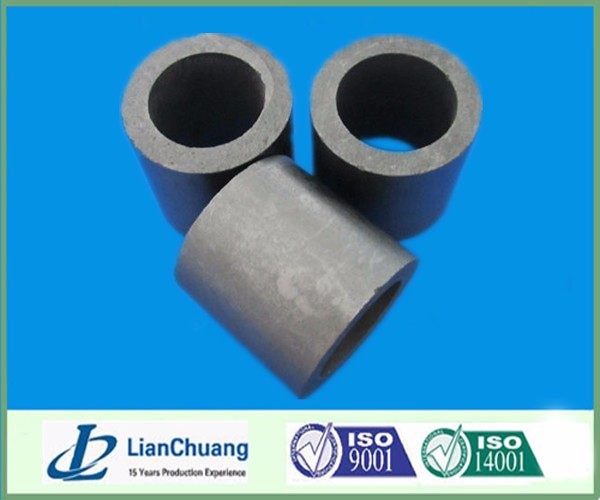

Product Description

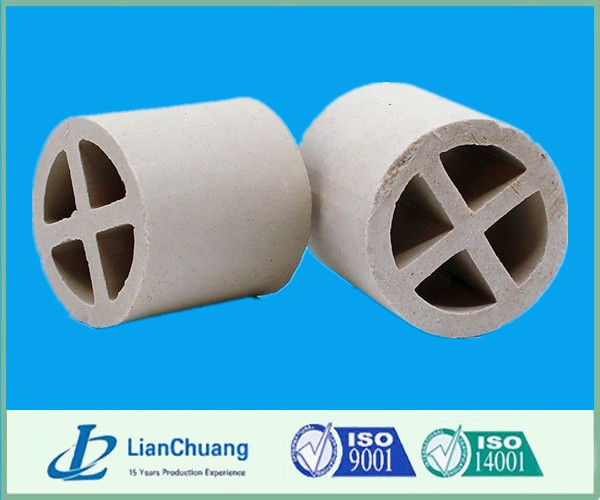

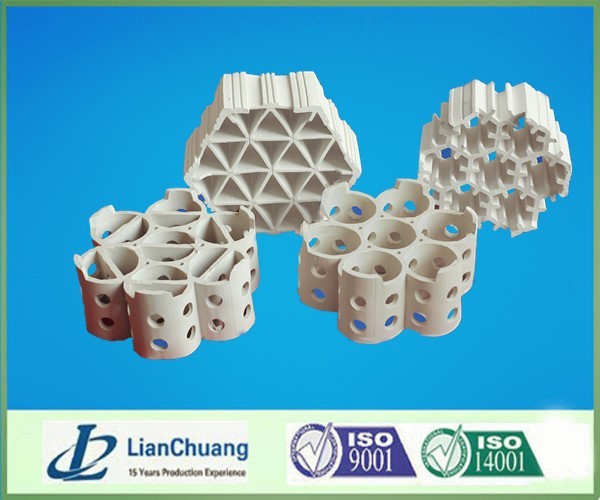

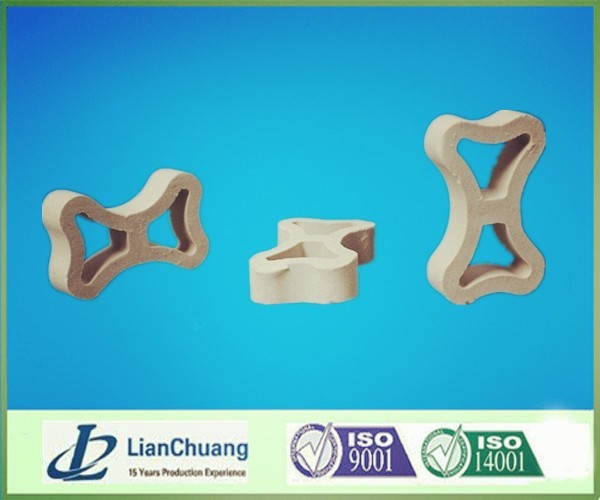

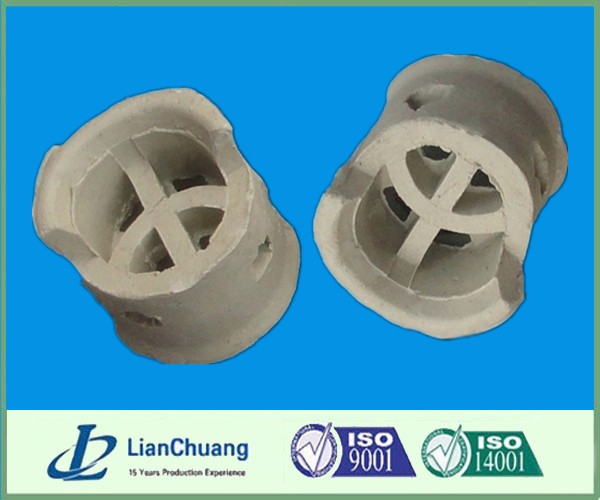

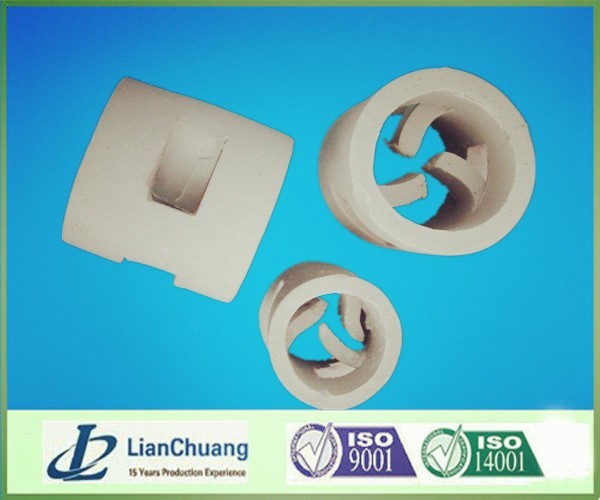

Ceramic Cross Partition Ring is a kind of random packing further improved on the basis of Raschig Ring, adding the cross clapboard inside the ring. It increases the rings surface area, improving significantly the mass transfer efficiency of vapor and liquid. ceramic cross partition rings has excellent acid resistance and heat resistance. It can resist to corrosion of variousinorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.

Generally, ceramic cross partition ring is required to stack orderly in the column due to its big size. Currently, ceramic cross partition ring, size between Φ80-Φ150mm, are used as the support material of other random packing at the bottom of column, which accumulation voidage is over 60%. With the characters of high mechanical strength, high chemical stability, and excellent heat endurance, Ceramic Cross Partition Ring can resist high temperature, acid (except HF), alkali, salt and various organic solvents. It’s widely applied in various packing towers of desiccation, absorption, cooling, washing, and regeneration in industries of petrochemical, chemical, metallurgy, gas and oxygen generation.

Technical Date: of ceramic cross rings:

| Size (mm) | Spec (mm) | Number (n/m3) | Bulk density (kg/m3) | Surface area (m2/m3) | Free volume (%) | Dry Packing Factor (m-1) |

|---|---|---|---|---|---|---|

| 50 | 50*40*50*5 | 6400 | 600 | 145 | 600 | 565 |

| 80 | 80*64*80*8 | 1950 | 820 | 120 | 820 | 356 |

| 100 | 100*80*100*10 | 1000 | 850 | 110 | 850 | 252 |

| 120 | 120*96*120*12 | 370 | 860 | 75 | 860 | 146 |

| 150 | 150*120*150*15 | 295 | 980 | 60 | 980 | 101 |

Chemical Analysis:

| Composition | Value |

|---|---|

| SiO2 | >73% |

| Al2O3 | 17-25% |

| Fe2O3 | <1.0% |

| CaO | <0.5% |

| MgO | <0.5% |

| K2O+Na2O | 2-4% |

| Other | <5% |