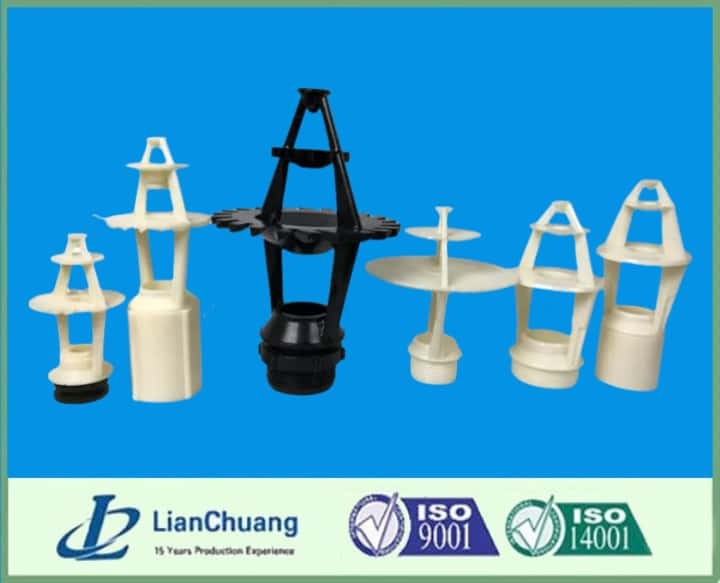

Product Description

The Three Splash Spray Nozzle for cooling towers is designed to provide efficient water distribution with low water pressure. Available in specifications DN43, DN48, and DN60, it features a unique three-splash nozzle system that ensures even water distribution. The nozzle is made from high-strength ABS plastic, offering long service life and resistance to clogging.

Key Features:

1. Flexible Water Flow Control: The nozzle is available in 13mm, 17mm, 19mm, and 26mm sizes, offering a wide range of adjustment for water flow rates and basin water levels, ensuring adaptability for different cooling tower requirements.

2. Multiple Length Options: The nozzle comes in three lengths:

- 2.625 inches: For use in wood, steel, and fiberglass cooling towers where the basin support structure does not obstruct water release.

- 4.875 inches: For larger industrial wood and concrete cooling towers and applications where clogging might be a concern.

- 6.875 inches: For cooling towers where the water release needs to clear obstructions within the tower structure.

3. Efficient Water Distribution: The nozzle ensures even water flow with a working pressure of only 0.6mH2O, making it ideal for systems that require low pressure but efficient operation. It is designed to be highly resistant to clogging and can handle large water pressures.

4. Durable Construction: Made from ABS plastic through injection molding, it provides high strength and longevity, with a typical service life of up to 20 years under normal use.

5. Locking Anti-Loosening Device: The nozzle features a specially designed locking mechanism to ensure a secure connection with the water pipe, preventing disconnection and ensuring long-term safe operation of the water distribution system.

Design Details:

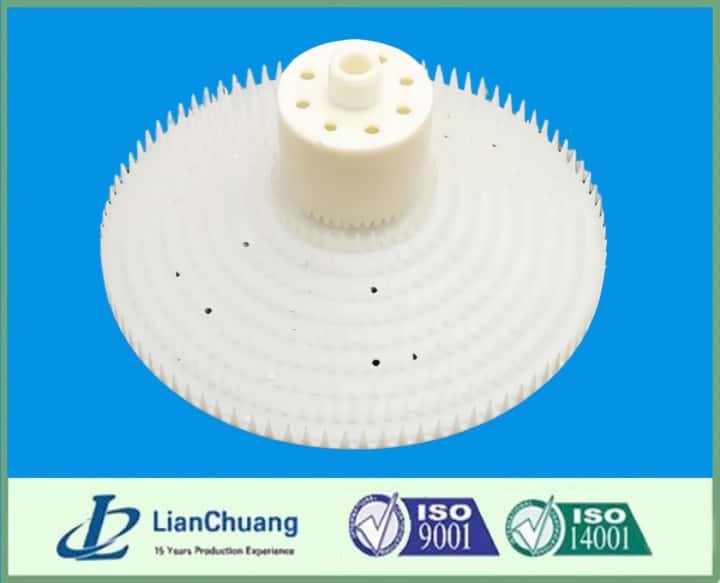

The Three Splash Spray Nozzle incorporates a bottle-shaped interface with a tapered nozzle, arranged in coaxial spacing. The design includes:

- A large splash plate,

- A small splash pan,

- A tapered water head,

- A connecting rod with at least two vertically arranged circumferential sets fixed on a socket-type bottle-shaped interface,

- A splitter plate that divides the nozzle into a cone-shaped nozzle with smaller inner diameters for efficient water release.

Characteristics:

Low Water Pressure: Operates efficiently under low water pressure conditions.

Non-Clogging Design: Designed to prevent blockages, ensuring uninterrupted operation.

High Efficiency: Offers consistent and efficient water distribution across the fill area.

Maintenance-Free: Requires minimal maintenance over its long service life.

For maximum performance, the nozzle should be installed at the correct distance above the top of the cooling tower fill to optimize water distribution.