Product Description

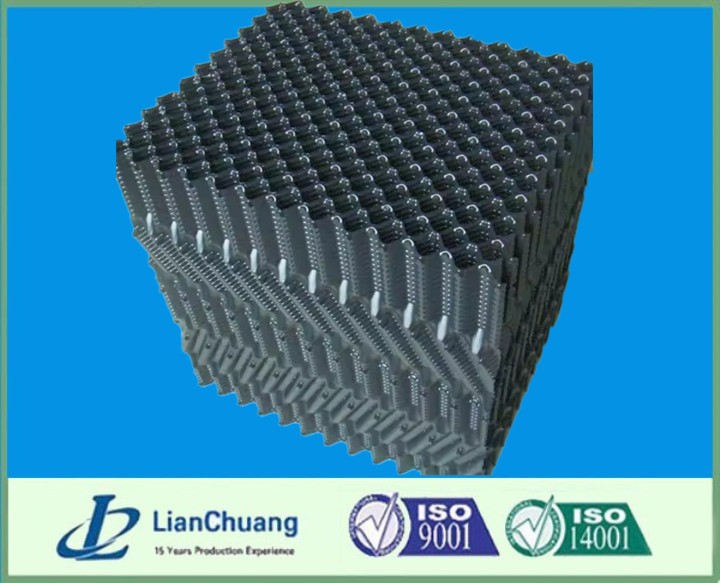

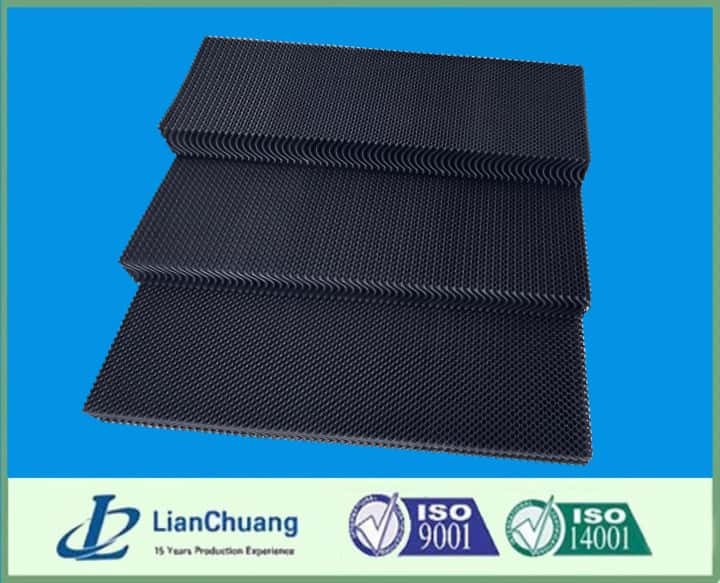

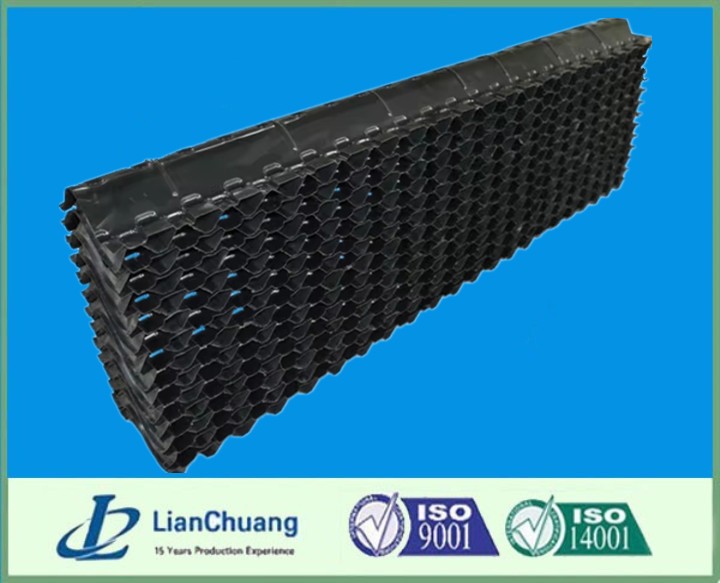

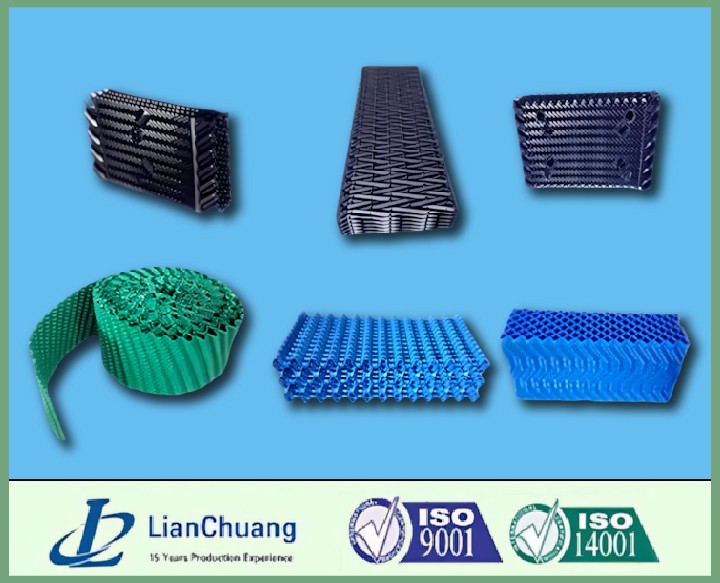

Cooling tower Vertical-Fluted sheet fills or media come in various forms and micro-structures, each designed with unique characteristics to suit different applications. Film fills are chosen for direct replacement, performance enhancement, and compatibility with water conditions. Each type of fill has performance characteristics that allow for optimal selection based on heat loads, flow rates, water quality, and horsepower combinations.

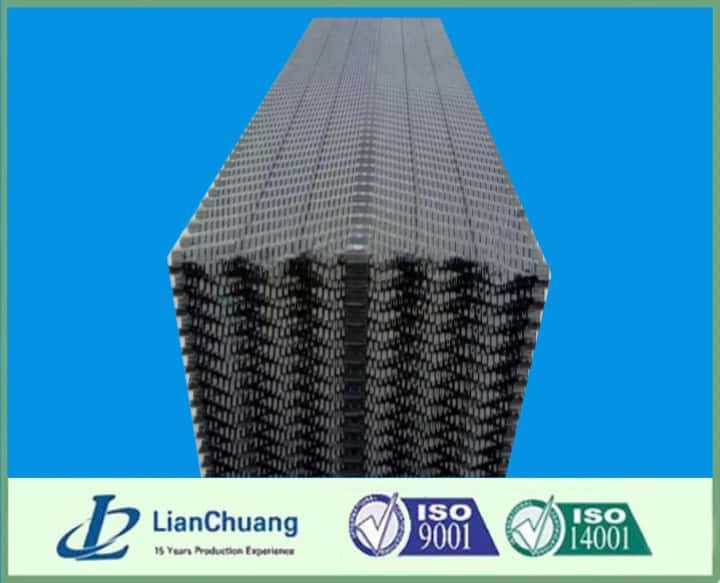

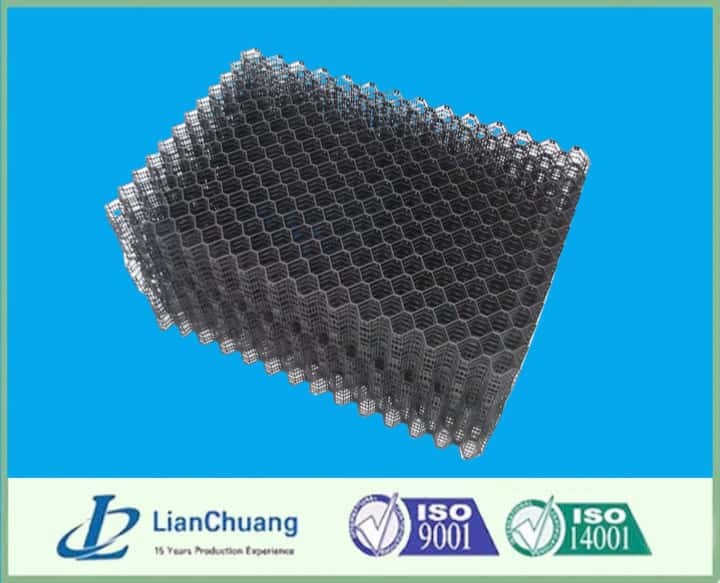

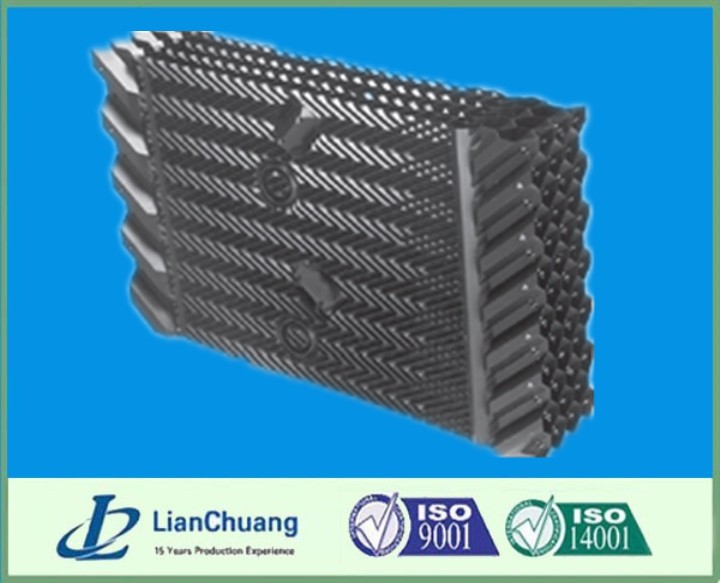

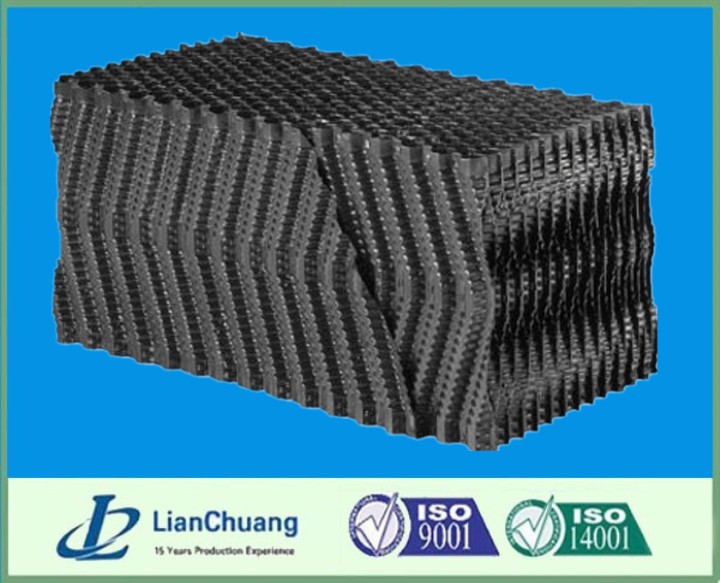

The principle of operation of counter cooling tower fill is to put as much water surface area in contact with as much air as possible, for the longest amount of time possible. Vertical Fluted Fills allow the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow. Cooling tower vertical fills feature vertical flow channels with large openings, which produce high water speeds, creating an anti-fouling environment within the fill. These are ideal for counter-flow cooling towers where water quality is poor.

Vertical-Fluted Fills Features:

Larger flute openings for maximum water speed

Proprietary edge-cutting technology creates square packs that efficiently direct water to both sides

Bonded edges with dedicated bond points for added strength and durability

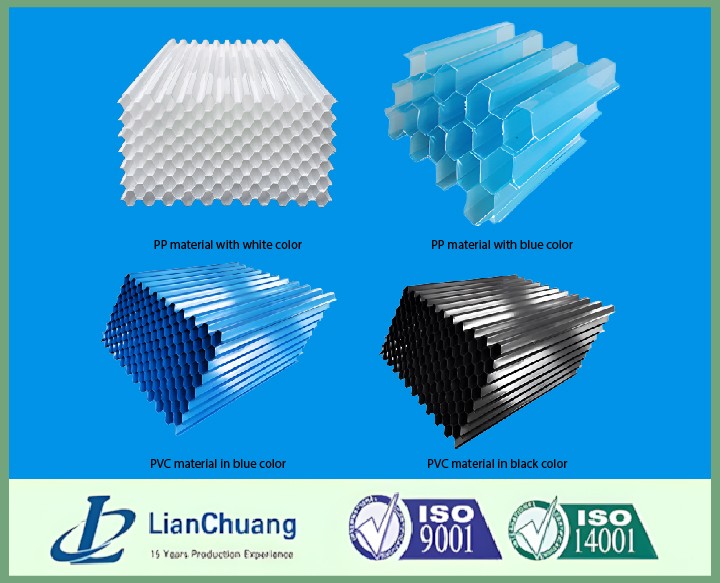

Made of PP or PVC

Resistant to UV, corrosion, organic/inorganic acids, alkali, and chemicals typically found in cooling tower water

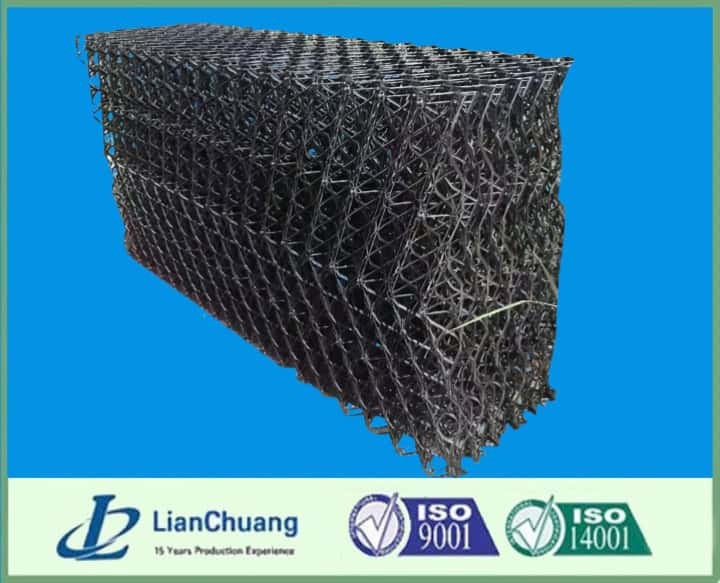

Available in various vertical design structures

Reinforced edges for better strength and reduced cost

Self-supporting structure

High temperature and chemical resistance

Erosion resistance due to multiple welding points

Flame retardant

Excellent mechanical resistance

Good cooling performance

Vertical-Fluted Fill Application:

Cooling tower vertical flow fills are used in applications where circulating water contains high levels of suspended solids, such as water from high cycles of concentration, rivers, or seawater.