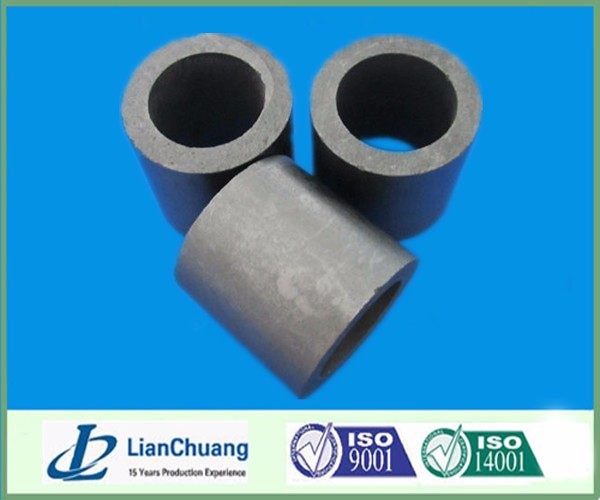

Product Description

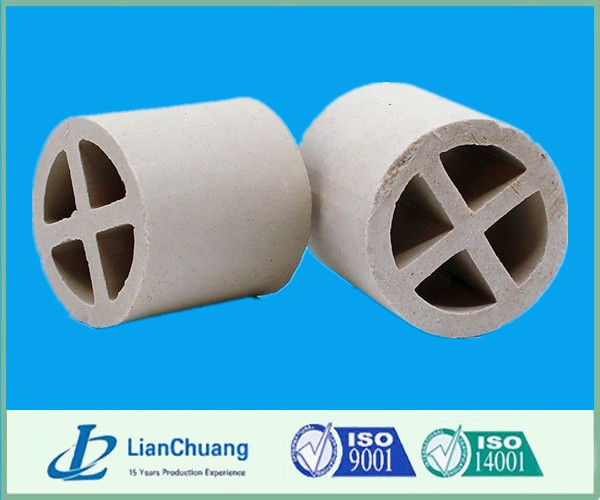

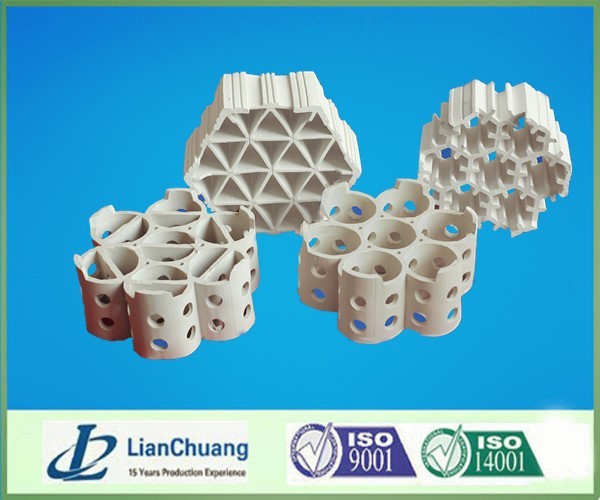

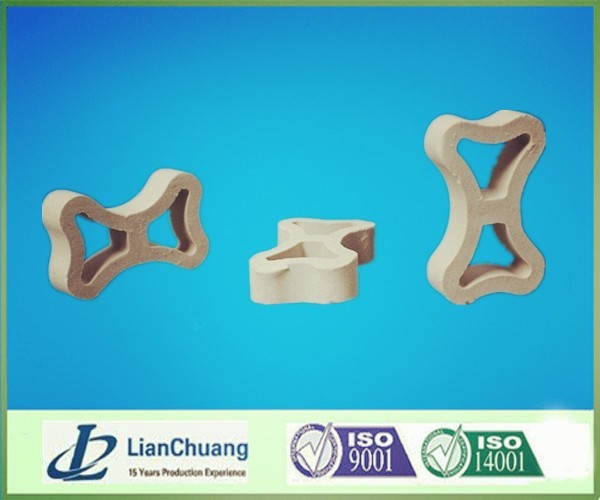

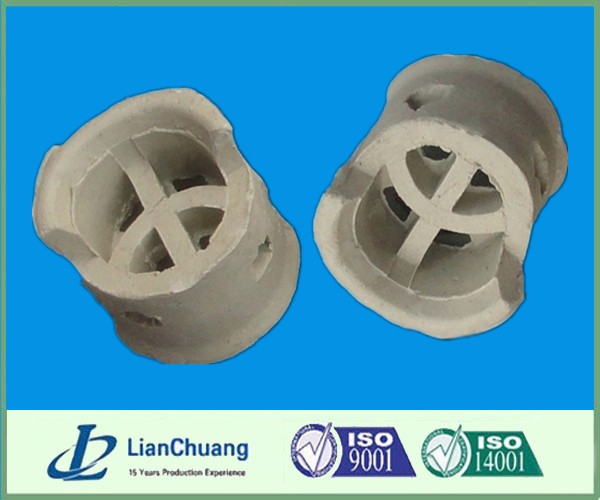

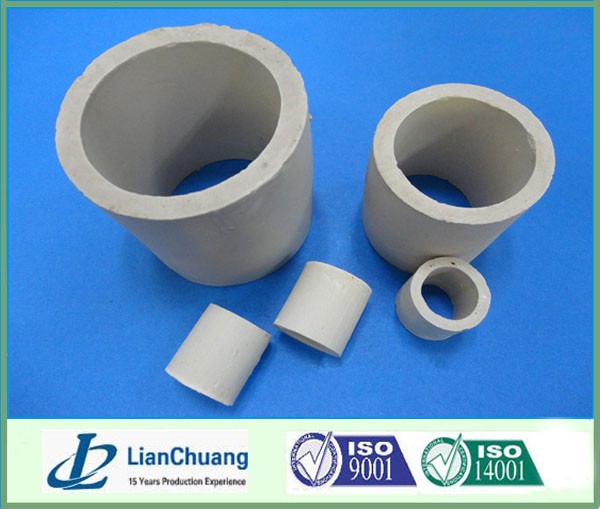

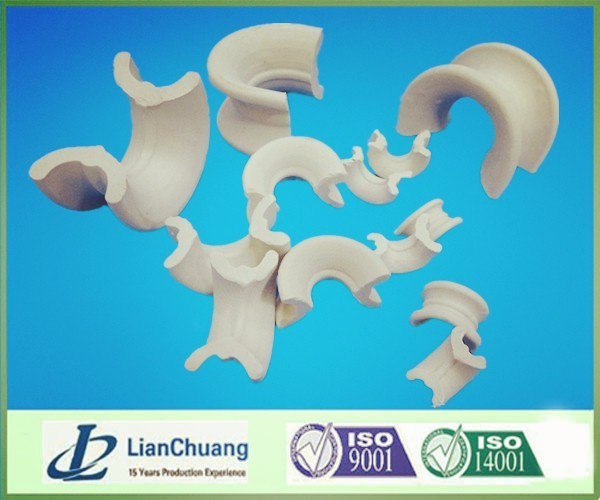

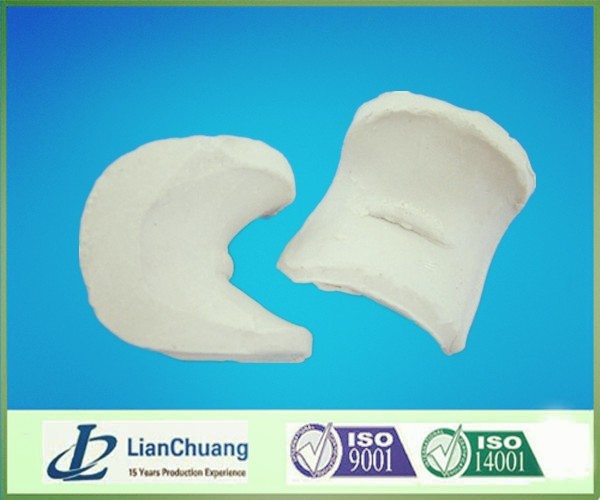

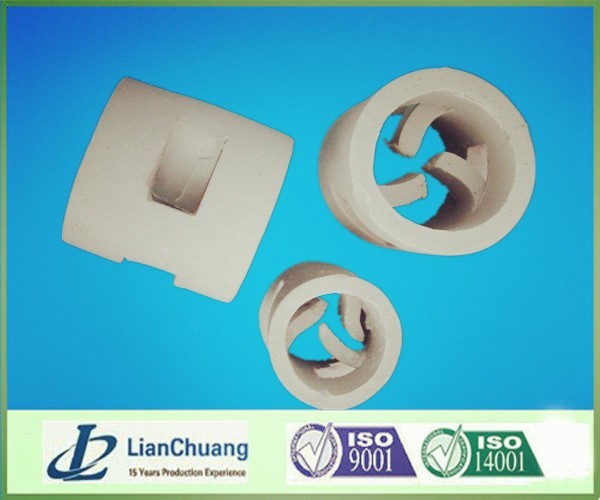

ceramic lessing rings are a packing designed basically from the raschig ring with partitions inside to increase the surface and enhance the transfer efficiency. It is usually used extensively for the supporting packing at the bottom of tower. Ceramic lessing ring has high desity and excellent heat and acid resistance and it withstands the corrosion of various inorganic acid, organic acid and organic solvents except fo hydrofluoric acid. Ceramic lessing one ring as an important heat transfer media, used in the heat transfer system, regenerative oxidisers system (RTO ).

Product specifications

Size | D*H*T(mm) | Bulk density (kg/m3) | Number per | Surface area (m2/m3) | F factor m-1 |

2”(50mm) | 50*50*5 | 600 | 6400 | 145 | 565 |

3”(80mm) | 80*80*5 | 820 | 1950 | 120 | 356 |

4”(100mm) | 100*100*10 | 850 | 1000 | 110 | 252 |

5”(120mm) | 120*120*12 | 860 | 370 | 75 | 146 |

6”(150mm) | 150*150*15 | 980 | 295 | 60 | 101 |

Note:

Two types are supplied: Ceramic cross; Ceramic cross coated with glaze.

Size: 8mm-150mm ( uncommon size can be customized if you require )

Chemical Analysis of Ceramic Lessing Rings Packing :

Item | Unit | Data |

Al2O3 | % | 23-30 |

SiO2 | % | 62-70 |

Fe2O3 | % | <1< span=""> |

CaO+MgO | % | <1< span=""> |

K2O+Na2O | % | <4< span=""> |

The others | % | <1< span=""> |

Advantage:

1. Excellent raw materials for production

2. Internal and external quality control

3. Trouble-free reactor filling due to high crush strength

4. Different common sizes are available, uncommon sizes can be customized as your request.

5. large fluid capacity & large void space & excellent acid/heat resistance

6. ISO9001:2008 certificate

7. 10 years’manufacture experience