Product Description

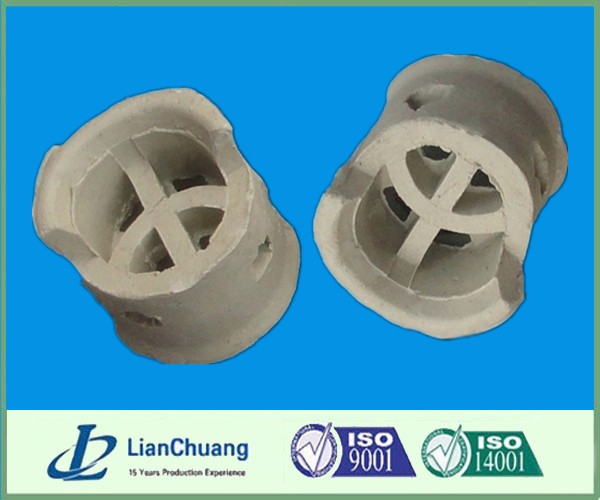

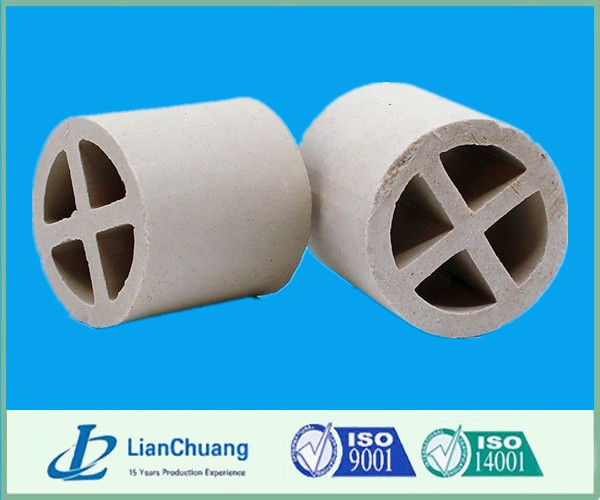

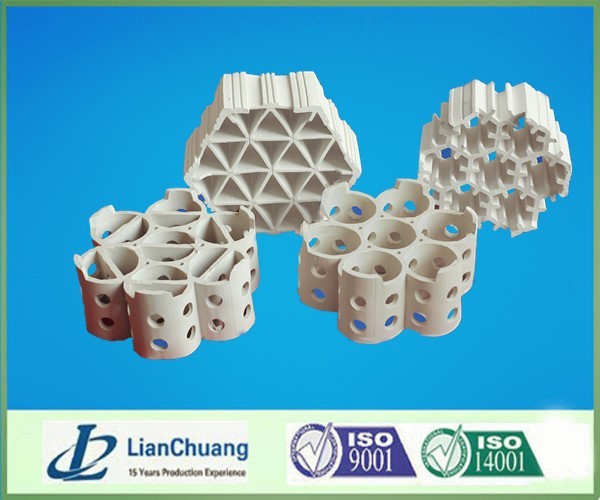

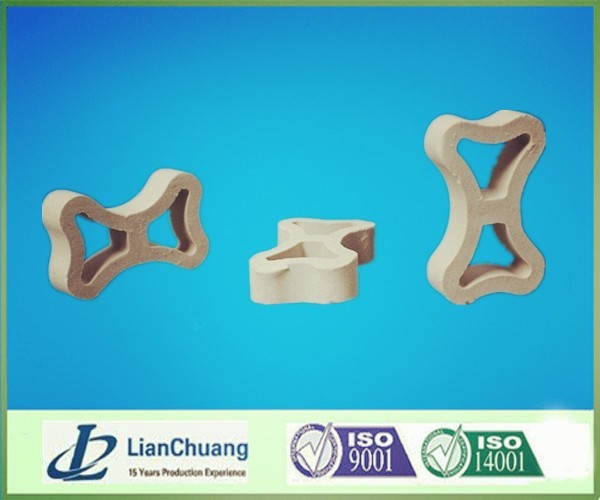

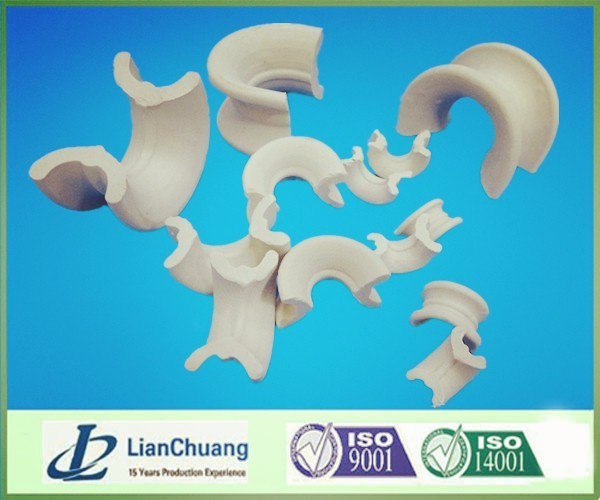

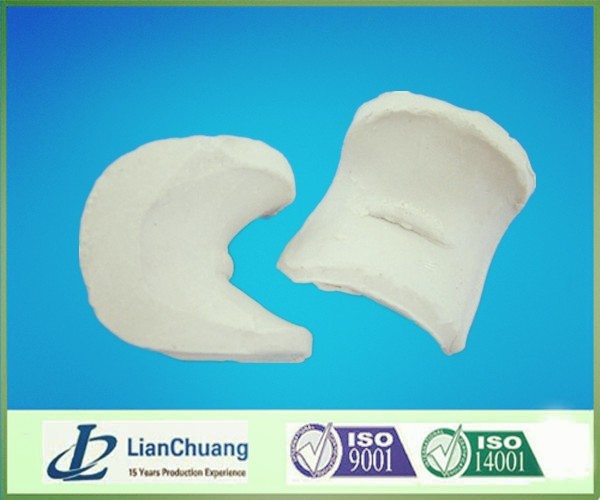

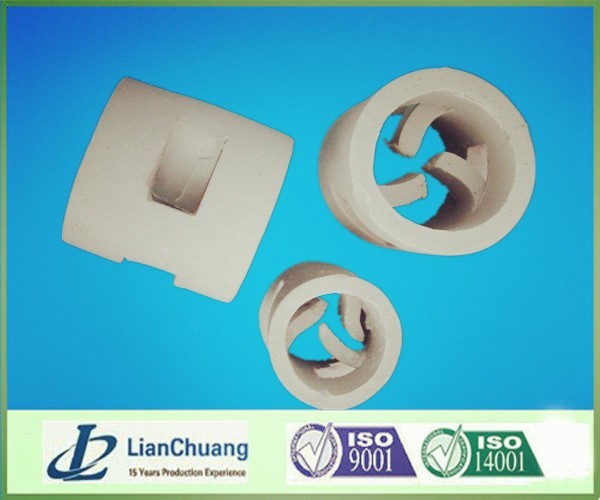

Ceramic Conjugate Ring is a type of random packing that evolved from the Cascade Ring. It is designed with a unique geometric structure that combines both the ring and saddle shapes, offering the best of both worlds. The result is a packing material that promotes efficient fluid distribution and provides a larger surface area for chemical reactions, while also minimizing the resistance to flow. This structure helps to maximize the mass transfer and heat exchange processes that are critical in many chemical and industrial operations.

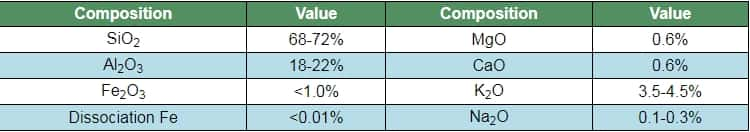

Chemical Composition of ceramic conjugate ring

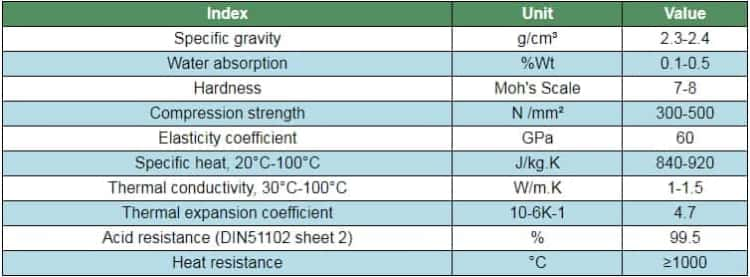

Physical Properties

Specification of Ceramic Conjugate Ring

Advantages of Ceramic Conjugate Ring

The ceramic material itself provides several inherent advantages, which further enhance the performance of the Conjugate Ring in industrial settings. Here are some of the key benefits:

1. High Chemical Resistance

Ceramic Conjugate Rings are highly resistant to various inorganic acids, organic acids, and organic solvents. This makes them suitable for applications in industries where aggressive chemical environments are common. However, they are not resistant to hydrofluoric acid, so it’s essential to avoid its presence in processes using this material.

2. Excellent Heat Resistance

Ceramic materials are known for their ability to withstand high temperatures. The Ceramic Conjugate Ring is no exception, offering outstanding heat resistance that makes it suitable for use in both high-temperature and low-temperature environments. This property is particularly valuable in industries such as chemical manufacturing, metallurgy, and coal gasification.

3. Durability and Longevity

Ceramic is a robust material, resistant to abrasion and wear, which contributes to the longevity of the packing in various applications. This durability translates to reduced maintenance costs and a longer service life for the equipment in which the rings are used.

4. Efficient Mass Transfer

The combined ring and saddle shape of the Ceramic Conjugate Ring promotes excellent gas-liquid interaction and allows for efficient mass transfer. This is crucial in processes like absorption, distillation, and scrubbing, where the effective exchange of mass and heat is a key factor in process efficiency.

5. Low Pressure Drop

The innovative design of the Ceramic Conjugate Ring results in a low pressure drop across the packing, ensuring efficient flow and minimizing energy consumption in operations. This feature makes it a cost-effective solution in large-scale industrial processes where energy savings are essential.

Applications of Ceramic Conjugate Ring

The versatility of the Ceramic Conjugate Ring makes it ideal for a wide variety of industrial applications. Some of the key industries that benefit from this packing material include:

1. Chemical Industry

In the chemical sector, the Ceramic Conjugate Ring is used in absorption towers, distillation columns, and reactors. Its resistance to a broad range of chemicals and its ability to maintain high performance under extreme conditions make it an essential material for processes such as solvent recovery, gas scrubbing, and acid recovery.

2. Metallurgy Industry

The heat-resistant properties of ceramic materials make the Conjugate Ring well-suited for use in high-temperature environments, such as in metallurgical processes where gases need to be purified or treated.

3. Coal Gas Industry

In coal gasification plants, Ceramic Conjugate Rings are used in scrubbers and absorption towers to treat gases and remove impurities. The material's high chemical resistance ensures that it remains effective even when exposed to harsh gases and liquids.

4. Oxygen-Producing Industry

The efficiency and heat resistance of Ceramic Conjugate Rings make them useful in oxygen production systems, where heat and mass transfer play a critical role in separating oxygen from air.

5. Oil and Gas Industry

The packing material is also used in gas-liquid contactors for processes such as gas absorption, separation, and desulfurization in oil and gas refineries.

6. Environmental Protection

The Ceramic Conjugate Ring is employed in various pollution control devices, such as scrubbers and gas treatment systems, where it aids in the removal of harmful contaminants from industrial exhaust gases.

The Ceramic Conjugate Ring is a superior random packing material that delivers exceptional performance in industrial applications that require high chemical resistance, heat resistance, and efficient mass transfer. Its unique combination of ring and saddle shapes optimizes fluid distribution, making it an ideal choice for applications in chemical, metallurgical, coal gas, oxygen production, and environmental protection industries. The durability, efficiency, and versatility of the Ceramic Conjugate Ring make it a reliable solution for industries aiming to improve operational efficiency and reduce maintenance costs. Whether in high-temperature environments or aggressive chemical processes, this innovative material is poised to remain a key component in modern industrial operations.