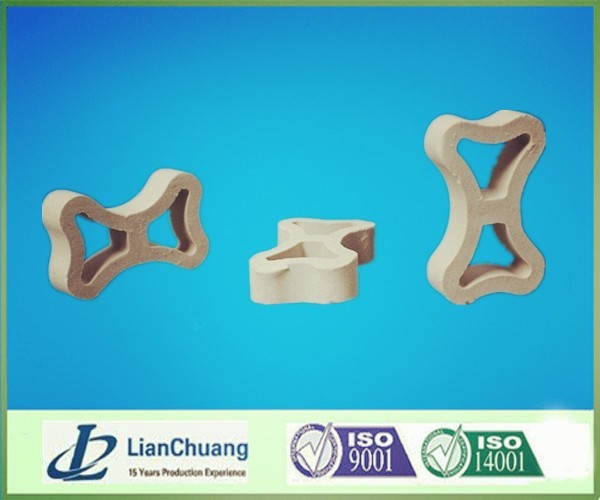

Product Description

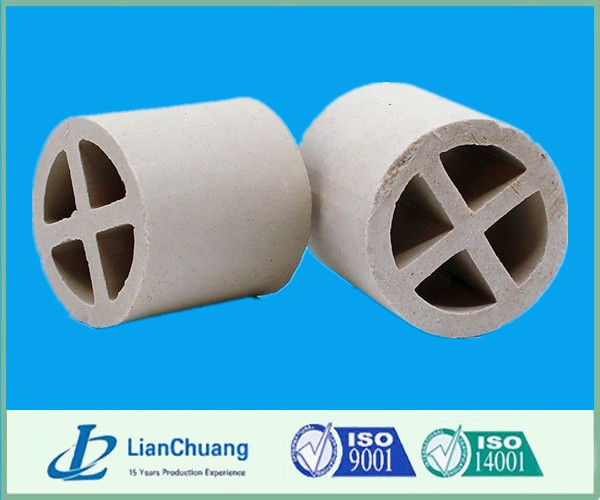

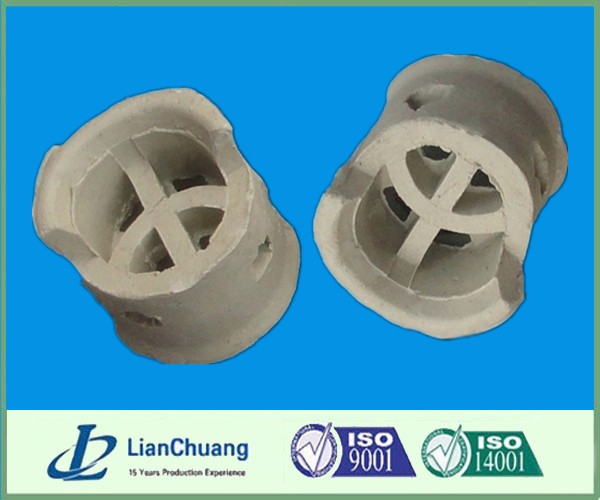

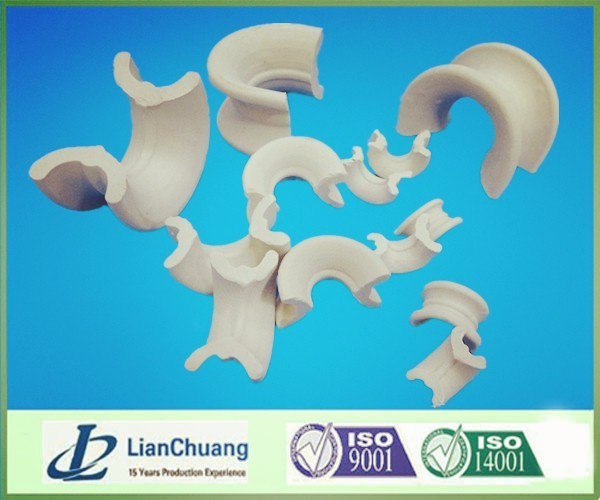

Ceramic Butterfly Rings Packing is also called Ty-Pak Heat Transfer Media, its one kind of random media. Butterfly Rings Packing is designed specifically for heat transfer applications. Ty-Pak random packing media's pressure drop is 20% lower than ceramic saddles. Ty-Pak media are made from high-quality solid pressed silicate porcelain with an aluminum oxide (Al2O3) content ranging from 17% to 23%. This composition gives them excellent durability and performance in high-temperature environments.

Its unique engineered shape prevents channeling, permits faster loading and reduces settling, which provides for consistent performance over time.This is one kind of proper RTO media significantly improves your energy usage and overall unit performance We can show you how to increase your bottom line by upgrading your current ceramic media with more thermally efficient heat transfer media.Ty-Pak is easy to load and provides a 20% lower pressure drop compared to 1-inch saddles. These advantages, combined with the high heat exchange efficiency, make Ty-Pak an economically viable packing option for RTO systems.

Features of Ceramic Ty-Pak

1. The media are made from chemical porcelain, offering excellent resistance to acids, except for hydrofluoric acid.

2. Moisture absorption is less than 0.5%.

3. The porcelain has a specific gravity of 2.25-2.35 g/cm³ and an average heat capacity of 0.22 cal/g·°C within the temperature range of 20°C to 500°C.

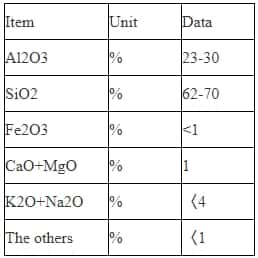

Chemical Analysis of Ceramic Butterfly Rings Packing:

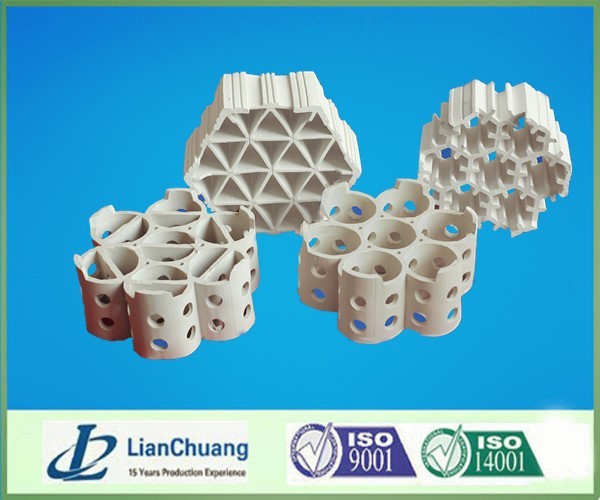

Advantage:

1. Excellent raw materials for production

2. Internal and external quality control

3. Trouble-free reactor filling due to high crush strength

4. Different common sizes are available, uncommon sizes can be customized as your request.

5. large fluid capacity & large void space & excellent acid/heat resistance

6. ISO9001:2008 certificate

7. 10 years’manufacture experience