Product Description

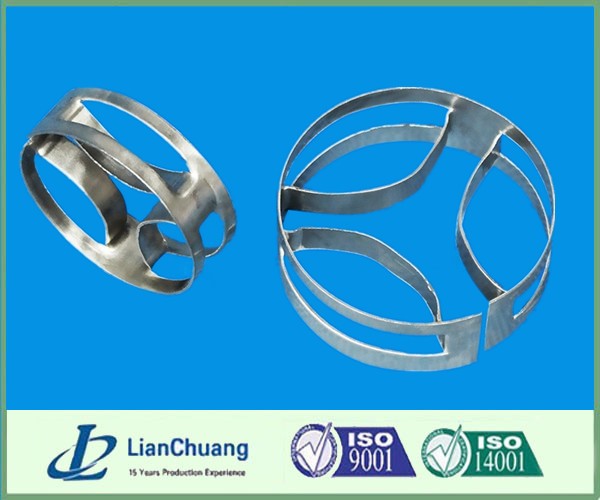

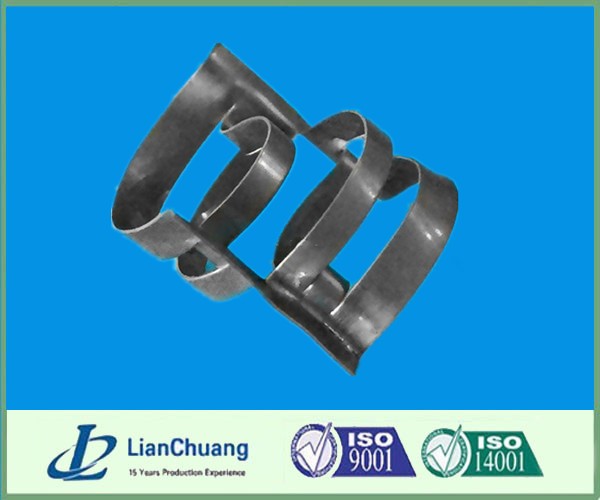

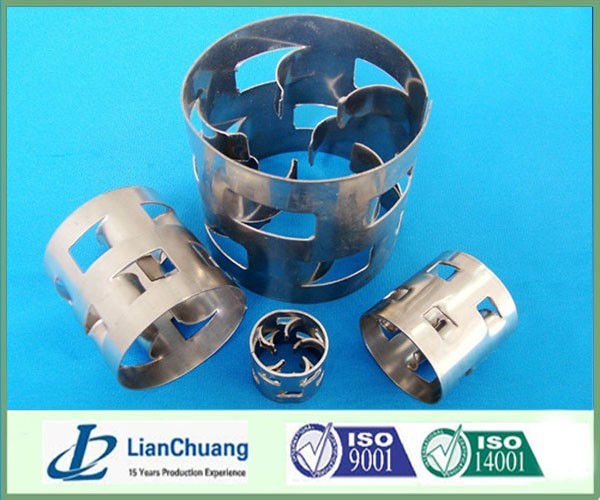

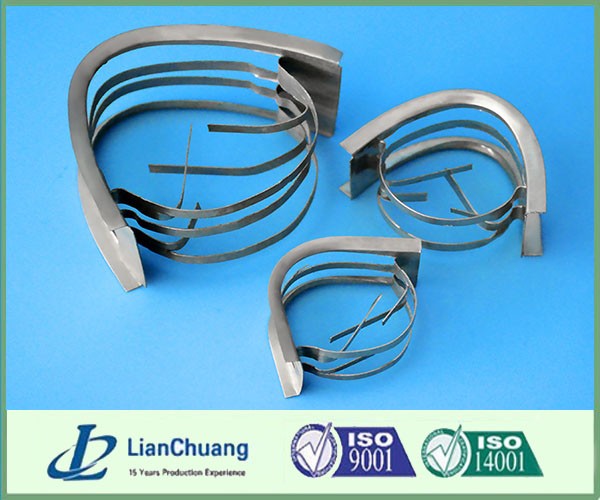

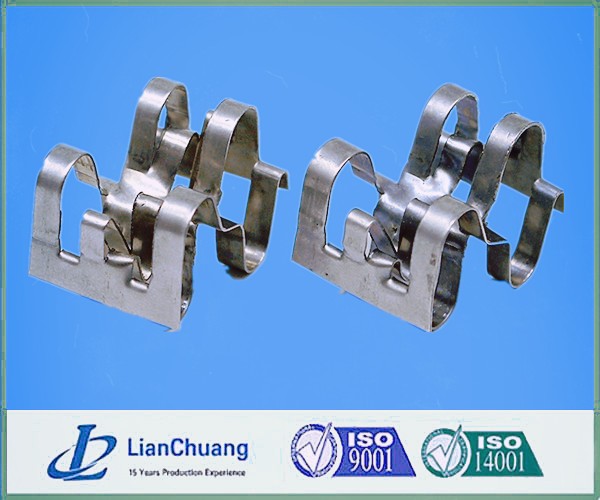

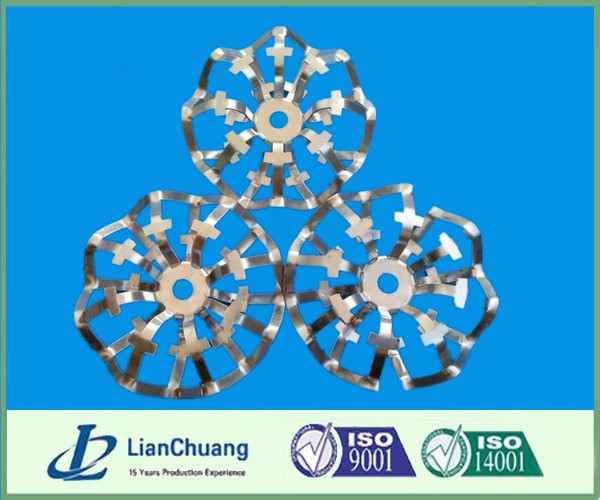

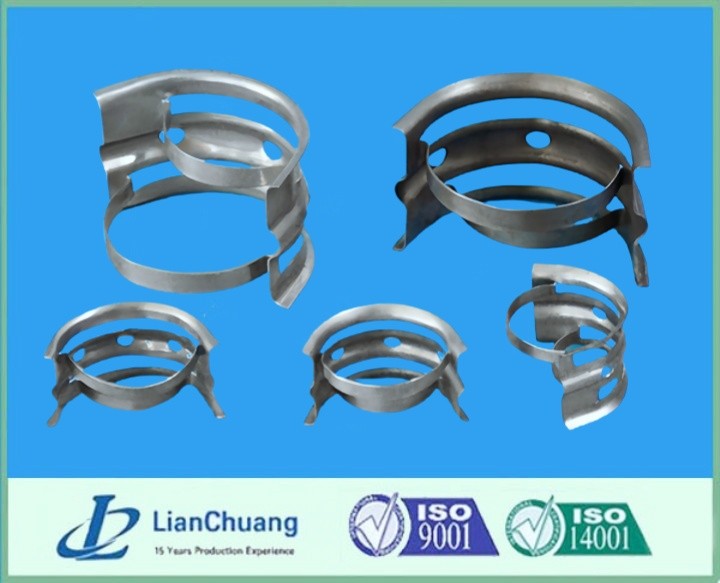

Metal super mini ring , metal flat ring is always thought as the shorter cascade mini ring, because Super Mini Ring has the similar shape of cascade mini ring without top turn-ups. It also can be called as Metal flat ring. Metal Super Mini Ring’s flat ring bent arc reinforced angle characteristics make less fluid resistance, and enlarge liquid & gas contact on easily wet surfaces. Metal Super Mini Ring (metal flat ring) has which has improved the packing of the hydrodynamics and mass transfer. Its performance is better than pall ring, as the axial mixing is small, the mass transfer effects may be increased by 20% or more.

This kind of metal random packing can applied to gas-liquid mass transfer process.The Metal Flat Ring (SMR), also known as the Metal Super Mini Ring, is a random packing specifically designed for the liquid-liquid phase flow. With its unique structure, it effectively enhances the dispersion, aggregation, and re-dispersion processes of droplets, optimizing the mass transfer efficiency between liquids. The symmetric, inward-curved fins improve the homogeneity of fluid flow, reduce the agglomeration of droplet clusters, and significantly increase the efficiency of liquid-liquid mass transfer.

Features

- Optimized Liquid-Liquid Mass Transfer: The unique design of the inward-curved fins enhances the homogeneity of fluid flow, reduces droplet agglomeration, and promotes the dispersion and re-dispersion of droplet clusters, improving liquid-liquid mass transfer efficiency.

- Reduced Axial Back-Mixing: The structure helps minimize axial back-mixing of the liquid phase, which further enhances the efficiency of the mass transfer process.

- High Mechanical Strength: Made from high-strength metal materials, the Metal Flat Ring has excellent mechanical strength and resistance to compression, ensuring stability under high load or pressure environments.

- Efficient Dispersion and Aggregation: The design effectively impacts the liquid's dispersion and aggregation processes, ensuring efficient mass transfer in various applications.

Applications

- Liquid-Liquid Extraction: Metal Flat Ring is particularly suitable for liquid-liquid extraction towers, effectively improving the efficiency of mass transfer between liquids. It is widely used in chemical, petroleum, pharmaceutical, and other industries.

- Water Treatment: In water treatment processes, it enhances the uniformity of fluid flow, optimizes chemical reactions, and reduces sedimentation of impurities for improved processing.

- Gas-Liquid Absorption and Scrubbing Towers: Suitable for gas-liquid interactions and gas scrubbing processes, improving washing and absorption efficiency.

- Distillation and Rectification Columns: In distillation and rectification processes, Metal Flat Ring enhances the uniformity of fluid flow and improves solute separation efficiency, ensuring higher separation precision.

- Scrubber Towers and Coking Towers: Effectively handles complex chemicals and particulates, ensuring excellent gas-liquid contact and reaction, stabilizing tower operation.

Technical Specifications

- Material: High-quality stainless steel, copper, aluminum alloy, or custom materials based on customer requirements.

- Size: Outer Diameter: 10mm-100mm (customizable); Height: 5mm-20mm (customizable).

- Specific Surface Area: 200-500 m²/m³ (varies by specific model).

- Density: 0.20-0.30 g/cm³.

Advantages & Economic Benefits

- Increased Efficiency: The Metal Flat Ring's design optimizes the dispersion and aggregation processes of droplets, significantly improving liquid-liquid mass transfer efficiency and shortening reaction time.

- Reduced Energy Consumption: By improving fluid flow uniformity and operational stability, energy loss due to uneven flow is minimized.

- Increased System Reliability: Made from high-quality metal materials, it ensures long-term stability under high temperatures and pressures, providing reliable performance.

- Reduced Maintenance Costs: Its corrosion resistance and long service life reduce the frequency of replacement and maintenance, lowering operational costs.

Conclusion

The Metal Flat Ring (SMR or Metal Super Mini Ring) offers excellent liquid-liquid mass transfer performance and structural stability, making it an ideal choice for applications in liquid-liquid extraction, distillation, gas-liquid absorption, and many other processes. Its use across various industrial sectors helps businesses improve production efficiency, reduce energy consumption, and realize economic benefits. Whether in water treatment, distillation columns, scrubbers, or complex coking and dust removal processes, the Metal Flat Ring provides strong support for efficient and stable tower operation.

If you have any customization needs or would like to learn more about our products, please feel free to contact us.