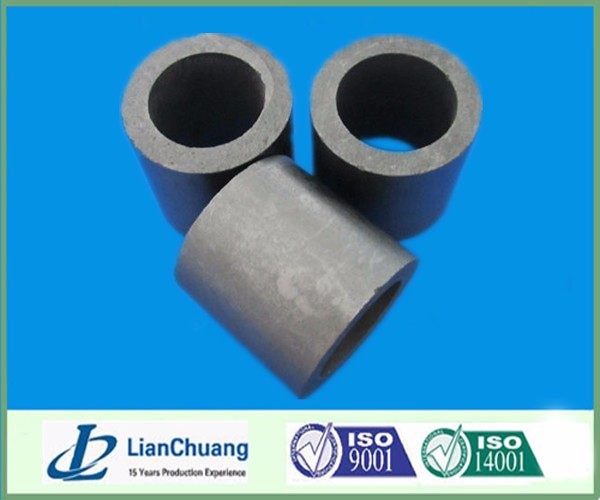

Product Description

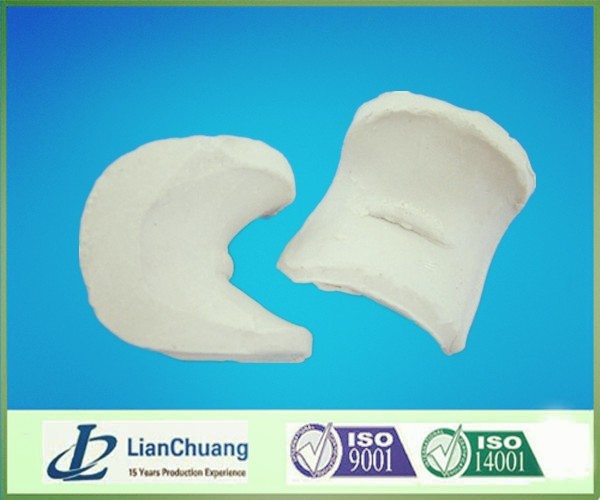

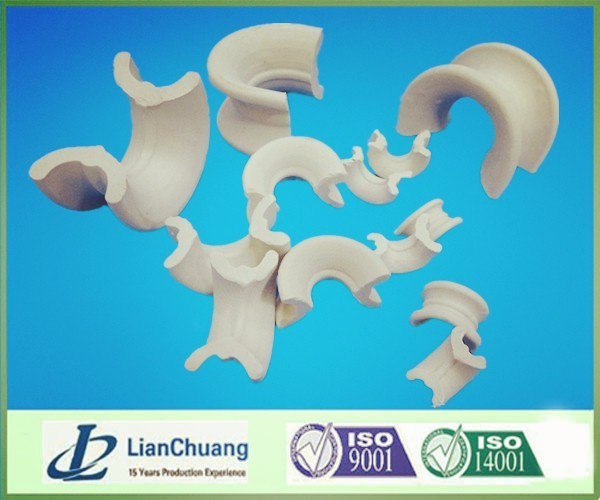

ceramic berl saddles are the kind of older generation packing just like ceramic raschig ring, it also have a smilar shape asceramic saddles, but berl saddles’ internal and external surfaces are open entirely. So ceramic berl saddle is an opening packing shaped like a saddle without inside and outside, the berl saddles also perform better as compared to raschig ring in the aspects of even fluid distribution and low resistance. And ceramic berl saddles makes lower pressure against the inner wall of the tower than the ring packing. As ceramic berl saddles are made from ceramic , so it can can resist various inorganic acids, and organic acids and organic solvents except hydrofluoric acid’s corrosion.

Ceramic berl saddles tower packing can be applied in fertilizer, gas, chemical, petrochemical and environmental protection industries. However , ceramic berl saddles also have its own weakness, its more more easy to be fragile than Raschig ring at the bed plate. That’s the reason we try our best to provide different ceramic random tower packing product for our customer, they can make the right choice based on the specific use conditional requirements.

Ceramic Berl Saddles product model:

19mm, 25mm ,38mm,50mm

Specifications of Ceramic Berl Saddles :

Size | Specific Surface | Void Volume | Number per m3 | Bulk Density | |

mm | inch | m2/m3 | % | pcs/m3 | Kg/m3 |

19 | 3/4 | 225 | 58 | 83950 | 725 |

25 | 1 | 206 | 61 | 43250 | 640 |

38 | 1.5 | 110 | 72 | 12775 | 617 |

50 | 2 | 95 | 72 | 7900 | 650 |

Chemical Composition of Ceramic Berl Saddles:

SiO2 | Al2O3 | Fe2O3 | K2O+Na2O | CaO |

>70% | 17-23% | <1% | 2-3% | <1-2% |

Note:

Our factory can make special ceramic berl saddles’s specification for customer’s special request.