Product Description

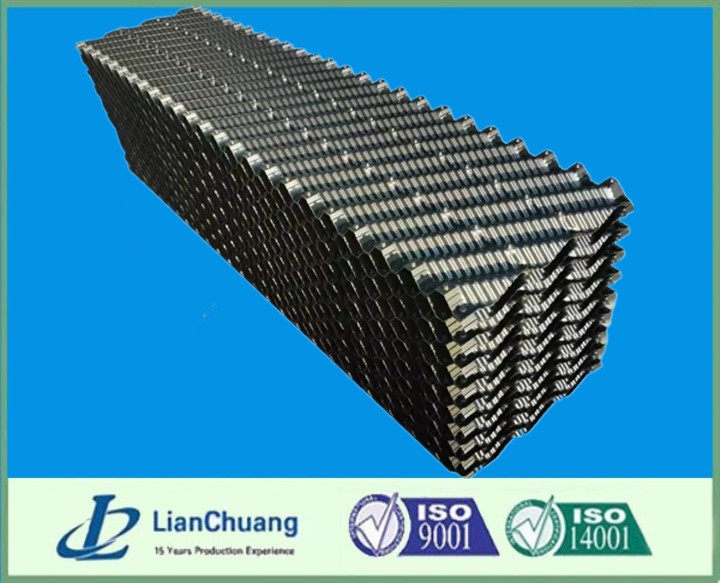

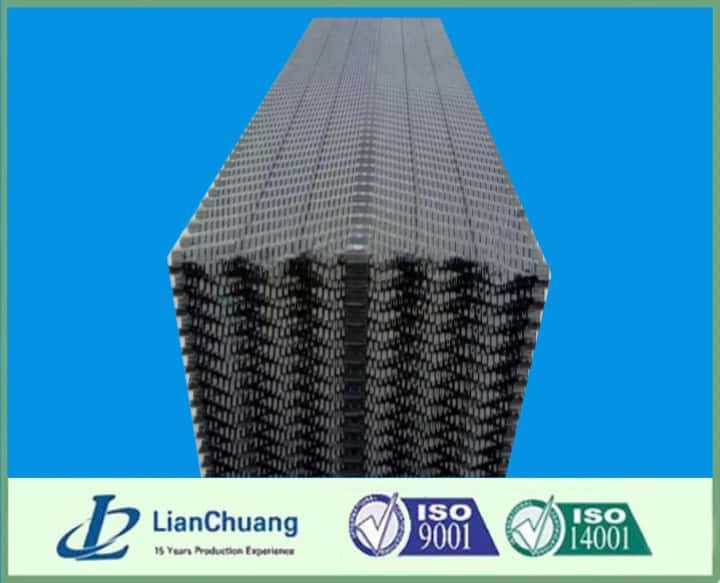

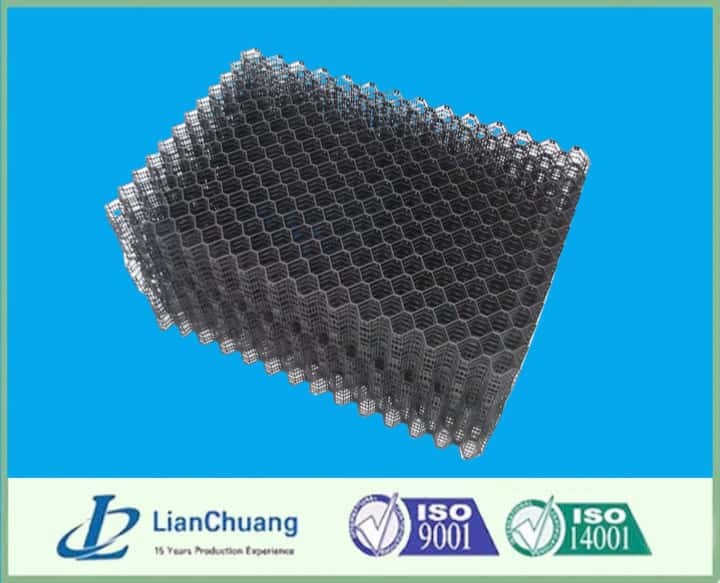

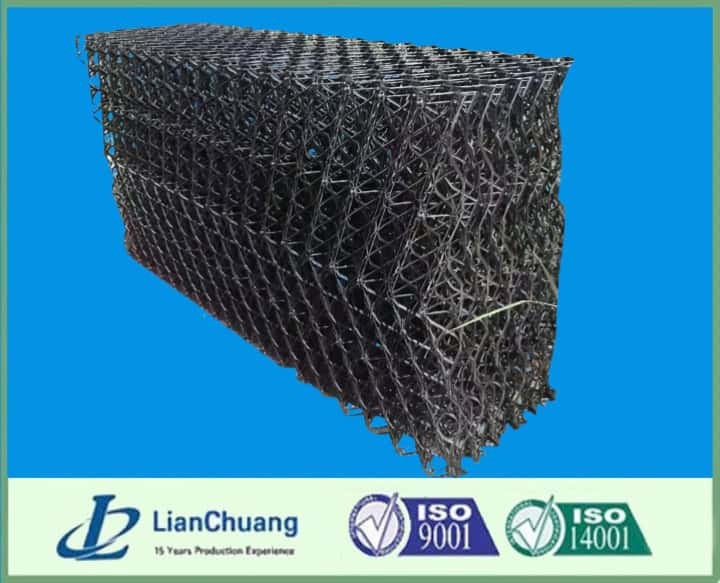

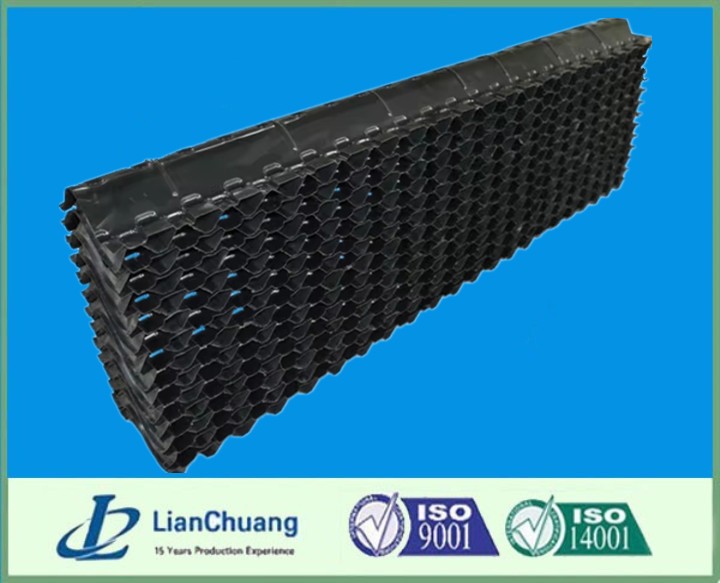

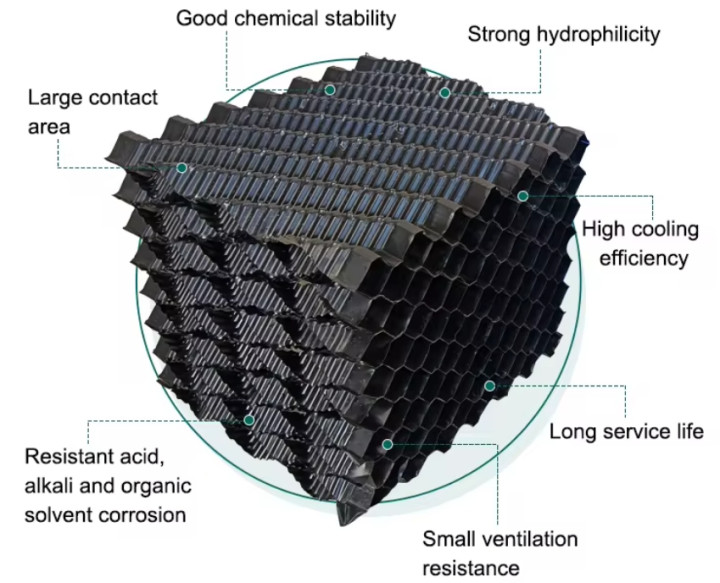

The operational principle of Cross Fluted Cooling Tower Film Fill is to maximize the contact between water surface area and air for the longest time possible. Film fills enable water to form thin, flowing sheets, maximizing the water surface area exposed to the interacting airflow.

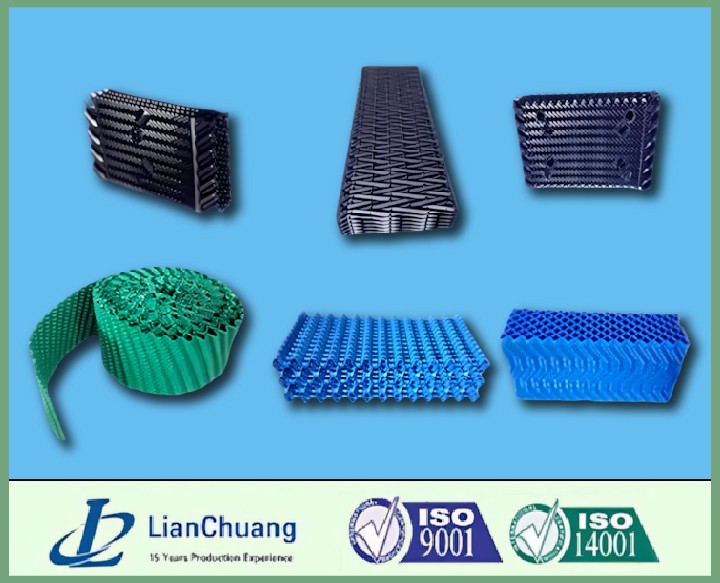

Cooling tower sheet film fills, or media, come in various forms and microstructures, each tailored to specific applications. Film fills are chosen for direct replacement, performance enhancement, and compatibility with water conditions. Each cross fluted cooling tower fill has unique performance characteristics suitable for different heat loads, flow rates, water qualities, and horsepower requirements.

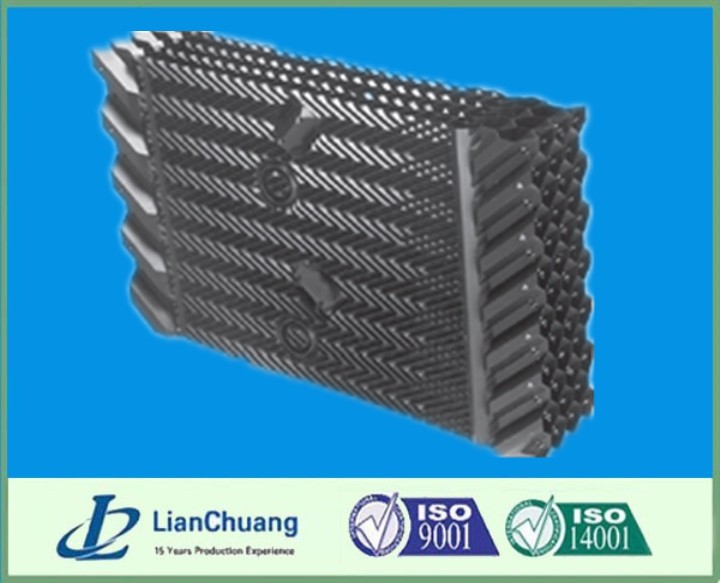

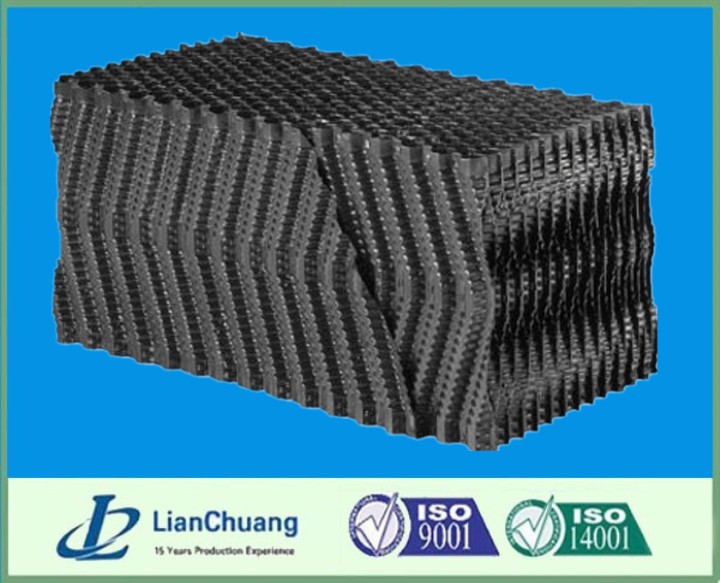

Cross-fluted cooling tower fills improve water distribution by dividing the water stream as it travels through the fill pack. To achieve superior thermal performance and minimal pressure drop, these fills feature advanced flute and microstructure designs, along with strict fabrication standards. PP PVC cross fluted cooling fill designed for high thermal efficiency, the alternating fill sheets facilitate excellent lateral water dispersion. Available for crossflow applications, these fills are ideal for industries such as power, refining, chemical, and food processing, provided the water quality is good.

Features of Cross Fluted Cooling Tower Fills:

1. Bonded edges with dedicated bond points for increased strength and durability.

2. Engineered microstructure for enhanced water distribution and thermal mixing.

3. High thermal performance.

4. Proprietary edge trim that directs water to both sides of the sheet.

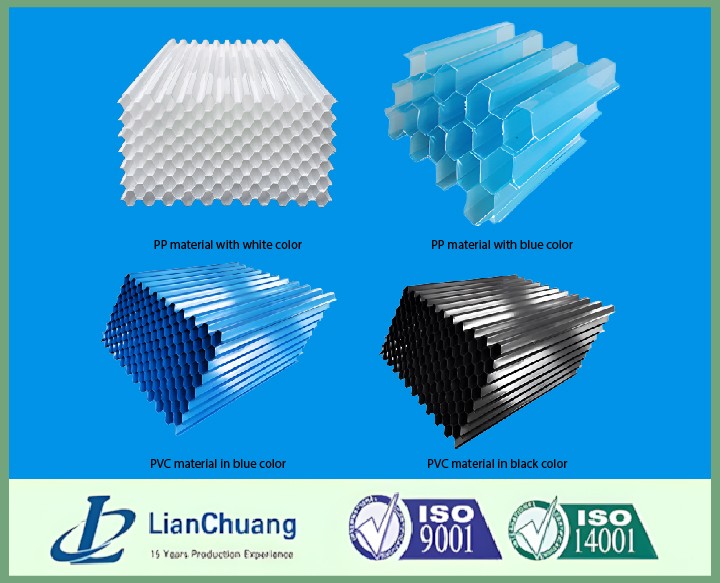

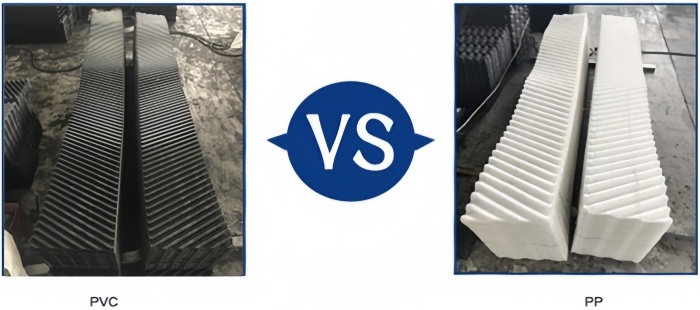

5. Available in standard PVC and HPVC, with mechanically assembled packs available in PP.

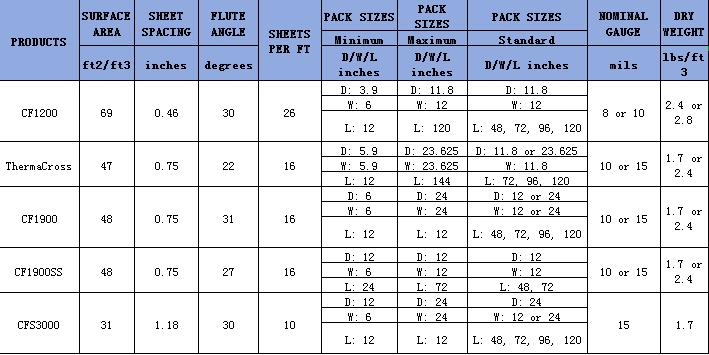

Cross Fluted Cooling Tower Film Fills Specification:

Cross Fluted Cooling Tower Film Fills Applications

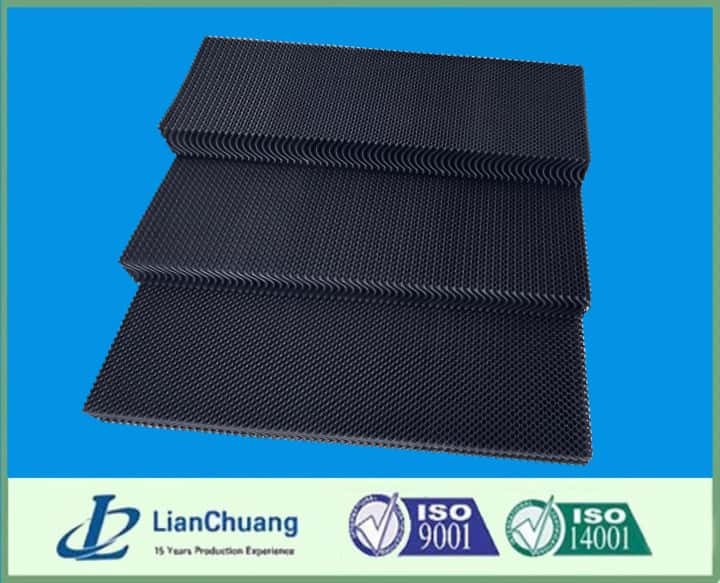

CF1900: CF1900 cross fluted fill is widely favored for both field-erected and factory-assembled counterflow cooling towers and is also suitable for crossflow towers. It is primarily used in HVAC and light industrial applications where water has low concentrations of total suspended solids.

CF1900SS: CF1900SS fills is a high-performance structured packing constructed from 304L stainless steel, designed for specialized applications where extreme temperatures or flammability concerns limit the use of polymer materials. This fully engineered solution features 228 welds per cubic foot (8050/m3), ensuring precise sheet uniformity and consistent packing dimensions.

CF1200: CF1200 is designed for factory-assembled counterflow towers (suitable for HVAC and light industrial applications) and can serve as a distribution pad with depths of 3.9” (100 mm) and 5.9” (150 mm) in systems where water contains very low levels of total suspended solids. Beveled tips enhance drainage to minimize pressure drop.

CFS3000: Used in the same applications as CF1900, the CFS3000 model has larger channels, reducing fouling risk when handling water of lower quality.

Package of PVC Cross-flute Fills:

Package: In bundle, or by pallet, or by wooden box, or as per customer's specific requirement.