Product Description

Name | |

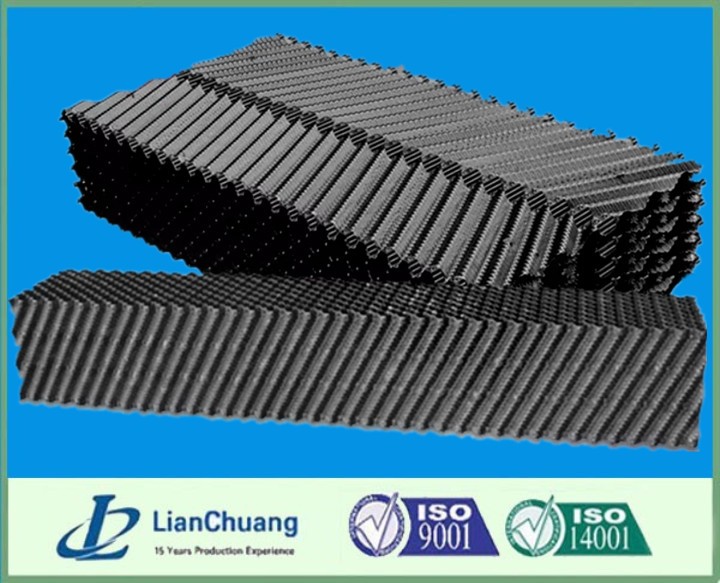

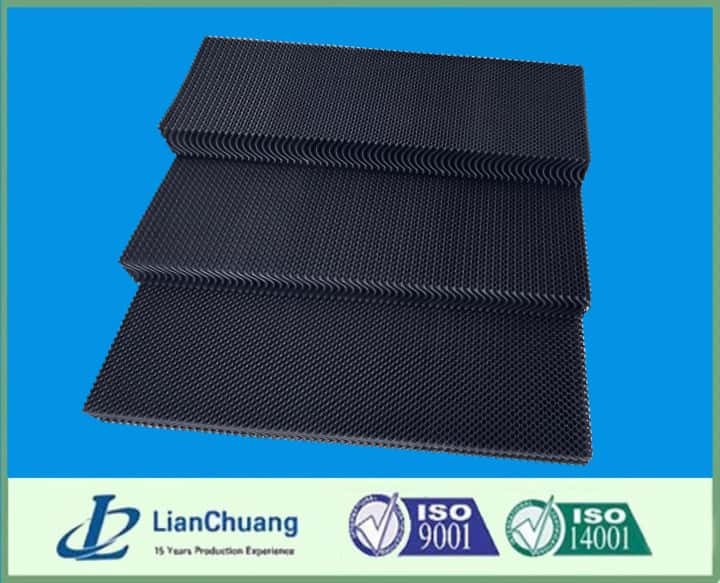

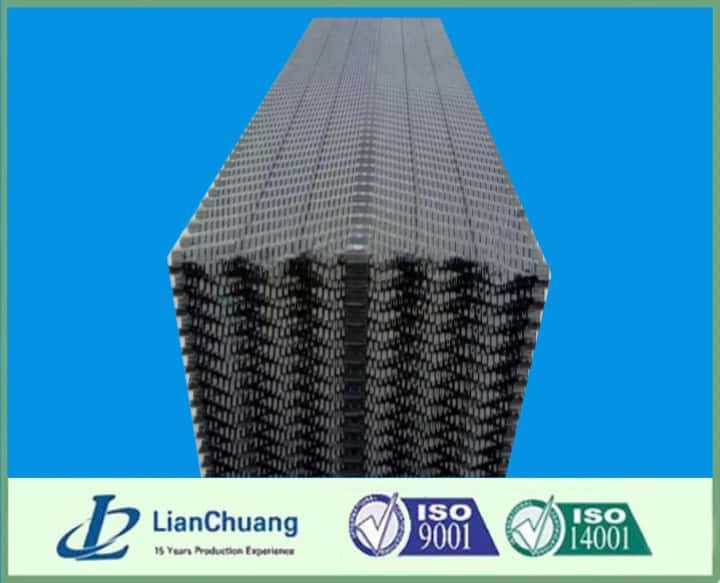

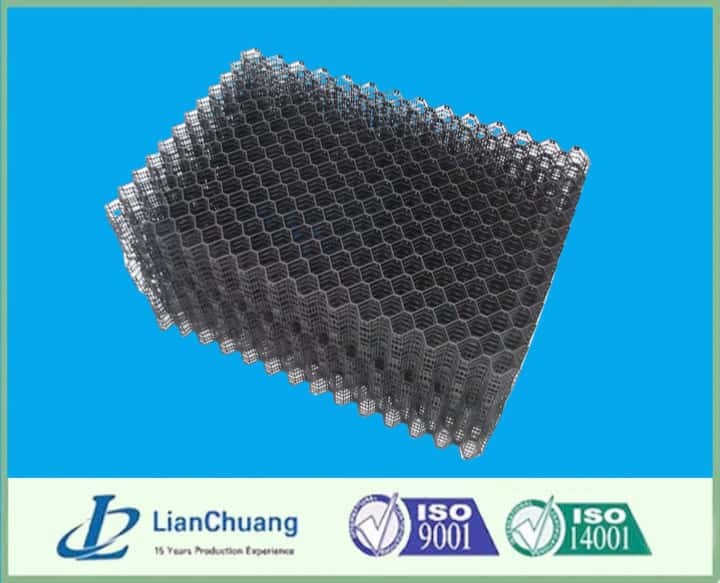

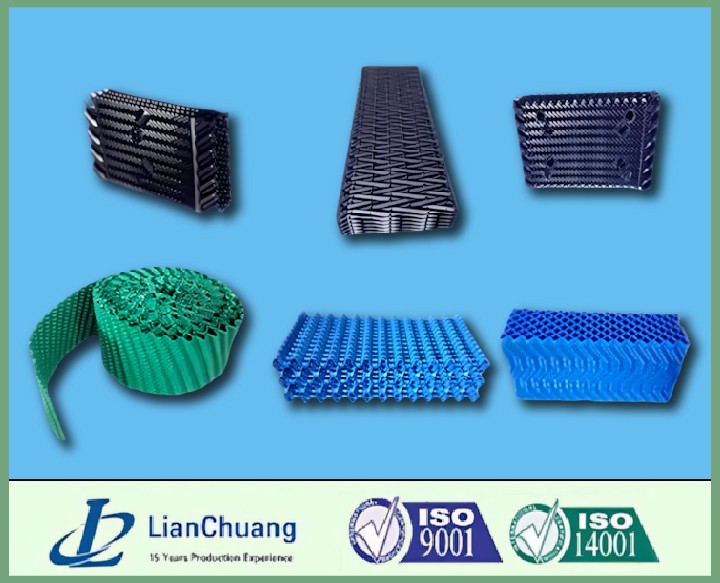

Type | Crossflow and Counterflow cooling tower filler |

Unit | Piece or block |

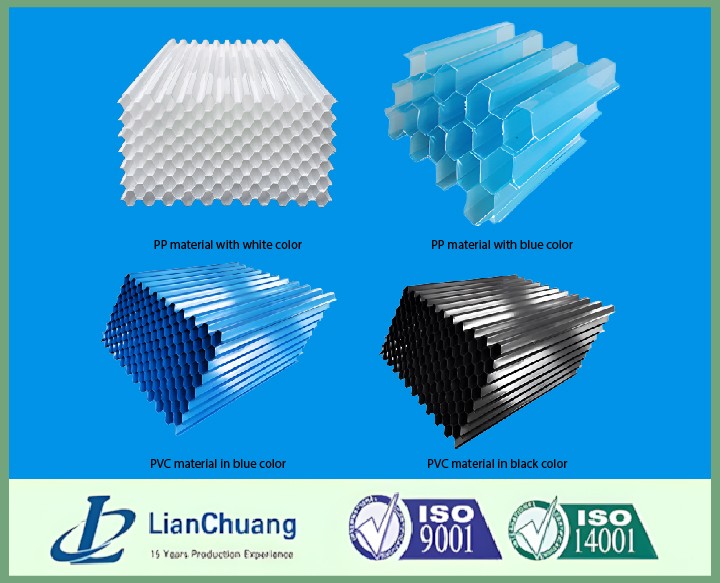

Material | PVC PP |

Usage | For cooling tower to cooling the water |

Width | 150mm, 305mm,610mm |

Length | 1200mm, 1800mm, or Customized |

Pitch | 12mm, 15mm, 19mm, 25mm |

Thickness | 0.25mm-0.6mm |

Color | Black Green or White |

Shaping mode | moulded and large plastic blister |

Minimum Order: | 100 PCS |

Packaging Details: | In bundle,wooden pallet or as your request |

Supply Ability: | 10000 piecess/month |

Production date: | Within 7-10 days after your payment arrived |

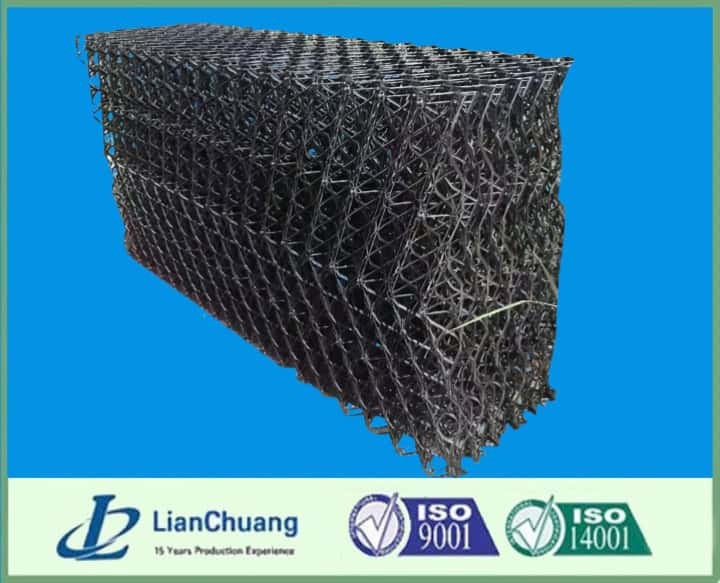

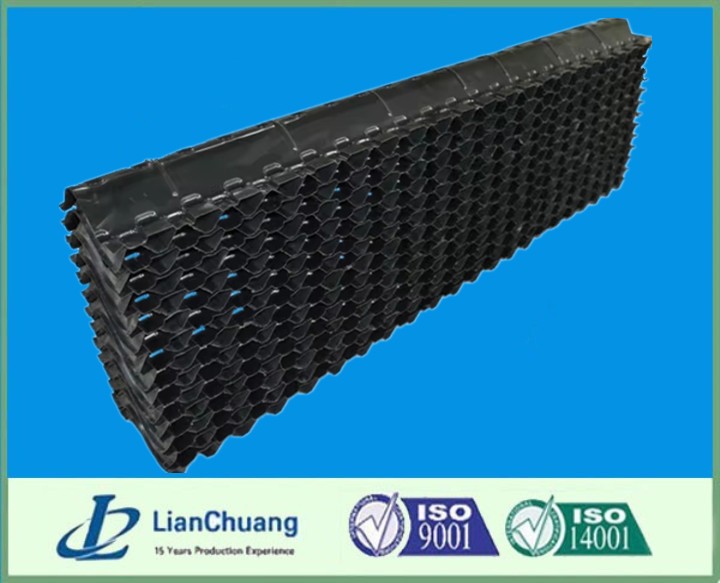

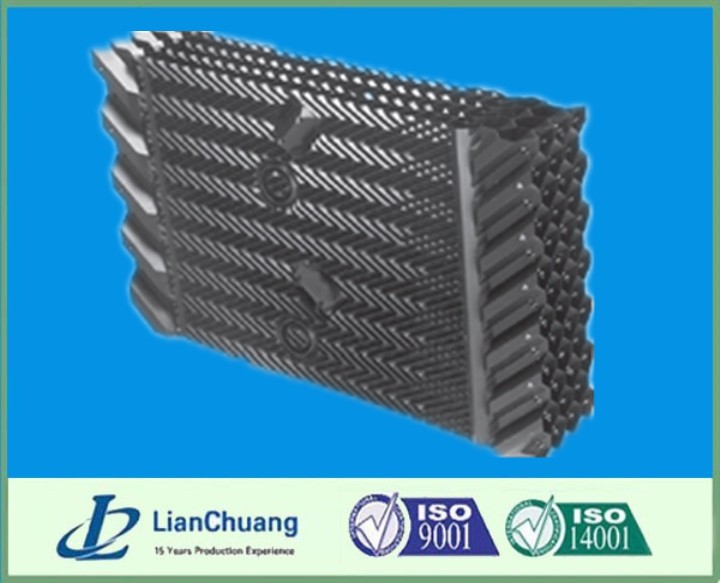

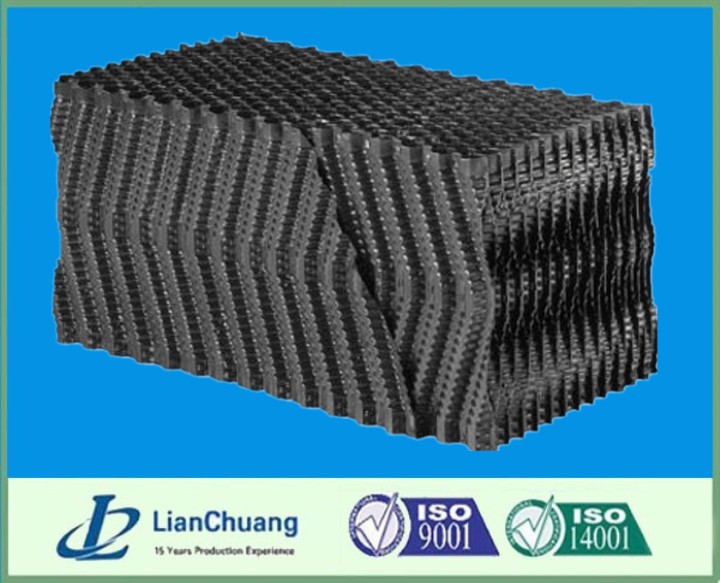

Oblique wave cooling tower fill, a type of counterflow cooling tower fill, is assembled into a block and positioned at the bottom center of the tower. Oblique wave cooling tower fill can be used in both counterflow and crossflow cooling tower applications.

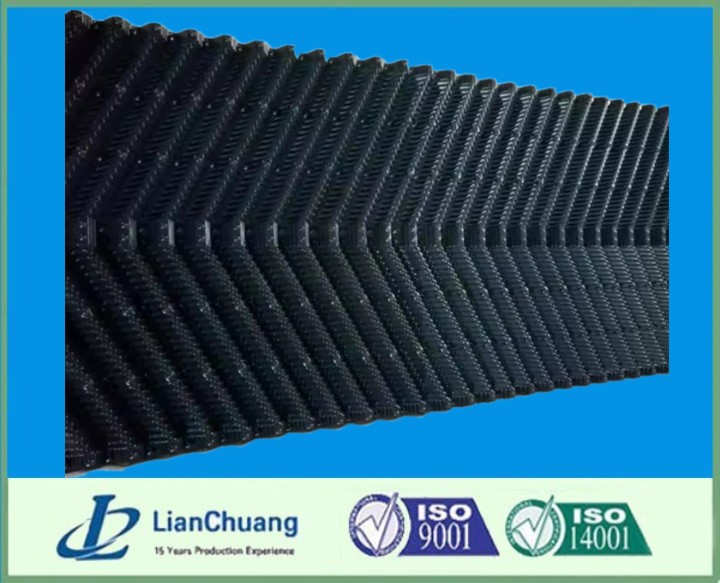

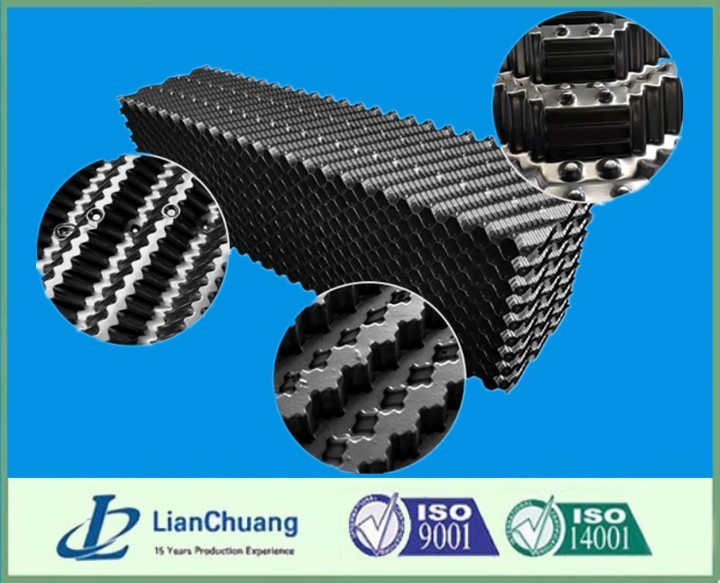

The thickness of oblique wave cooling tower fill ranges from 0.25mm to 0.6mm, with widths of 150mm, 305mm, and 610mm. Available lengths include 1200mm, 1800mm, 2000mm, and 2400mm. Pitch distances are 12mm, 15mm, 19mm, and 25mm, with 19mm being the standard size. PVC air inlet louvers that match the CF1900 fill ensure that the water treatment surface area reaches 248m2/m3, and the typical face velocity is between 2.0 and 3.5 m/s.

The oblique wave cooling tower fill is a highly efficient cooling solution designed for industrial and commercial cooling applications. Its key feature is the oblique wave fill, which maximizes the contact area and duration between water and air, thereby enhancing cooling efficiency while lowering energy consumption and maintenance costs.

Own factory.Can produce high quality of the PVC filler in different sizes, colors and designs.

Characters of oblique wave cooling tower fill:

1. Acid proof

2. Alkali-resisting

3. Anticorrosion for the organic solvent

4. Good performance of inflaming retarding

5. Increasing cross-sectional area

6. Add water retention time

Key Advantagesof Oblique wave cooling tower fill:

1.Maintains original performance to ensure the lowest system operating costs.

2.Minimizes downtime.

3.Provides maximum service life.

4.Ensures operational safety.

5.Simplifies maintenance.

6.Facilitates easy cleaning.

Application:

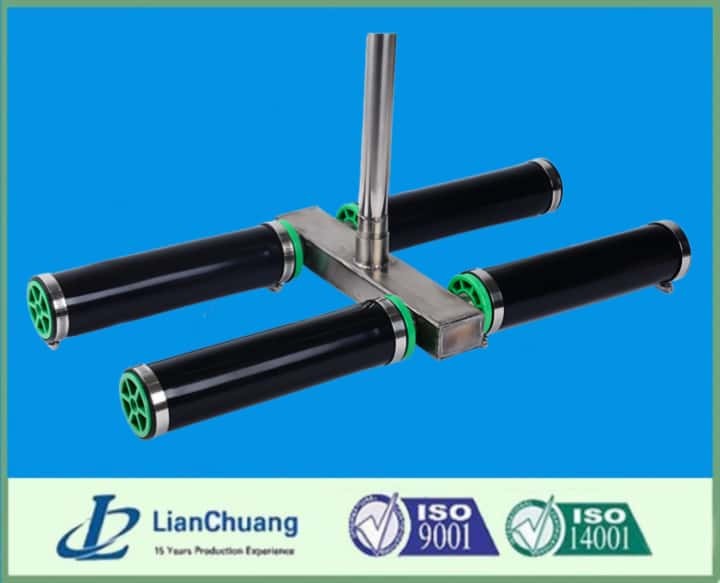

Mainly used in air conditioning cooling system, frozen series, injection molding, leather, foam, power generation, steam turbine, aluminum processing, air compressor, industrial water cooling and other fields.

Package and shipping:

Why choose us:

1. Superior Quality:We are a manufacturer that uses imported raw materials, ensuring outstanding quality at an affordable price.

2. Highly Competitive Pricing:We can adjust prices according to market demands and offer promotional activities even during tough economic times.

3. Expertise:We specialize in production and sales, incorporating advanced development methods and efficient handling processes.

4. Exceptional Service:We respond to emails and resolve questions promptly, ensure timely delivery, and keep you updated. Trust, quality, and excellent service form the foundation of our long-term business relationships.