Product Description

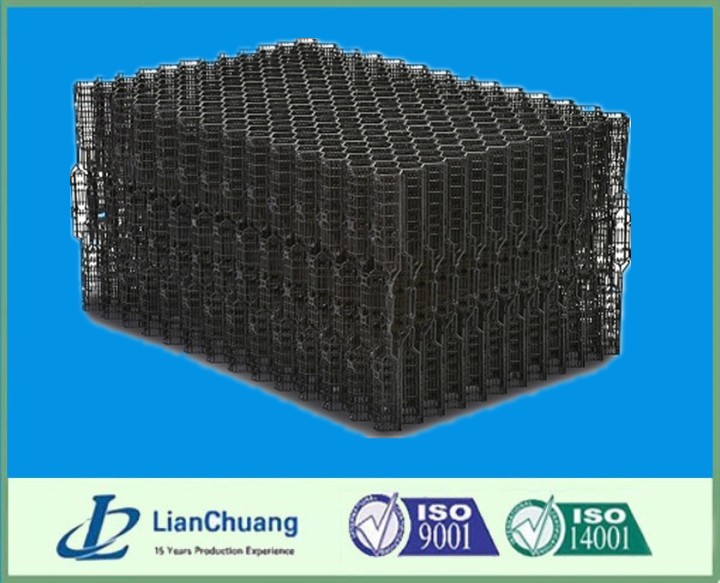

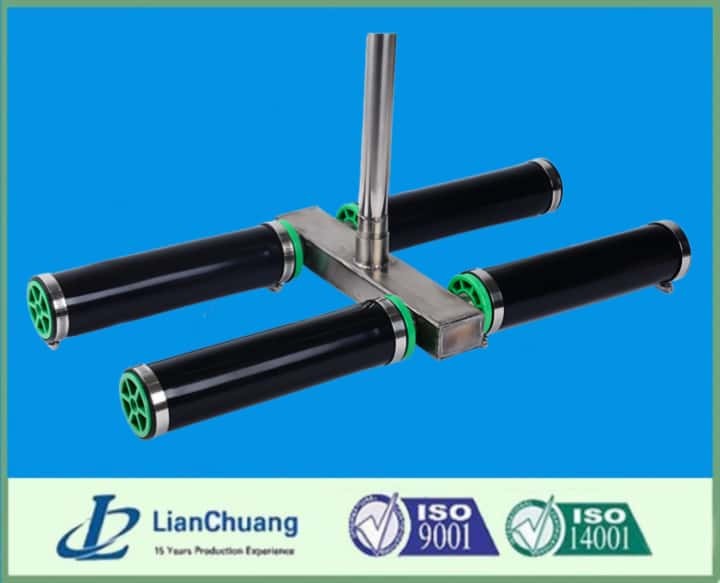

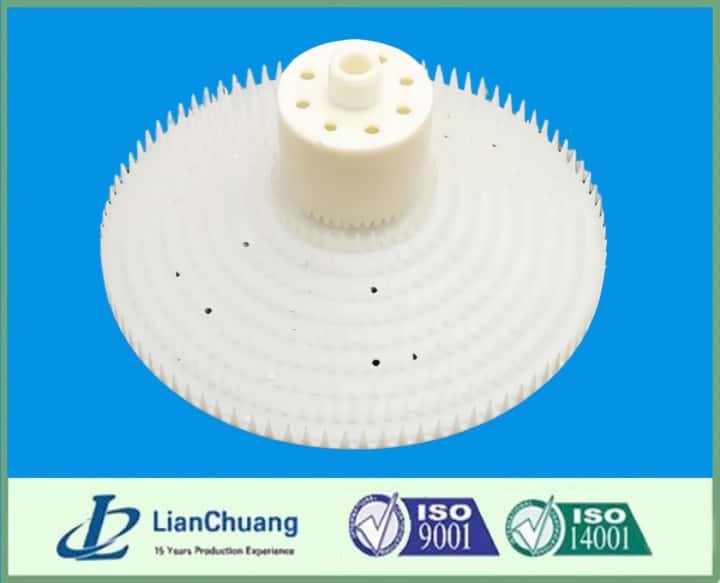

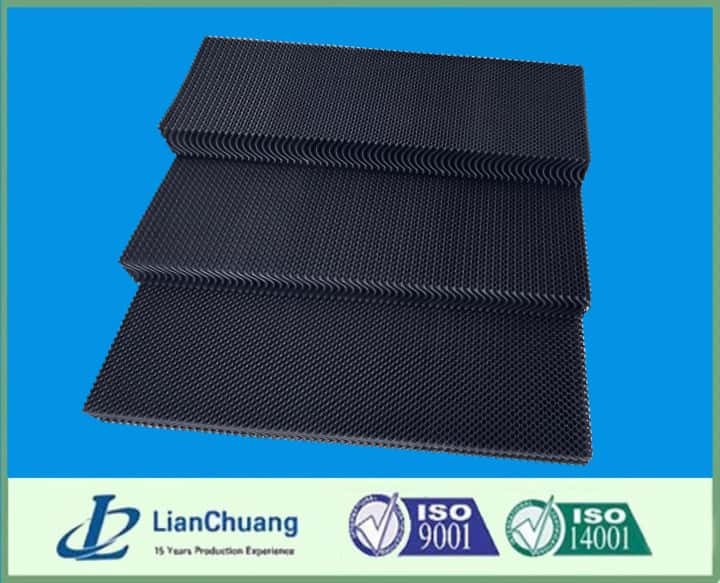

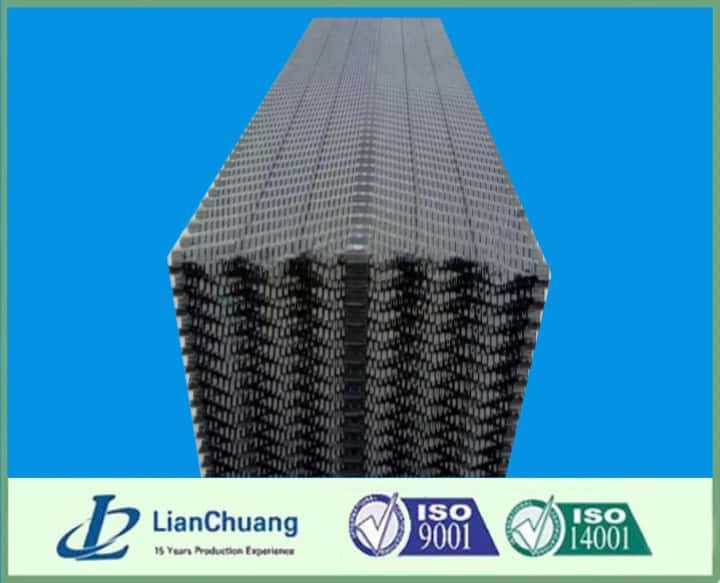

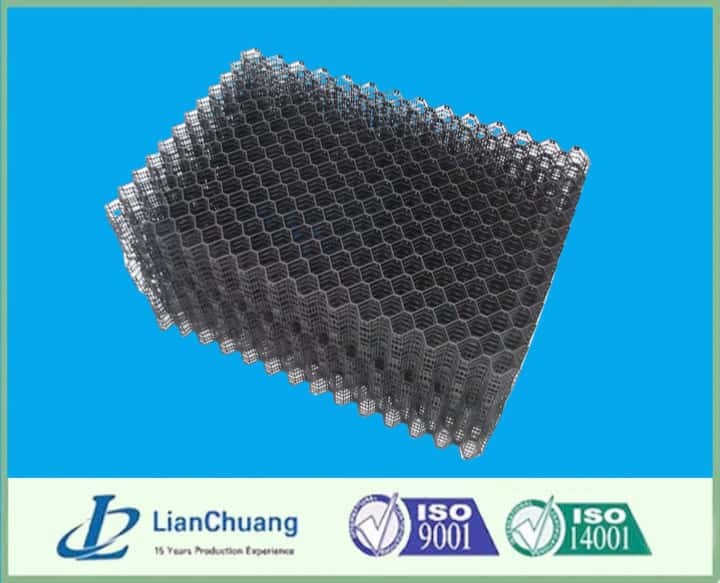

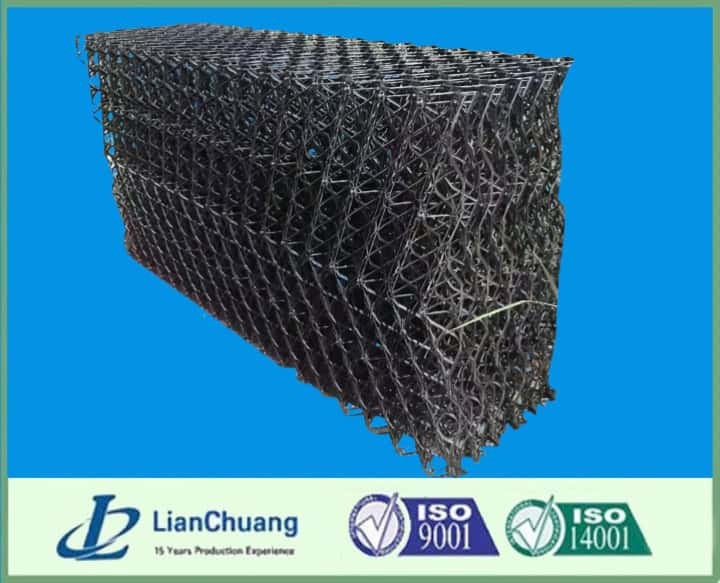

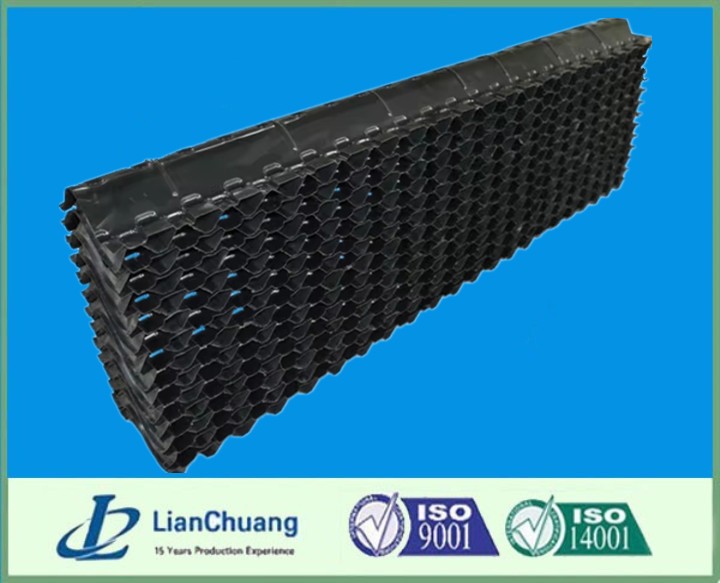

White Black PP PVC Trickle Fill, Grid Fill Trickle Grid Net Fillers are essential components in cooling towers, designed to enhance water distribution and improve heat transfer efficiency. By allowing water droplets to flow slowly over the fill surfaces, trickle fills increase the contact time between water and air, thereby optimizing the cooling process. These fills are specifically engineered to promote efficient thermal performance and maintain the reliability of the cooling tower system.

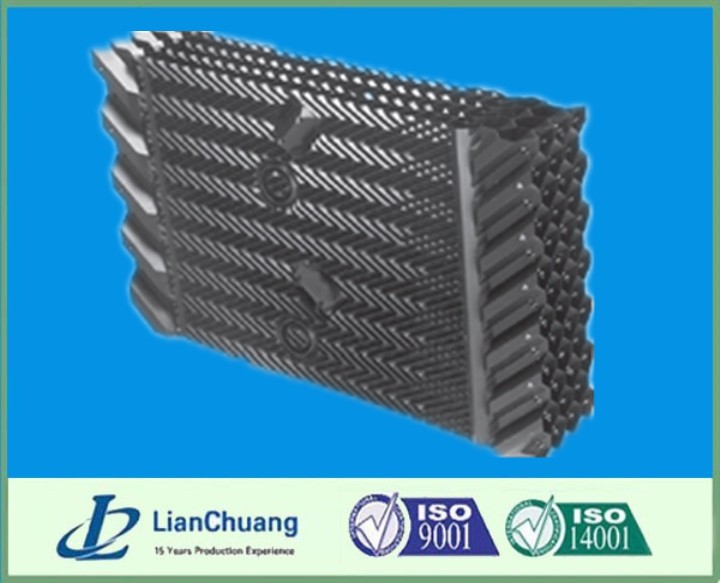

Trickle fills represent a new type of cooling tower fill that combines the features of splash fills and film fills. Their grid structure effectively improves water distribution and disperses the hot water sprayed by the nozzles, thereby enhancing heat transfer performance. PP PVC Trickle Fills utilize mechanically joint connections, eliminating the need for glue, which lowers material costs while achieving safe and eco-friendly results. These new trickle fills are widely used in power plants, chemical plants, and steel plants where suspended solids are high and water quality is poor.

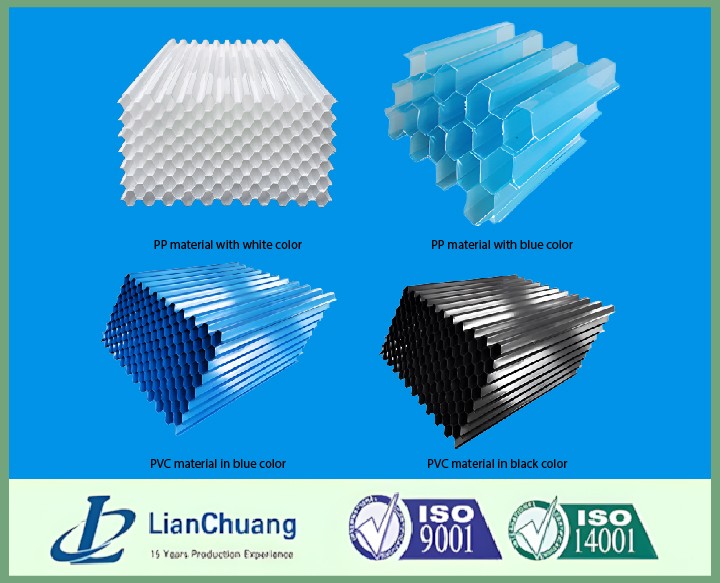

Material

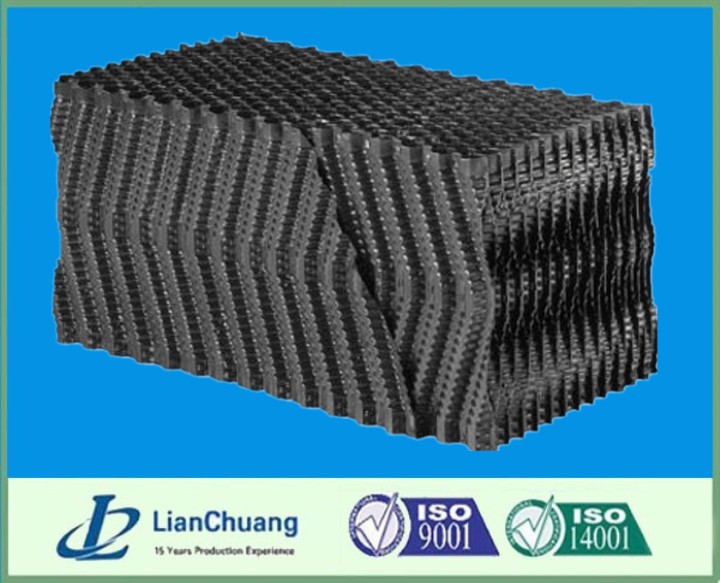

Crafted from high-quality PP material through injection molding, this fill can withstand high temperatures of up to 95°C (for short periods) and offers superior corrosion resistance, ensuring a longer service life compared to PVC film fill.

Structure

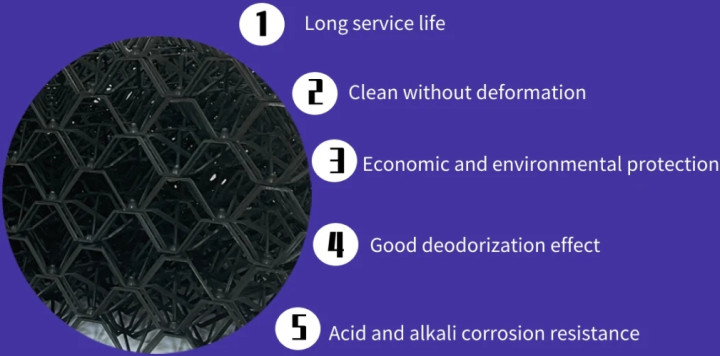

Featuring a grid-type structure, this fill is designed to be clog-resistant and easy to clean. It combines the advantages of trickle fill and film fill, enhancing water distribution by further dispersing the spray water, thereby achieving higher heat transfer efficiency.

Benefits

1.Enhanced Heat Transfer Efficiency: The design of trickle fills maximizes the contact area between water and air, significantly improving heat transfer efficiency. This results in more effective cooling and better overall performance of the cooling tower.

2.Reduced Scaling and Clogging: Compared to traditional fills, trickle fills are designed to minimize scaling and clogging. Their structure ensures that water flows smoothly, reducing the likelihood of blockages and maintaining consistent performance.

3.Improved Cooling Performance: By extending the water flow path, trickle fills enhance the cooling effect. This results in lower water temperatures and increased efficiency of the cooling tower, making it a cost-effective solution for various applications.

4.Durability and Reliability: Made from high-quality materials, trickle fills offer excellent durability and reliability. They are built to withstand harsh industrial environments and provide long-term performance with minimal maintenance requirements.

Key Features

Optimized Water Distribution: Trickle fills ensure uniform water distribution over the fill surface, maximizing the cooling tower's effectiveness.

Efficient Evaporative Cooling: By promoting thorough mixing of water and air, trickle fills enhance evaporative cooling, leading to lower outlet water temperatures.

Low Maintenance: The design of trickle fills reduces the risk of clogging and scaling, resulting in lower maintenance requirements and prolonged service life.

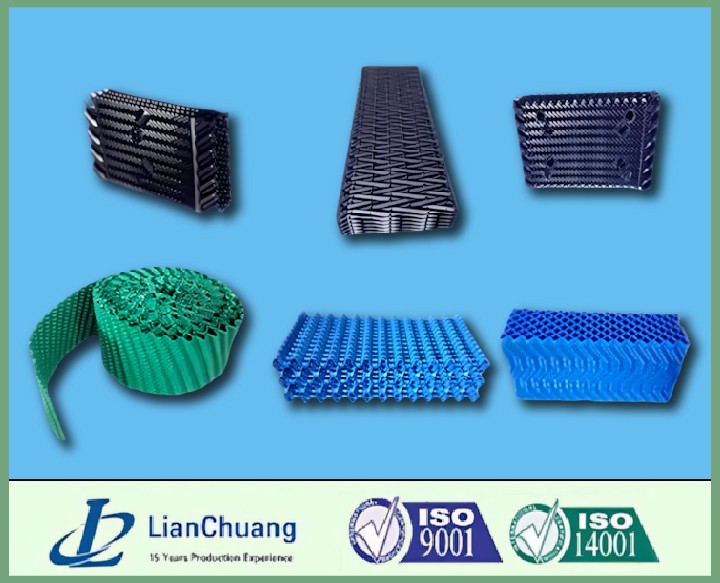

Versatile Material Options: Trickle fills are available in various materials, including those that meet the Cooling Technology Institute (CTI) Standard 136, ensuring compatibility with different cooling tower systems and water qualities.

Application

Power plants

Salt plants

Aluminum factories

Phosphate fertilizer plants

Petrochemical plants

Iron and steel plants

Conclusion

Trickle fills are a vital component in modern cooling tower design, offering significant improvements in heat transfer efficiency, cooling performance, and reliability. Their innovative design minimizes common issues such as scaling and clogging, ensuring optimal operation and longevity. By integrating trickle fills into cooling towers, industries can achieve better cooling efficiency, reduced operational costs, and enhanced system performance.

Material Manufactured using high-quality PP material through injection molding, trickle fills can withstand high temperatures up to approximately 95℃ (for short periods) and offer high corrosion resistance, resulting in a longer service life compared to PVC film fills.

If you need custom trickle fill, please contact our factory to arrange production. With 15 years of manufacturing experience, we are dedicated to providing high-quality products and services. our professional team can meet your needs. Contact us today to experience exceptional custom services and expert solutions.