Product Description

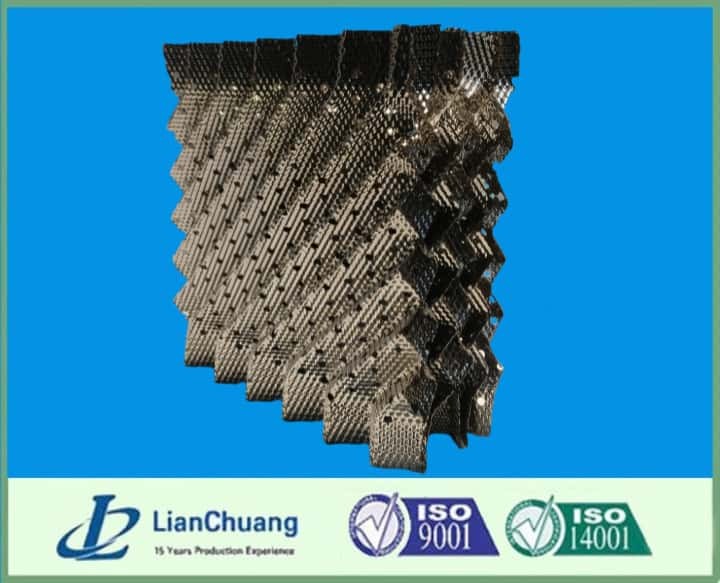

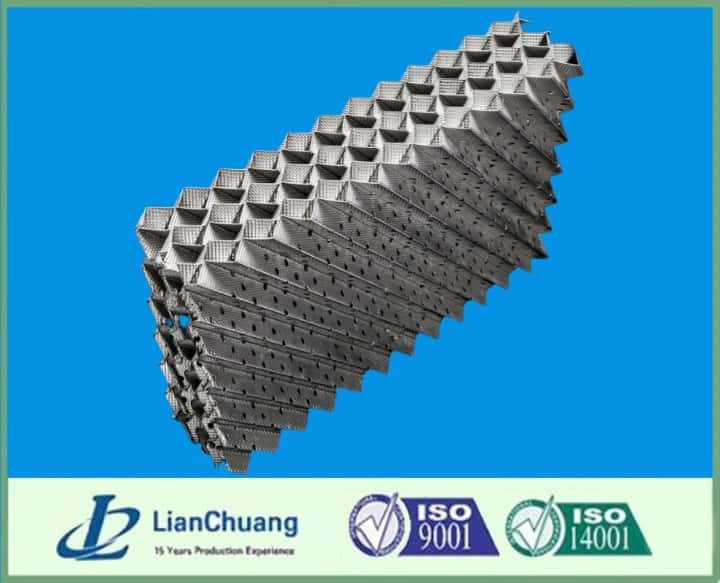

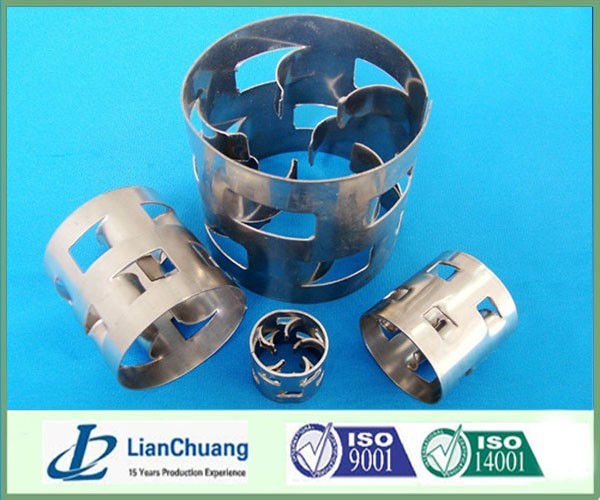

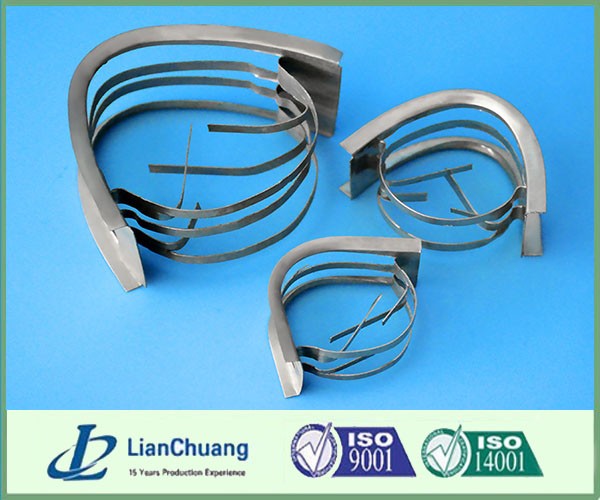

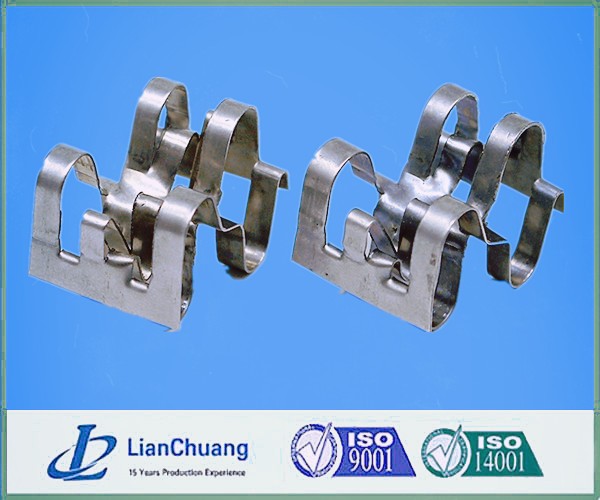

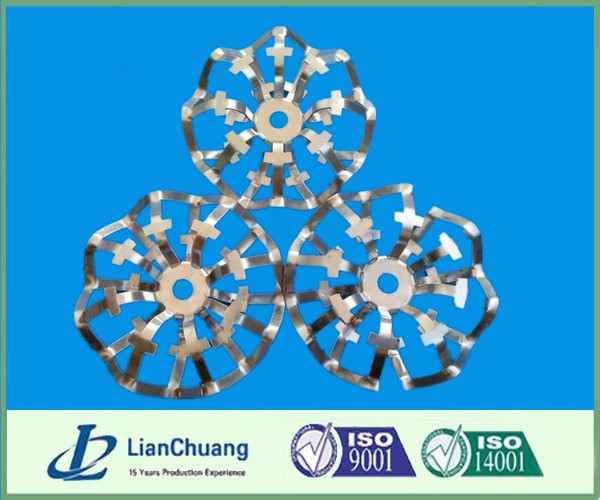

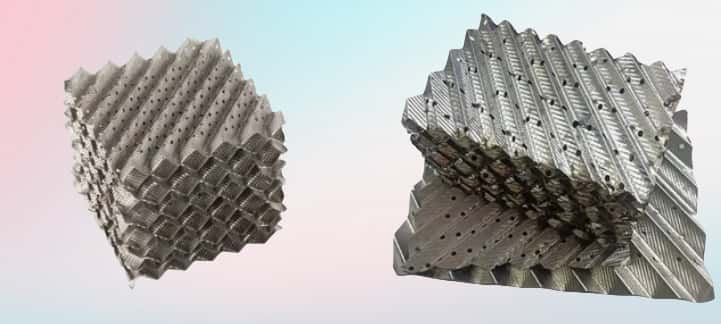

Expanded metal prick corrugated packing is produced by perforating fine holes into metal sheets, which are then shaped into corrugated forms and rolled into coils. This structure improves the wettability of the packing while retaining the superior separation efficiency commonly found in wire mesh corrugated packing.

During operation, liquid flows downward as a film over the packing, while gas ascends through the voids within the structure. Some manufacturers offer perforated plates that facilitate the exchange of phases through the holes in the sheets. However, because each layer of structured packing is not fully connected to the layer beneath it, we have redesigned the filler’s structure by changing the straight channels of the two sections into curved ones. This modification, known as the 252 and 452 Plus types, ensures smoother flow of both phases.

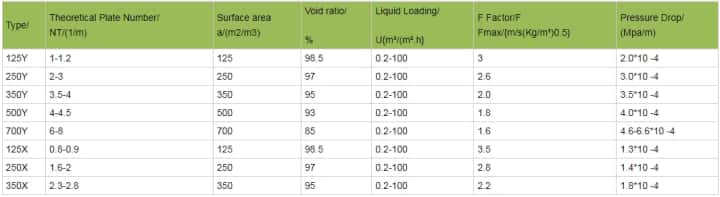

Specifications

Applications

Expanded metal prick corrugated packing is perfect for industries that require high-efficiency separation. Key applications include fine chemicals, solvent recovery, and chemical product refining, among others.