Product Description

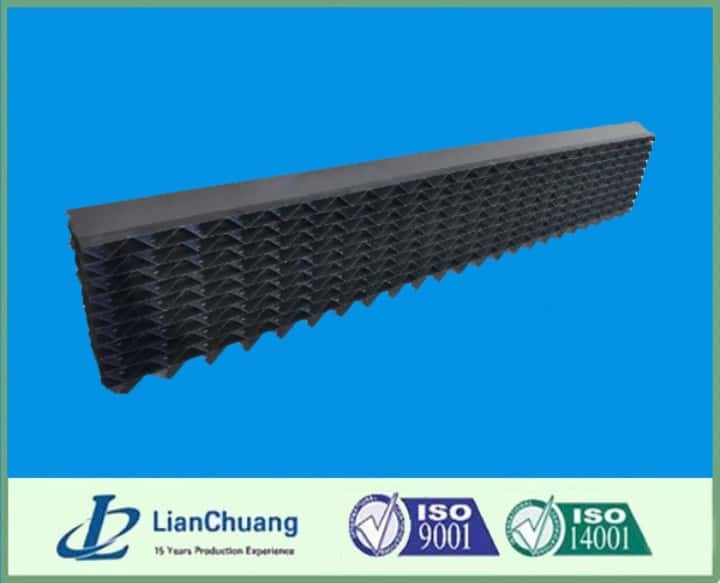

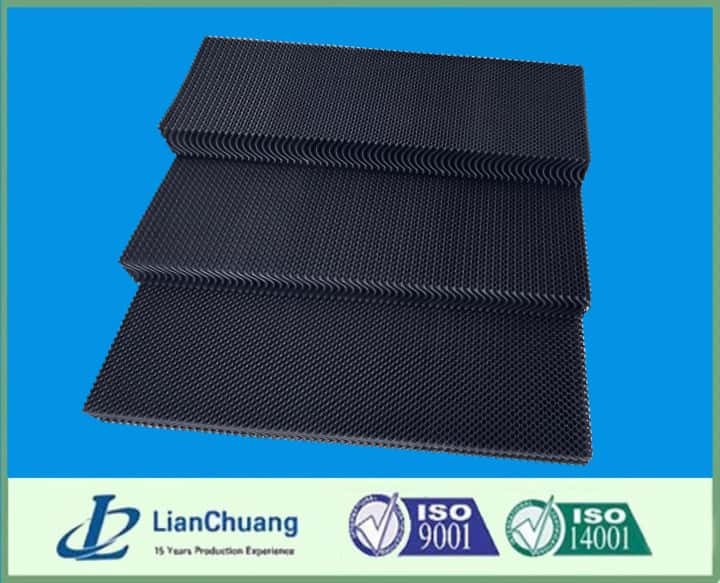

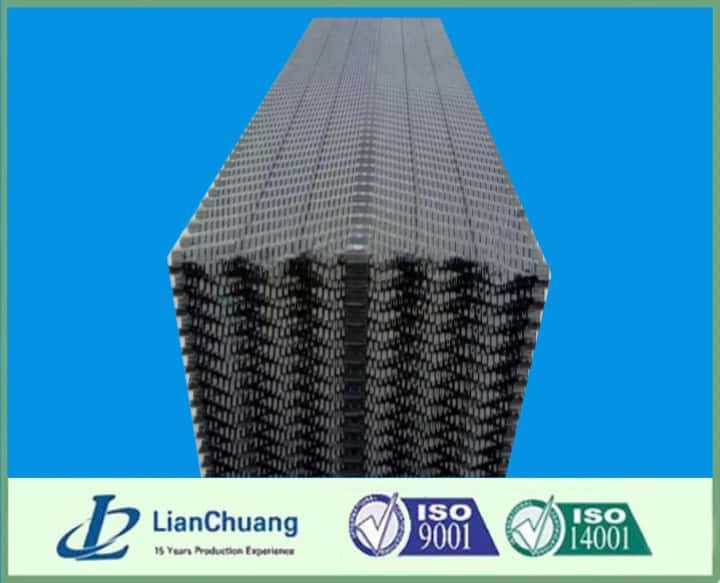

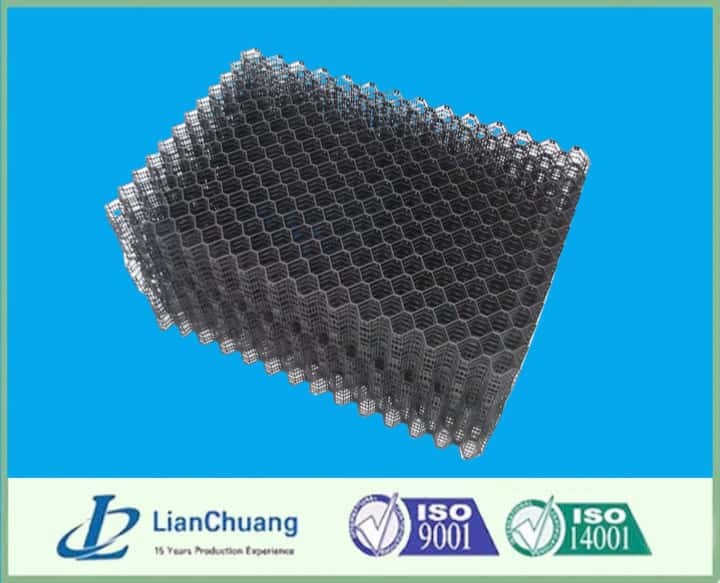

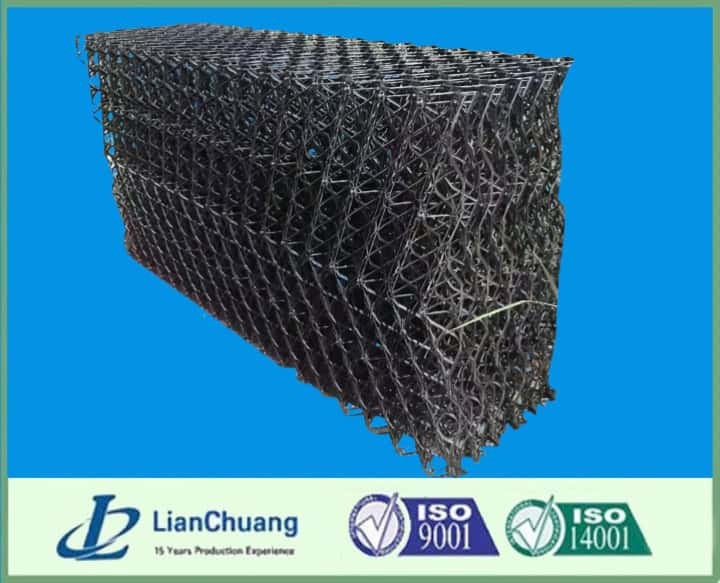

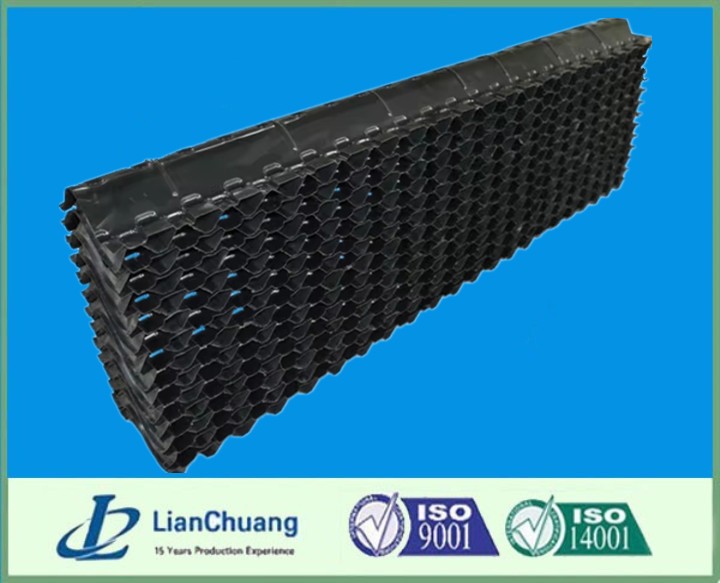

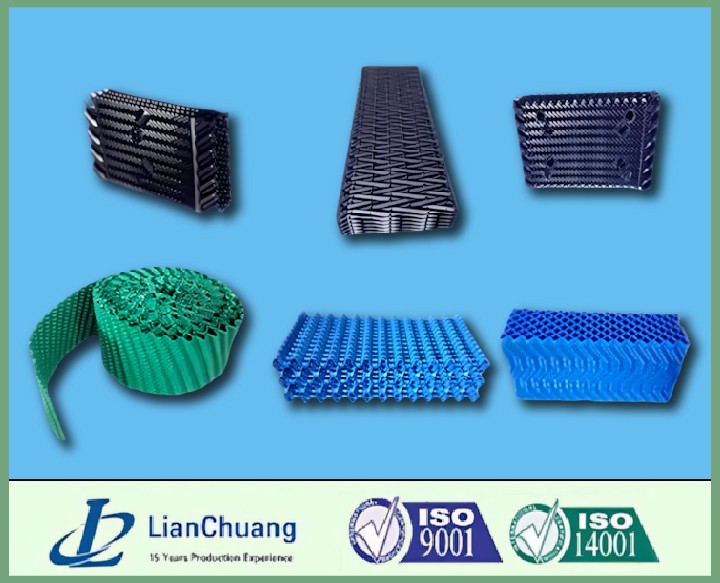

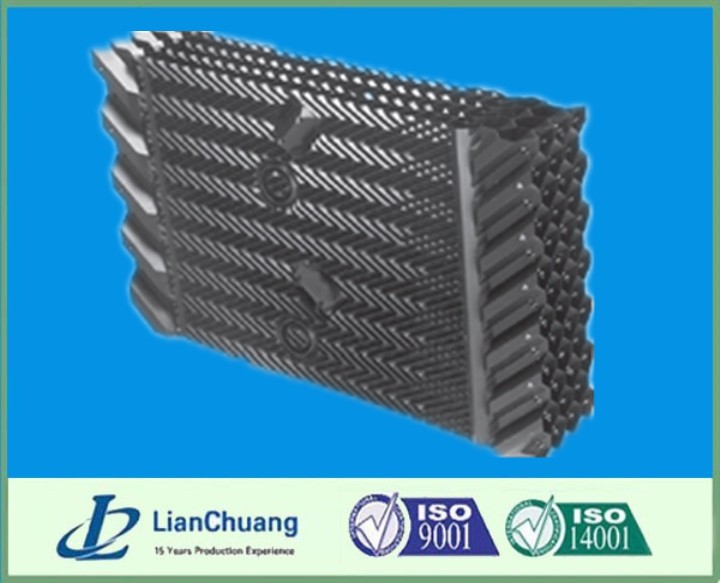

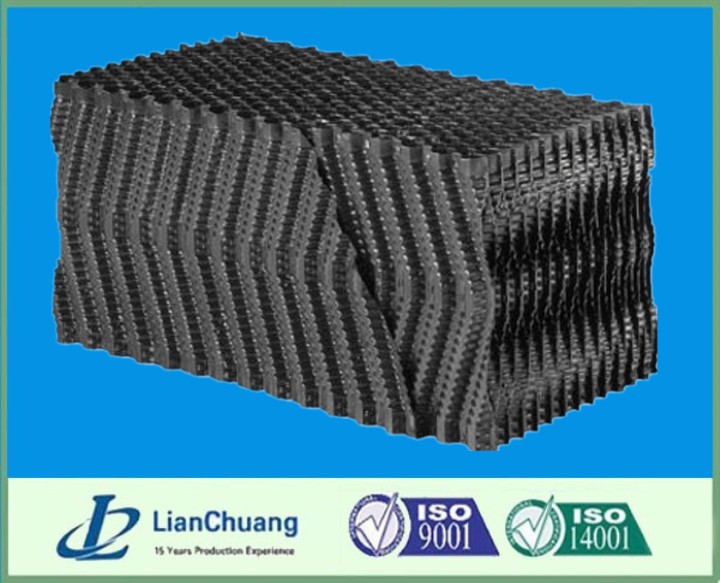

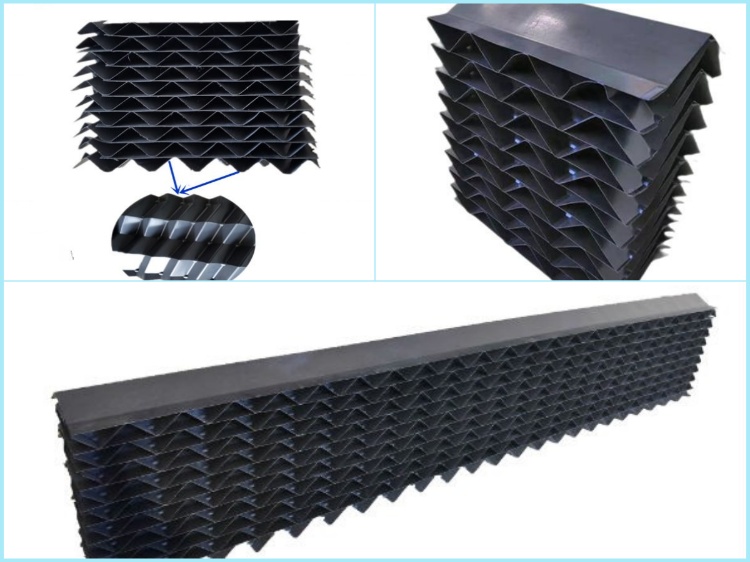

XCEL TU12C Cellular PVC Drift Eliminator for Cooling Tower XCEL TU12C Cellular PVC drift eliminator for Cooling Towers is an advanced design that meets or exceeds the stringent drift emission requirements without increasing fan horsepower. A critical factor in its effectiveness is the exhaust angle, requiring different designs for crossflow and counterflow cooling towers.

Tests show that air direction from the eliminator is vital, and an imperfect design can increase fan load, reducing tower performance. The crossflow version includes a drainage channel to return trapped drift water to the wet side. The XCEL eliminator typically achieves a drift rate of 0.0005% of total flow, with even lower rates possible depending on the tower's configuration.

Key Features:

- High-Performance Drift Elimination: The XCEL TU12C is engineered to efficiently reduce drift and water loss in counterflow cooling towers, significantly improving system performance and water conservation.

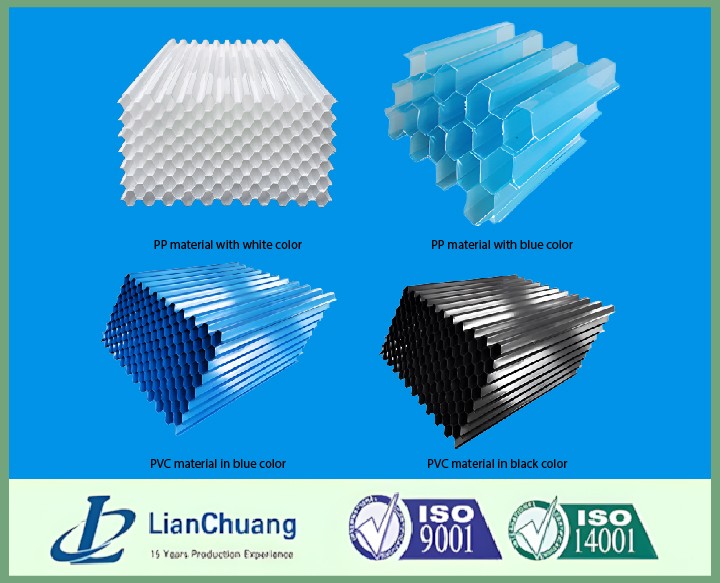

- Durable Cellular PVC Construction: Made from high-quality cellular PVC, the TU12C drift eliminator is resistant to corrosion, UV degradation, and wear, making it ideal for long-term use in demanding conditions.

- Easy Installation & Maintenance: The drift eliminator is designed for easy installation and maintenance, helping to reduce downtime and maintenance costs, ensuring smooth operation and longevity.

Benefits of Xcel Tu Drift Eliminator:

- Increased System Efficiency: By preventing drift, the TU12C helps maintain the optimal performance of the cooling tower, reducing water wastage and improving energy efficiency.

- Enhanced Durability: The cellular PVC material is resistant to chemicals, heat, and environmental stress, ensuring the longevity of the product even in challenging conditions.

- Cost-Effective Solution: With its durable construction and efficient performance, the XCEL TU12C offers a cost-effective solution for industries that rely on cooling towers for their operations.

With its low drift rate and pressure drop, the XCEL TU12C is one of the most efficient drift eliminators available. Drift eliminators should be cellular, specifically the Marley XCEL TU model or an equivalent recognized product. Made from 17 mil (0.017 inches) PVC, the eliminator is thermoformed to provide at least three changes in air direction and welded into sheet-like components. The material’s flame spread rating must not exceed 25, per ASTM E-84 standards. The XCEL TU12C Drift Eliminator is a reliable, long-lasting solution for drift reduction and enhancing water treatment efficiency in industrial cooling towers.