Product Description

Multi-Layer Ceramic RTO Media from represents a comprehensive solution for enhancing the performance and efficiency of regenerative thermal oxidizers. By integrating this advanced media, facilities can optimize their operations, reduce costs, and improve environmental compliance.

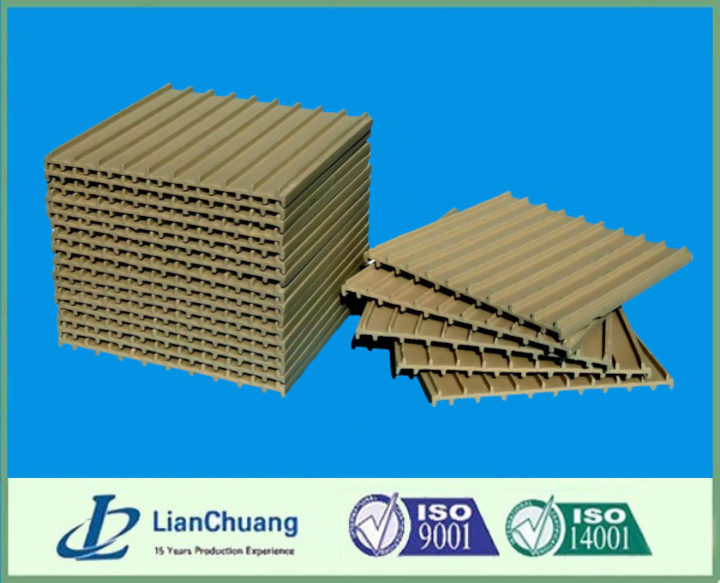

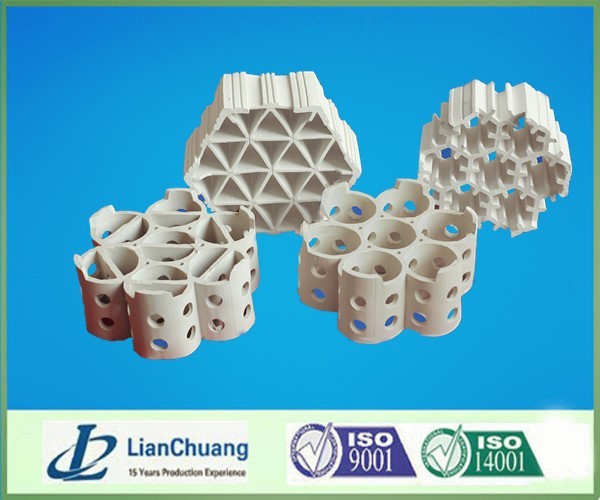

Products introduces multi-layer ceramic media, a cutting-edge solution designed to enhance the efficiency of regenerative thermal oxidizers (RTOs). Available in various configurations—including MLM-125, MLM-125-I, MLM-160, MLM-180, MLM-200, and MLM-S—Multi-Layer Ceramic Media can be tailored to meet specific operational needs, whether that involves maximizing thermal efficiency, minimizing pressure drop, or reducing bed height.

Superior Design and Performance

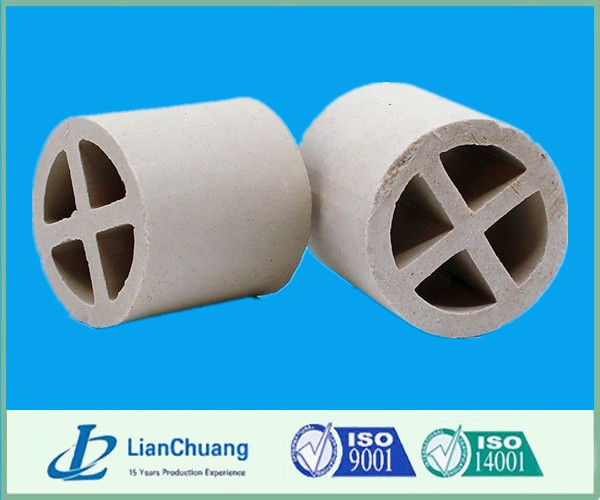

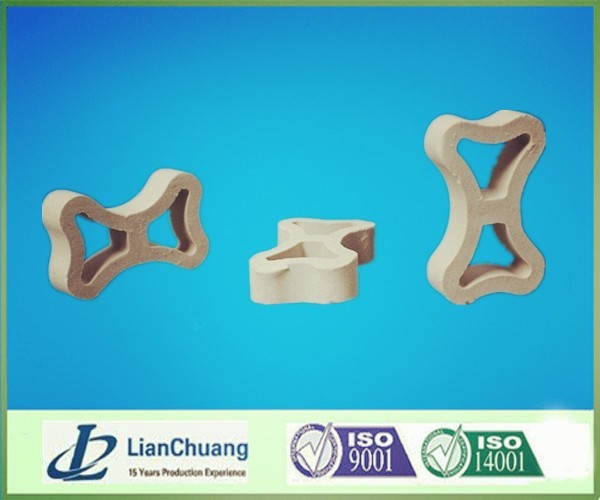

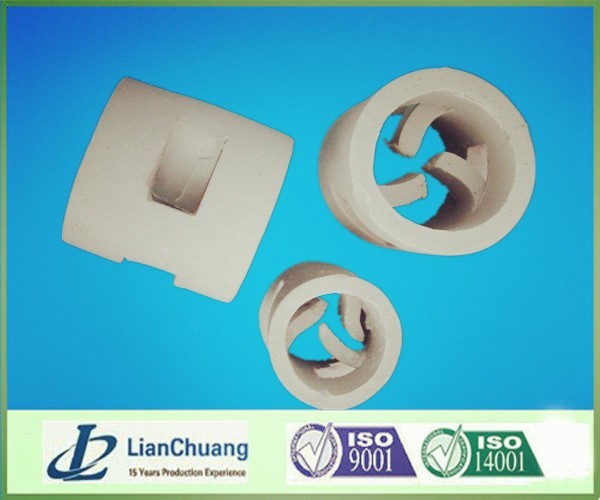

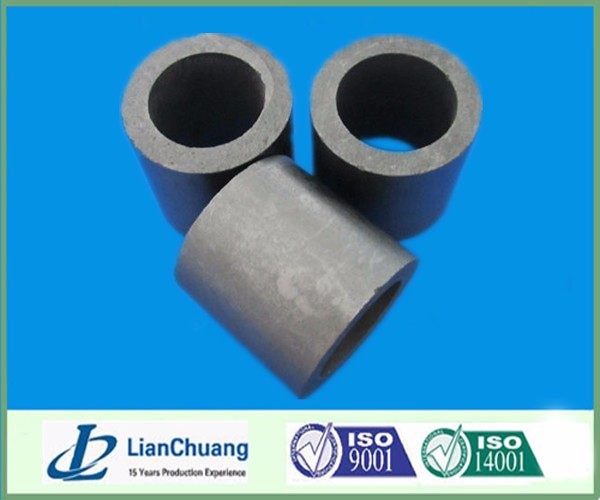

The innovative parallel-plate structure of Multi-Layer Ceramic Media offers significant advantages over traditional packing materials. By incorporating over three times more ceramic material per cubic foot compared to saddles, Multi-Layer Ceramic Media maximizes surface area while minimizing air resistance. This unique design results in high heat capacity and rapid heat transfer, leading to a combination of low pressure drop and exceptional resistance to plugging by particulates.

When using MLM-S instead of traditional 1-inch saddles, the heat recovery beds can be approximately 50% shorter, which translates to reduced original equipment costs. The ability to operate at high gas velocities also allows for a more compact RTO footprint, facilitating the use of smaller blower motors, less expensive starters, and simplified installation wiring.

Cost Efficiency and Savings

Retrofitting existing RTOs with Multi-Layer Ceramic Media can lead to substantial cost savings by increasing thermal efficiency, reducing fuel consumption, and lowering pressure drops that decrease fan power requirements. Many users experience a payback period of less than six months due to these operational savings.

Moreover, Multi-Layer Ceramic Media enables RTOs to function at gas velocities of up to approximately 400 scfm/ft², achieving excellent heat recovery with moderate pressure drop. This capacity enhancement can often eliminate the need for a second RTO, simply by replacing the media and upgrading the fan.

Enhanced VOC Destruction and Reduced Maintenance

The use of Multi-Layer Ceramic Media significantly improves the VOC destruction efficiency of existing RTOs. By reducing bed depths, the design effectively enlarges the combustion chamber, while lower back pressure minimizes leakage through switch valves.

Maintenance costs are also reduced when using Multi-Layer Ceramic Media in RTOs handling particulate-laden air streams. Traditional random packing media act as efficient particulate filters but often require frequent cleaning or replacement due to plugging. In contrast, the parallel flow channels of Multi-Layer Ceramic Media allow for better passage of particulates, leading to less frequent shutdowns for maintenance.

Key Benefits of Multi-Layer Ceramic Media

- *High Heat Capacity: Enables shorter bed designs.

*Low Pressure Drop: Allows for smaller fans and lower electricity costs.

*Increased Residence Time: Smaller beds lead to improved combustion chamber performance and reduced stack emissions.

*High Operating Velocities: Facilitates capacity increases for existing RTOs.

*Best Plugging Resistance: Exceptional durability against fouling.

*Thermal Breakage Resistance: More resilient than other structured media.

*Standard Warranty: Backed by a 2-year thermal stress warranty.

Specification:

Item | Unit | MLM-125 | MLM-160 | MLM-180 | MLM-200 | MLM-S Type |

Dimension | mm | 305x305x101 | 305x305x101 | 305x305x101 | 305x305x101 | 305x305x101 |

Surface area | m2/m3-ft2/ft3 | 410/125 | 525/160 | 590/180 | 655/200 | 722/220 |

Density | g/cm3 | 2.25-2.35 | 2.25-2.35 | 2.25-2.35 | 2.25-2.35 | 2.25-2.35 |

Weight | Kg/m3 | 703 | 873 | 981 | 1096 | 1052 |

Acid Resistance | % | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

Water Absorption | % | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

Free Space | % | 69 | 61 | 56 | 51 | 54 |

Max Working Temperature | ℃ | 1180 | 1180 | 1180 | 1180 | 1180 |

Heat Capacity | (kJ/m2-°C) | 670 | 810 | 940 | 1070 | 1070 |

Crushing Strength | lb/ft2 | 4210 | 5380 | 6120 | 7340 | 7340 |