Product Description

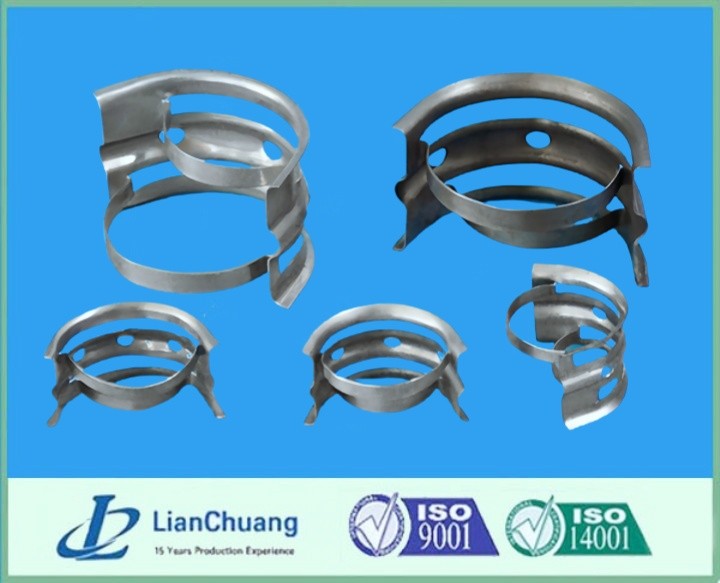

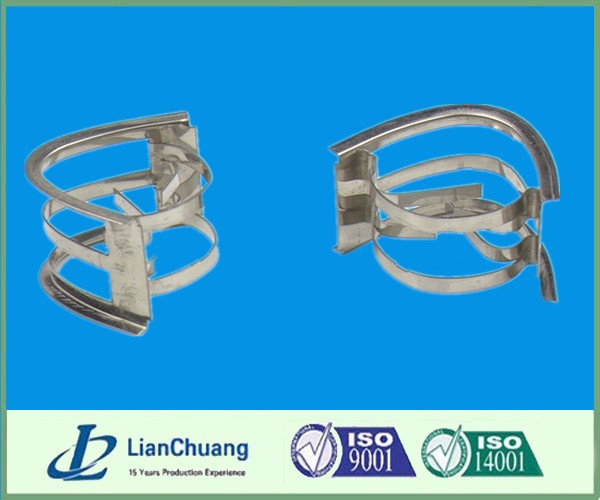

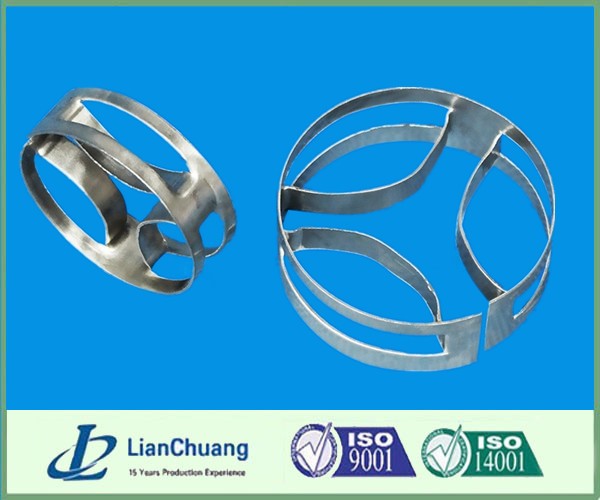

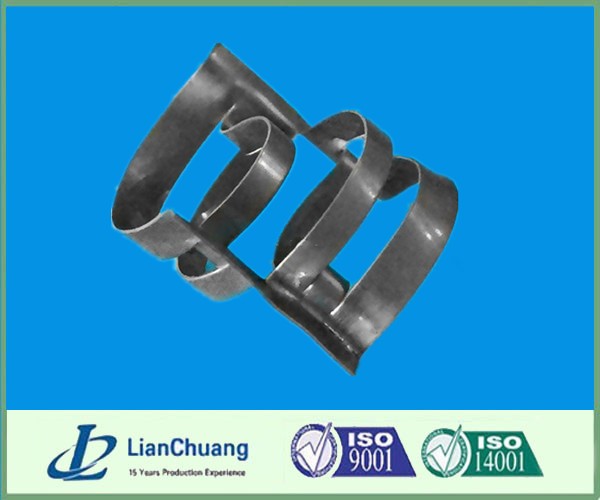

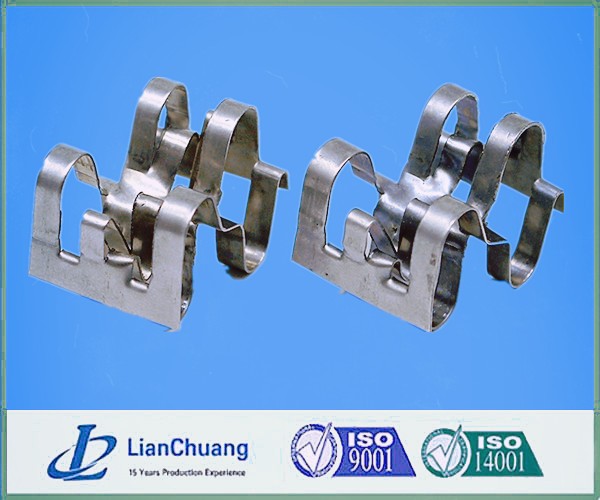

Metal nutter ring, developed by Dale Nutter in 1984, is a high-performance random packing designed to optimize various industrial processes, particularly in the fields of separation and absorption. Known for its superior efficiency and performance, the Nutter Ring has undergone extensive testing by the Fractionation Research Institute (FRI), solidifying its reputation as one of the best random packings available.

Nutter ring, 304,316L mettaliic nutter rings packing is a high performance metal random packing verified by Fractionation Research Institute ( FRI ). nutter ring, 304,316L mettaliic nutter rings’ efficiency enhanced by lateral liquid spreading and surface film renewal. Metal nutter ring not only have superior surface utilization in mass and heat transfer but also make the packed be height shorter .

Design and Features

- High Mechanical Strength

- Low Pressure Drop

- Maximum Piece-to-Piece Contact

- Anti-Corrosion and High Temperature Resistance

- Cost-Effectiveness

Main Benefits

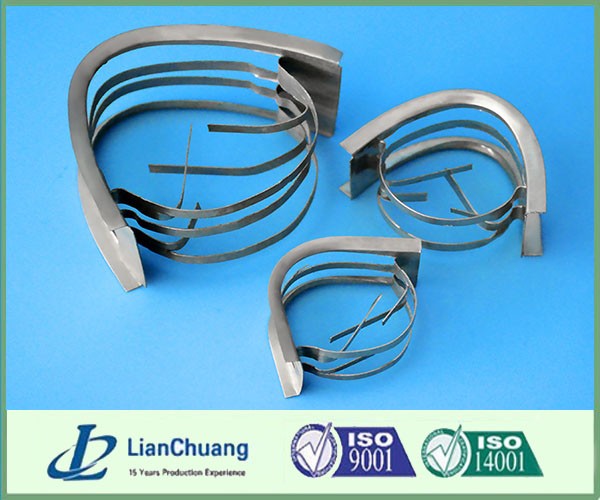

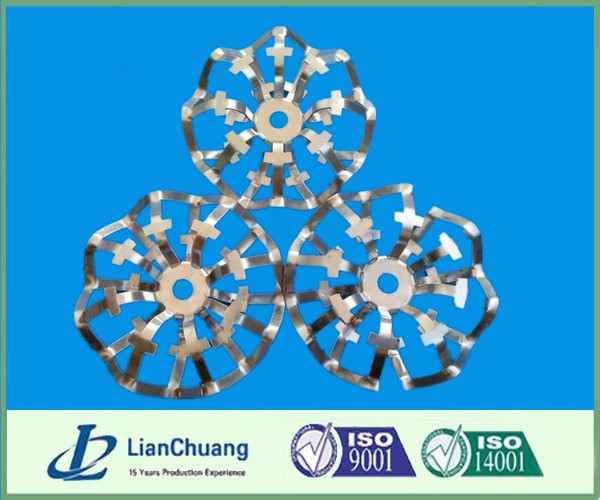

The Metal Nutter Ring offers numerous advantages over other packing types, such as the metal cascade mini ring and metal pall ring:

- Versatile Applications: Effective in a wide range of operational contexts.

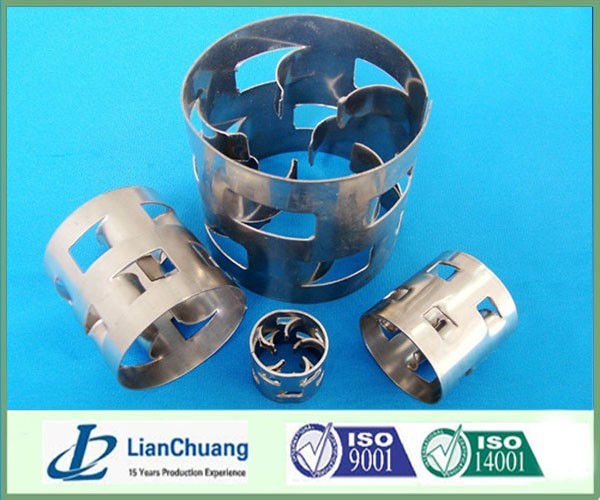

- Multiple Geometries and Materials: Available in various shapes and materials, including carbon steel, aluminum alloy, and stainless steel (SS304, SS304L, SS316, SS316L).

- Ease of Replacement and Storage: Simplifies maintenance and logistics.

- Ideal for Heavy Fouling or Corrosive Environments: Ensures reliable performance in challenging conditions.

Specifications of nutter rings:

Size | Number | Bulk density | Surface area | Free volume | |

(inch) | (mm) | (n/m3) | (kg/m3) | (m2/m3) | (%) |

0.7 | 17.5 | 167400 | 176 | 266 | 97.7 |

1 | 25 | 67100 | 178 | 168 | 97.7 |

1.5 | 38 | 26800 | 181 | 124 | 97.8 |

2 | 50 | 13600 | 173 | 96 | 97.8 |

2.5 | 63 | 8800 | 83 | 83 | 97.9 |

3 | 76 | 4200 | 66 | 66 | 98.1 |

Material: aluminium, SS304, SS304L, SS316, SS316LL, SS321

The specification just for stainless steel metallic nutter rings with standard material thickness. Other thicknesses are available upon request.

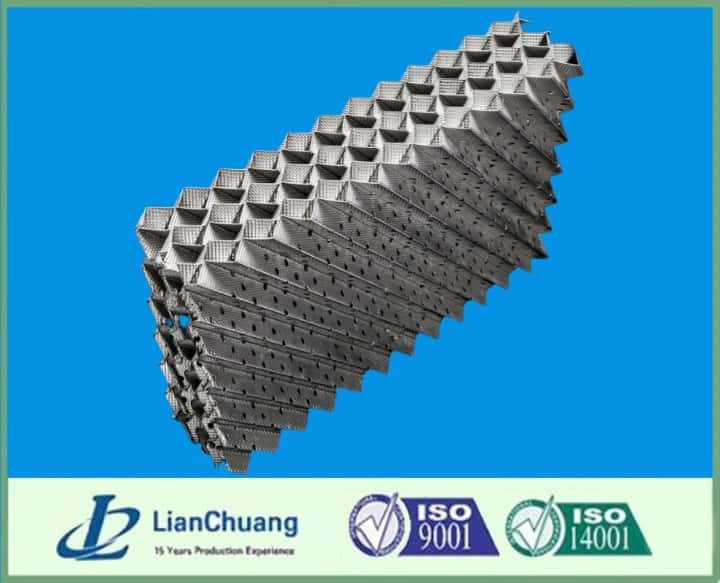

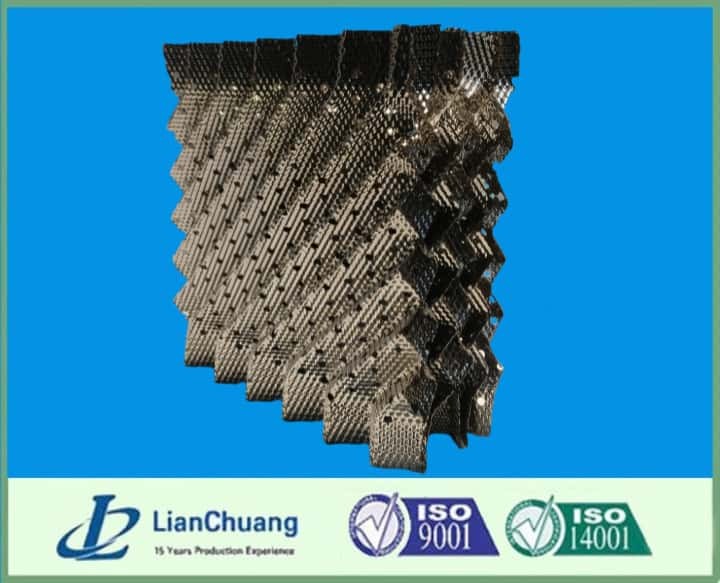

Applications

For fractionation, absorption, and stripping processes.

Applicable to gas, refining, and chemical manufacturing facilities.