Product Description

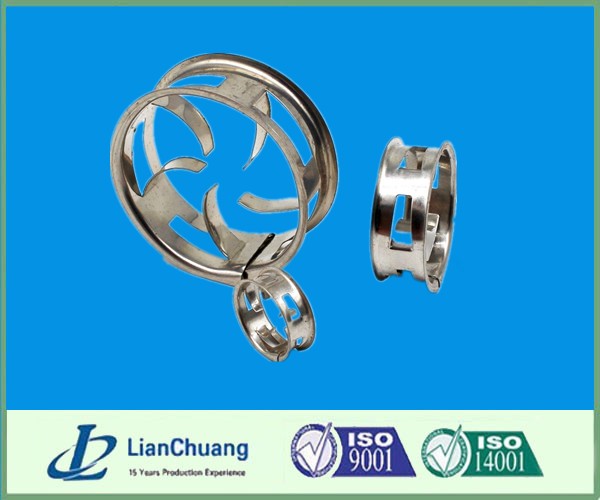

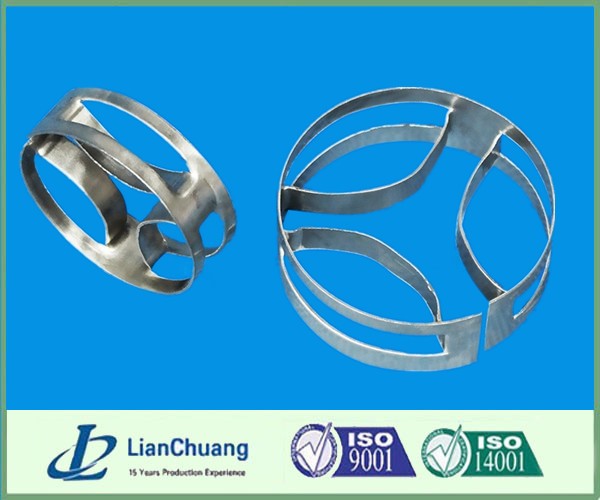

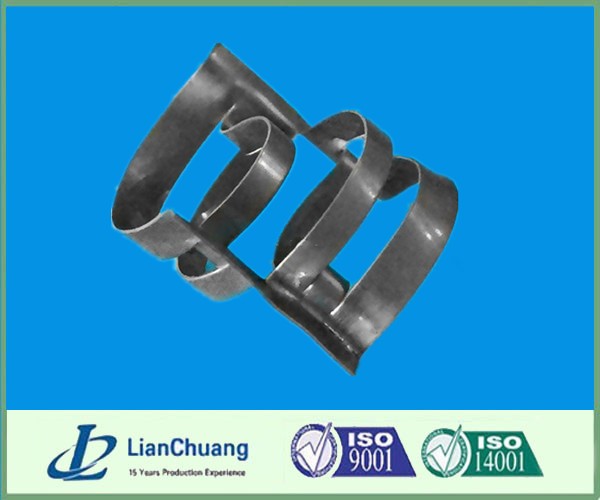

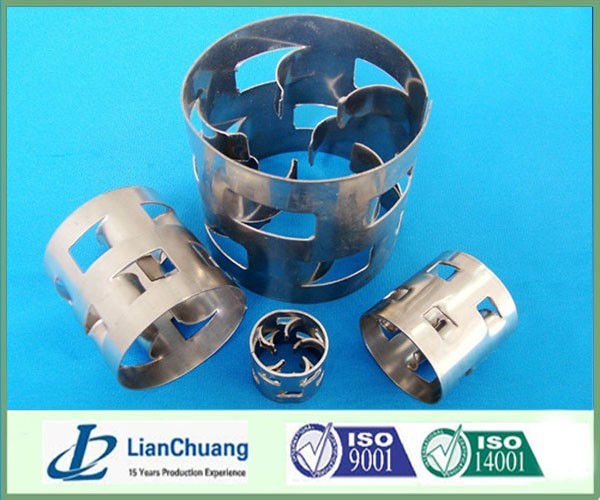

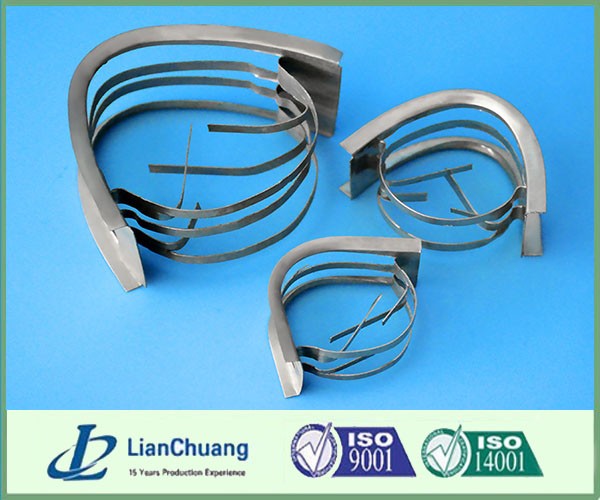

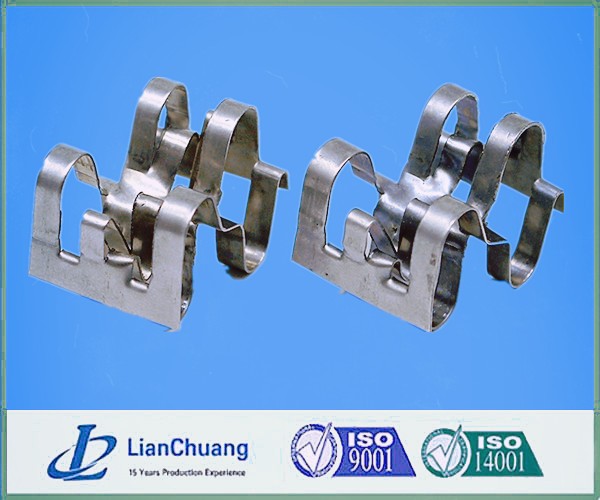

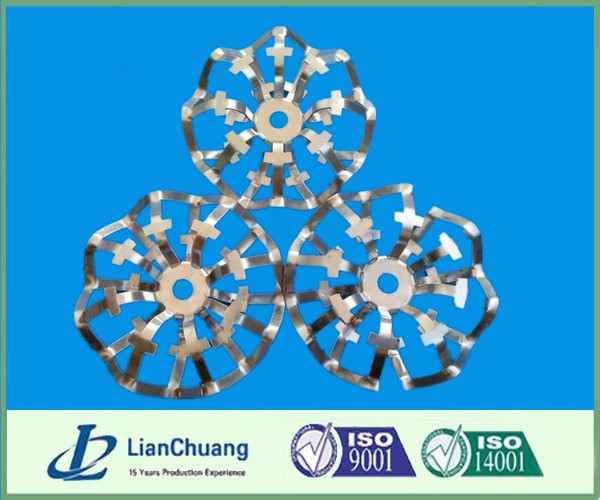

Metal cascade ring ( CMR ) is a new hole-type packing developed on the basis of and raschig ring, it has low aspect ratio. (1/3 or 1/2 of High/Diameter) And metal cascade mini ring has higher operational efficiency occurs, because metal cascade ring’s preferential orientation which ensures that in most of the ring surface are positioned vertically rather than horizontally, and this is also advantageous for mass transfer (its also the main superiority compare to the metal pall ring). So metal cascade mini ring can reduces resistance when the gas goes through the machine bed and increases flow rate. As metal cascade ring’s form, it can reduce the pressure drop significantly and also allows additional vapor, liquid handling and increases plant capability. And any solids entering the packed bed are more easily flushed through the packing matrix. Metal cascade rings ( CMR ) are available in a wide range of materials, such as carbon steel, stainless steel: SS304, 304L, SS400, 410,316, 316L etc.

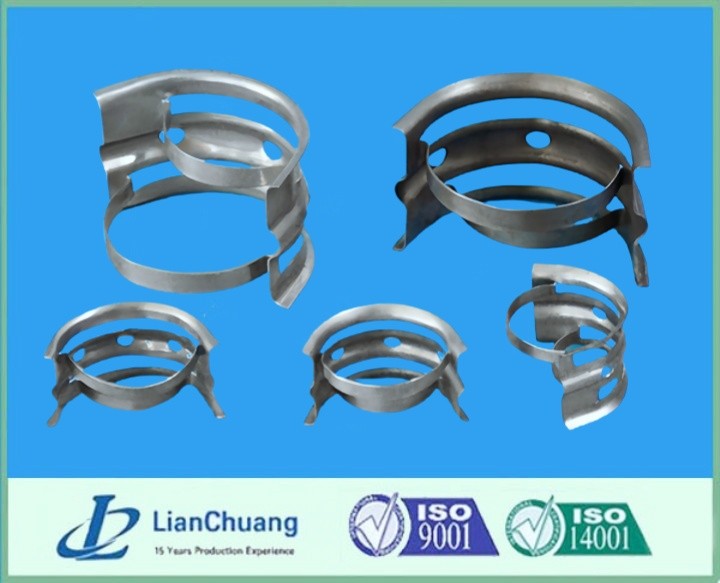

Size of metal cascade ring:

25mm, 38mm,50mm,76mm

Advantage of metal cascade ring:

reduced pressure drop, increased plant capacity, improved resistance to fouling, higher operational efficiency

Applications of metal cascade ring:

Metal cascade ring can be applied in desulphurization and decarburization system in compound ammonia plant and decompressed plant in crude oil separated plant. Metal cascade mini ring ( CMR ) can be also used for all kind of separation process such as separation of methanol, organic acid.

Specifications of metal cascade rings:

Dimension | Thickness | Number | Bulk density | Surface area | Free volume |

(mm) | (mm) | per m3 | (kg/m3) | (m2/m3) | (%) |

25×12.5 | 0.5 | 97160 | 383.5 | 220 | 95.1 |

38×19 | 0.8 | 30040 | 325 | 154.3 | 95.9 |

50×25 | 0.8 | 12340 | 308 | 109.2 | 96.1 |

76×38 | 1 | 3540 | 306 | 73.5 | 961 |

Note: Metal cascade min ring material: Stainless steel, carbon steel, carbon steel seeping aluminum such as 304, 304L, 410,316, 316L. and so on.