Product Description

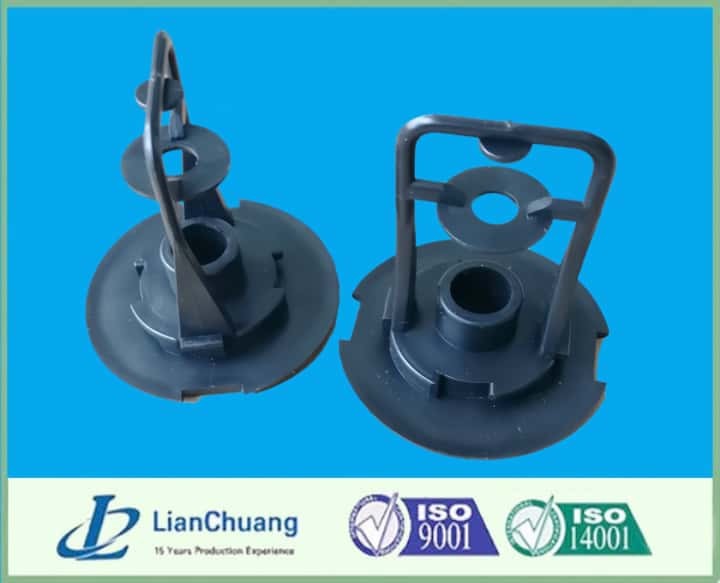

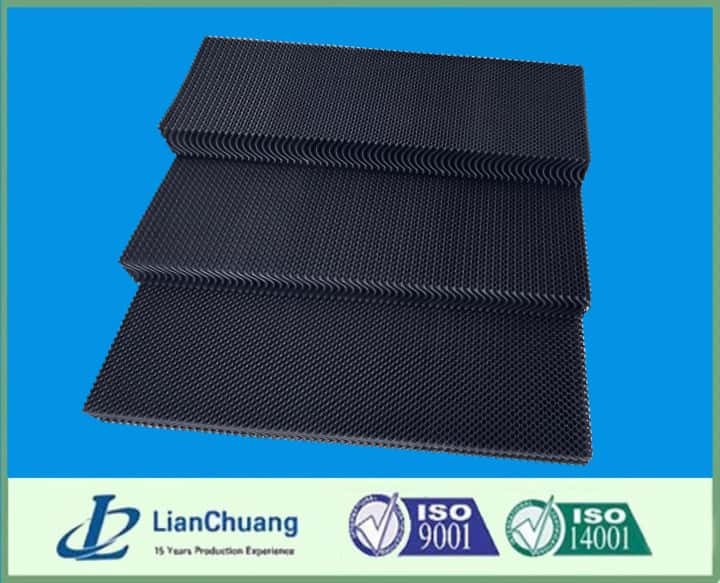

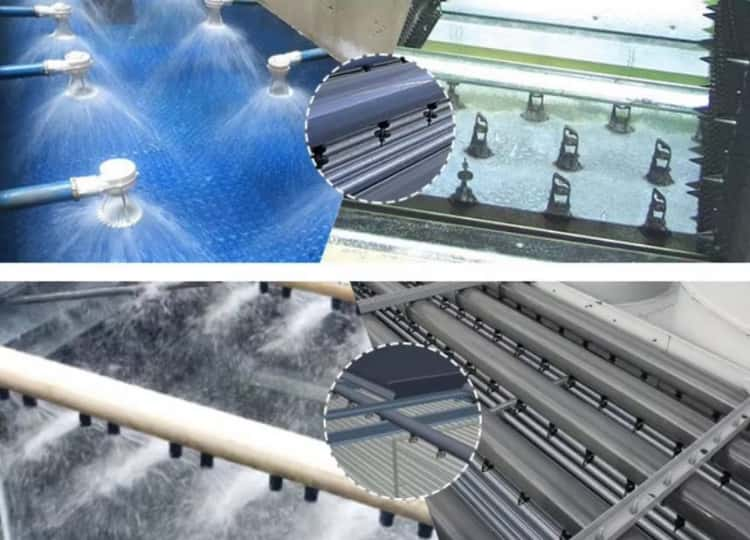

XF Crossflow nozzles are advanced water distribution components engineered to optimize the performance of cooling towers, closed-circuit fluid coolers, and evaporative condensers. These nozzles are designed to meet the demanding needs of industrial cooling systems, particularly for crossflow cooling towers. xf crossflow spray nozzles ensure uniform water distribution over the cooling tower fill media, enhancing heat exchange efficiency and maximizing cooling performance. Made from highly corrosion-resistant materials, XF Crossflow nozzles are capable of withstanding harsh operating environments.

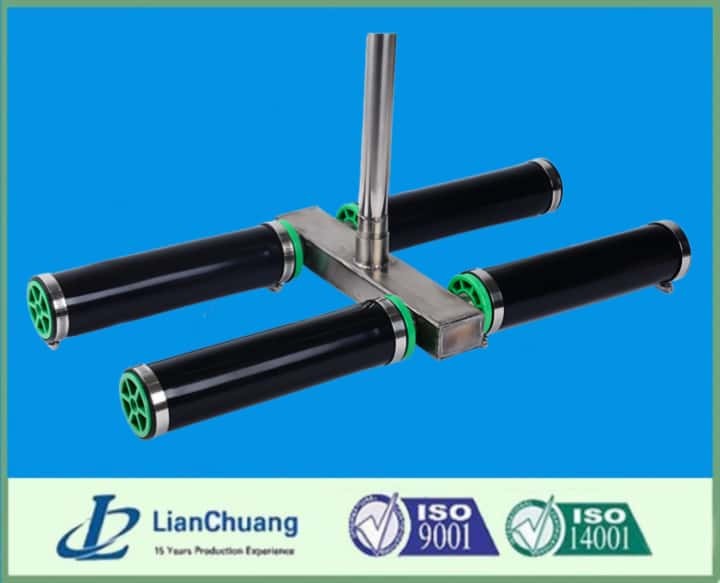

We offer two types of distribution systems for cooling towers, closed-circuit fluid coolers, and evaporative condensers to maximize system performance: pressurized and gravity-feed systems. Both systems feature large orifice, non-clogging nozzles that ensure effective wetting of the heat transfer surface.

Features of XF Series Spray Nozzles:

- Ease of Maintenance: Simple to maintain with user-friendly design.

- Snap-in/Out Grommet Design: Easy installation and removal.

- Large Non-Clog Orifice: Prevents blockages for continuous performance.

- Robust, Durable Construction: Built to last, even under demanding conditions.

- Universal Alignment: Flexible installation and use in various systems.

- Anti-Scale Design: Reduces scale build-up for long-term reliability.

- No Moving Parts: Minimizes wear and tear, reducing the need for maintenance.

- Eliminates Dry Spots: Ensures complete coverage, avoiding dry areas that can reduce efficiency.

- EAC 360™ Spray Nozzle: Easily replaceable for quick repairs or upgrades.

- High Operating Temperature Range: Suitable for temperatures from 120°C to 300°C.

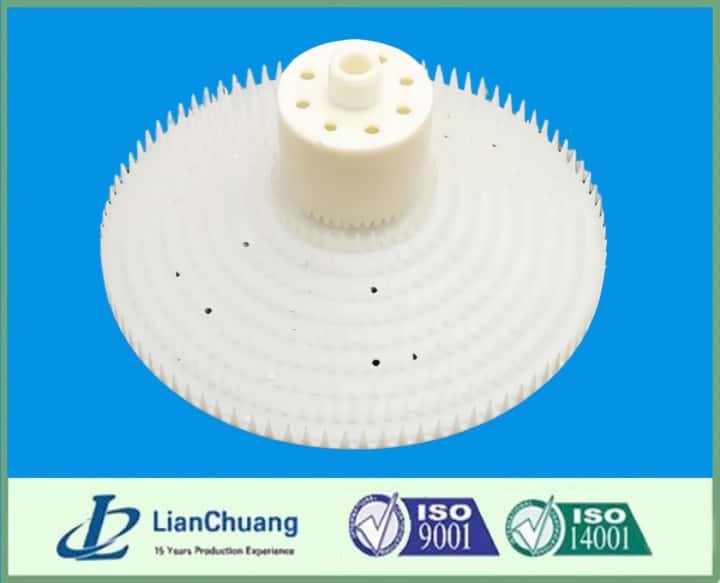

- Optimized Flow Circulation: Improves turbulent flow and optimizes solution mixing.

- Uniform Solution Mixing: Ensures consistent solution quality and improves overall product quality.

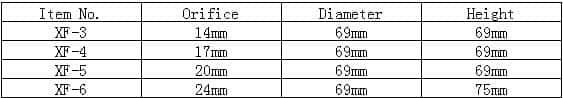

XF Crossflow Nozzle Models:

The XF Crossflow nozzles come in four models, each designed for specific applications. The different models are identified by their nozzle diameter:

- XF-3: 14mm diameter

- XF-4: 17mm diameter

- XF-5: 20mm diameter

- XF-6: 24mm diameter

The height of the XF-3 to XF-5 models is consistent at 69mm, while the XF-6 model has a height of 75mm. These varying diameters allow for flexibility in system design, ensuring optimal performance for a wide range of cooling systems.

XF Crossflow Nozzle Applications:

XF Crossflow nozzles are ideal for a variety of industrial applications, including:

- Plating tanks

- Cleaning tanks

- Phosphating tanks

- E-coat tanks

- Fertilizer tanks

- Pulp tanks

- Sludge tanks

- Paint booths

- Anodizing tanks

- Cooling towers

These nozzles are highly versatile, providing superior water distribution and ensuring consistent performance in diverse industrial settings. Whether you're managing a cooling tower or a specialized tank, XF Crossflow nozzles deliver enhanced efficiency, reliability, and durability.