Product Description

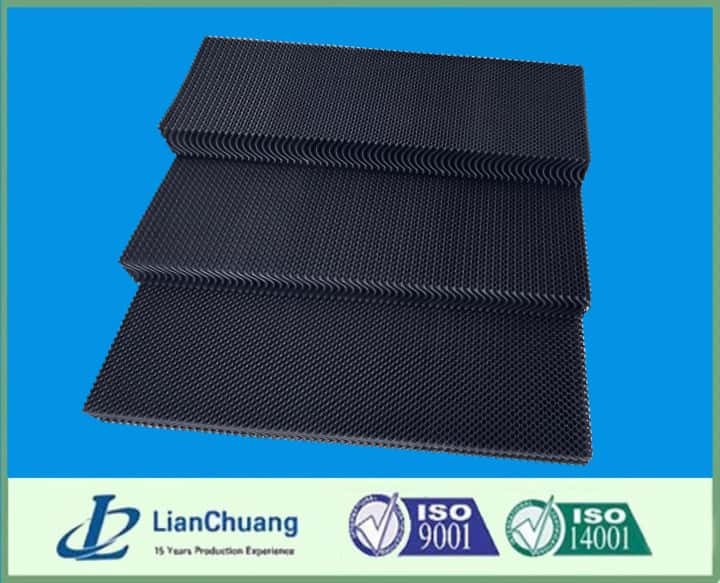

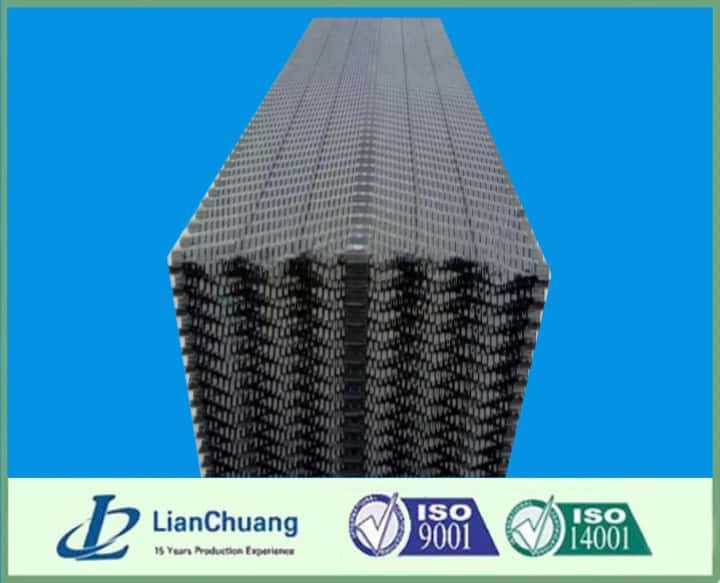

Marley Omega Crossflow Splash Bar Fill is a reliable and efficient solution designed to enhance the performance of crossflow cooling towers. With its versatile design, durable materials, and high thermal efficiency, it is suitable for almost any cooling tower, regardless of manufacturer or age.

Key Features Of Omega Splash Bar Fill

- High Thermal Performance

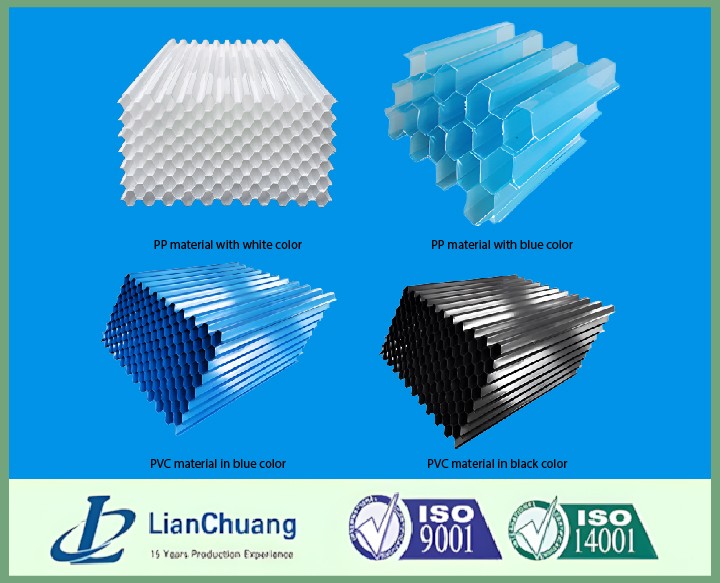

Omega splash bar fill features variable bar spacing that optimizes thermal efficiency while reducing the need for excessive fill material and installation time. The parallel-to-airflow configuration further enhances cooling tower performance by maximizing heat exchange. - Durable, Corrosion-Resistant Materials

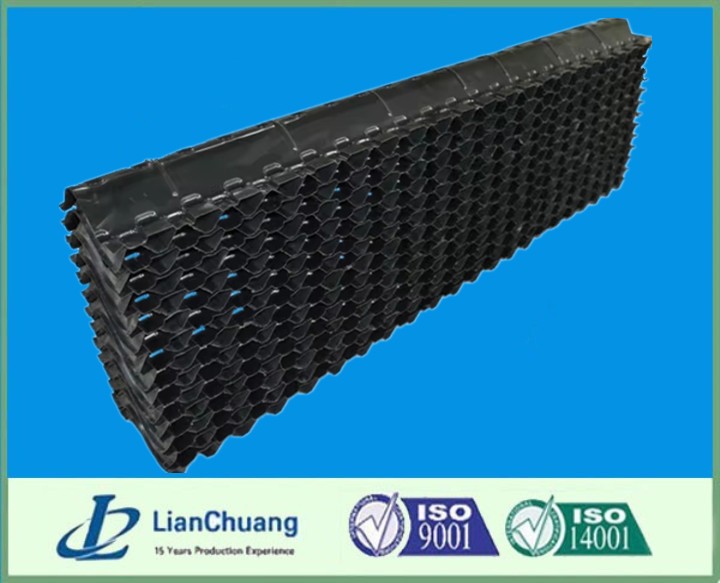

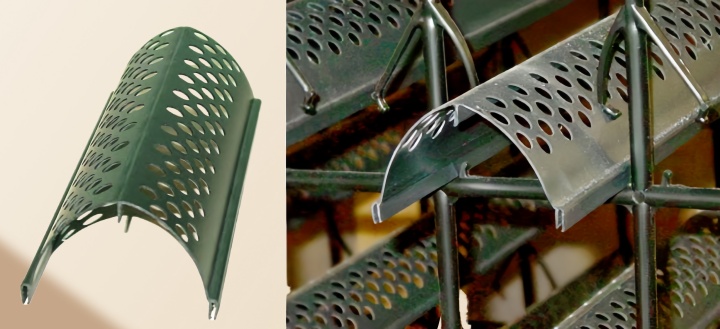

Each Omega fill bar is made from high-quality PVC (polyvinyl chloride), manufactured at SPX’s state-of-the-art plastics facility. This material meets or exceeds CTI Standard 136 for strength, flammability resistance, and impact durability, ensuring reliable performance even in challenging environments. - Innovative Design for Structural Stability

The arched shape of the Omega Fill Bar is specifically engineered to improve structural integrity and prevent sagging, even after prolonged exposure to demanding cooling tower environments. - Secure and Flexible Installation

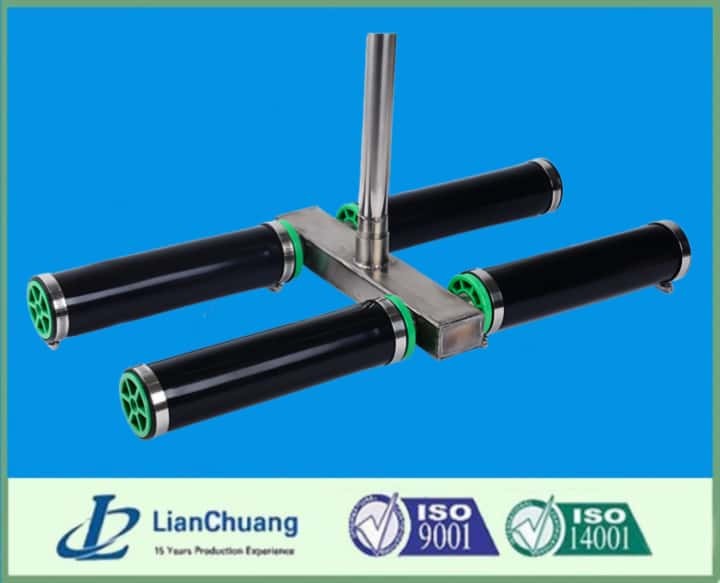

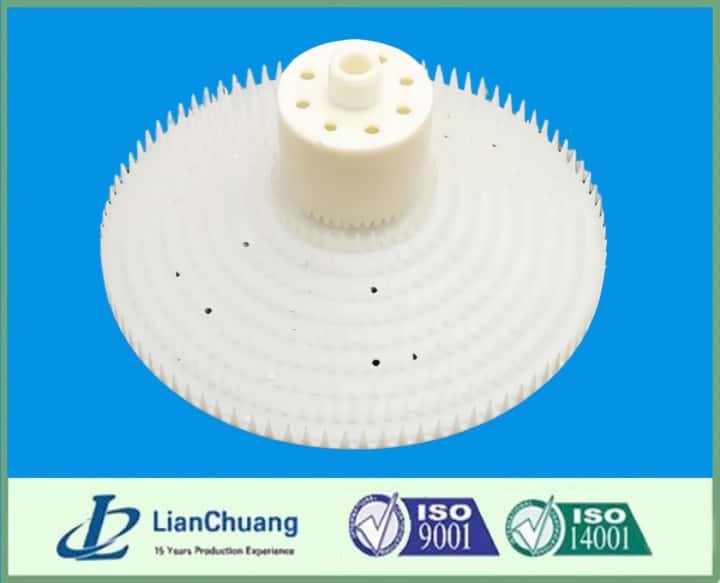

Omega splash fill Bars are securely attached to the Gridloc™ Polypropylene Grid for easy and stable installation. Alternative support options include stainless steel or vinyl-coated wire grids, paired with injection-molded polypropylene benches designed to reduce wear on the fill bars over time. - Easy to Clean and Maintain

The design of Omega Splash Fill allows for quick and simple cleaning, reducing downtime and ensuring long-term operational efficiency.

Construction And Materials

Omega Splash Fill Bars are extruded from durable PVC and designed to prevent sagging between support points. The bars are supported by injection-molded polypropylene grids, ensuring precise vertical and horizontal alignment while minimizing wear and tear.

For installations using stainless steel or vinyl-coated wire grids, injection-molded polypropylene benches provide additional support and stability. However, when using the Gridloc™ Polypropylene System, these benches are not required, simplifying the installation process.

Configuration For Optimal Performance

Fill bar spacing is customizable to meet the specific thermal performance requirements of each cooling tower. The arched fill bars are designed with regularly spaced perforations to maximize airflow and heat exchange efficiency.

Benefits Of Omega Splash Fill

- Improves thermal efficiency with minimal material use.

- Exceeds CTI Standard 136 for strength, flammability resistance, and impact durability.

- Features an innovative arch design that prevents sagging and extends product lifespan.

- Offers flexible installation options to ensure compatibility with any cooling tower design.

- Enables easy cleaning and maintenance, minimizing operational downtime.

The Omega Bench System is engineered for secure and hassle-free installation. For stainless steel or vinyl-coated wire grids, the benches enhance stability and durability. When using the Gridloc™ Polypropylene Grid System, additional benches are not required, further streamlining the installation process.

In conclusion, Omega Splash Fill is the ideal choice for businesses seeking an efficient, durable, and cost-effective solution for crossflow cooling towers. Its thoughtful design ensures long-term reliability and compatibility with a wide range of industrial and commercial cooling applications.