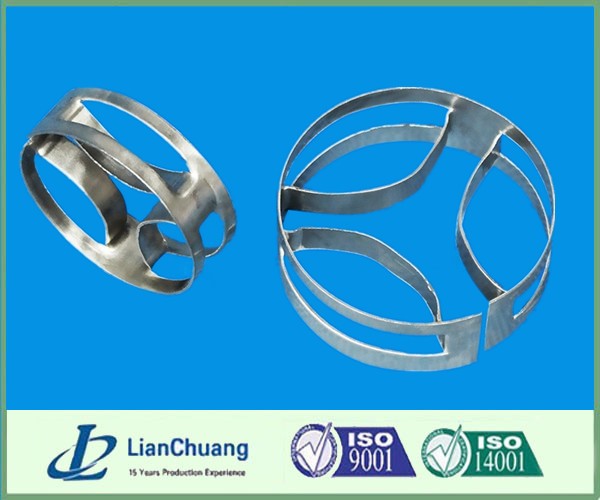

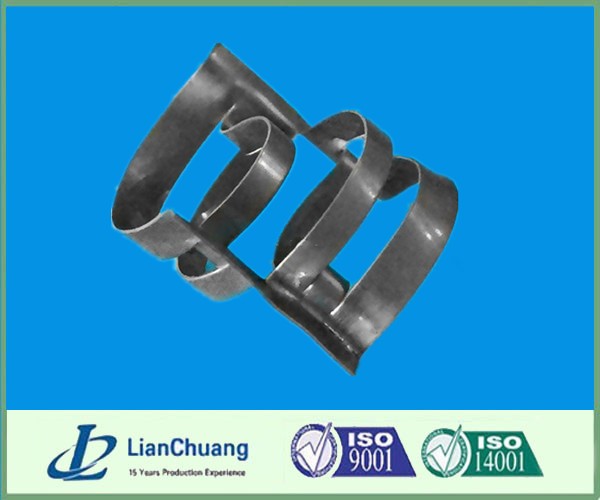

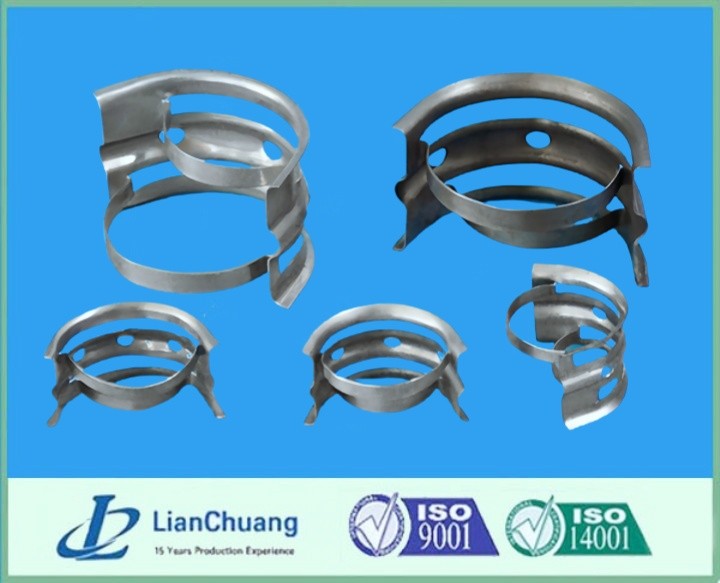

Product Description

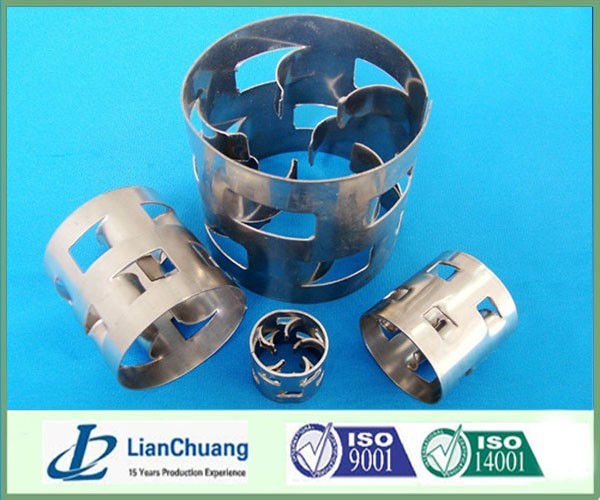

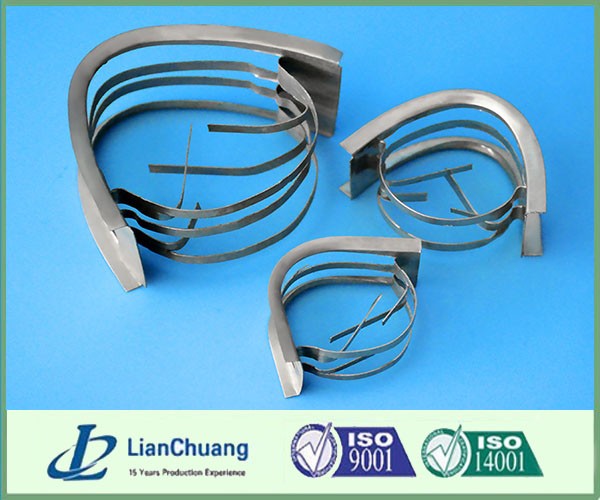

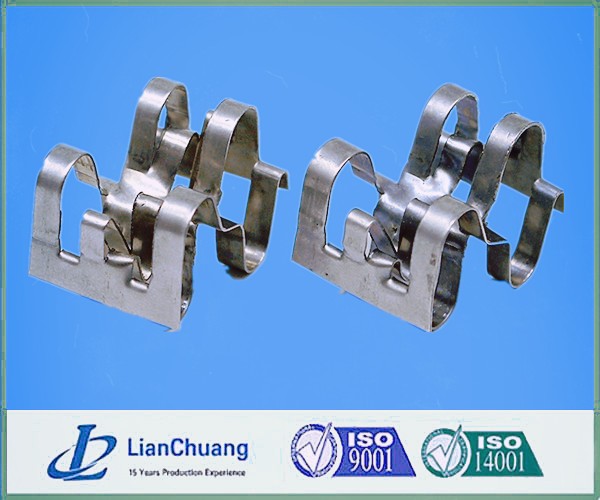

Metal I-RING random packing is a cutting-edge metallic packing media that excels in various industrial applications, especially in shorter packed bed heights. This high-performance, random packing solution combines superior efficiency with a low-pressure drop, making it an ideal choice for both high-pressure and vacuum towers. The saddle-shaped design of the I-RING minimizes pressure drop while maintaining high vapor and liquid load capabilities, ensuring optimal performance across a range of applications.

Key Features and Advantages of Metal I-RING Random Packing:

- Low Pressure Drop: The I-RING offers up to 30% lower pressure drop compared to traditional packing media like Pall Rings, which significantly enhances energy efficiency in systems.

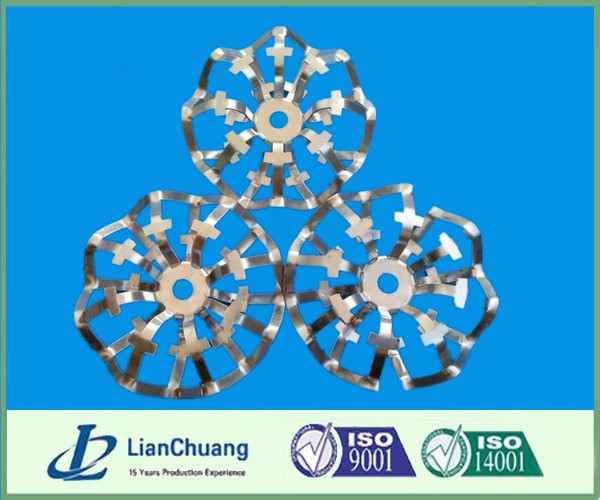

- High Efficiency: It provides a large effective interfacial area, resulting in better mass transfer and improved separation performance.

- Durable and Strong: With its robust mechanical strength, the I-RING is highly resistant to mechanical wear and deformation, ensuring a long service life and reducing maintenance costs.

- Versatile Sizing: Available in various sizes, the I-RING allows for customized solutions that balance efficiency and pressure drop according to specific operational needs.

- Low Liquid Hold-up: Its optimized design reduces liquid retention, improving overall system performance and efficiency.

- Maximum Randomness, Minimum Alignment: The unique physical shape of the I-RING facilitates maximum randomness in the packing, reducing the risk of alignment and ensuring stable, continuous operation.

Applications of Metal I-RING Random Packing:

- Distillation Columns: Ideal for both distillation and absorption columns, particularly where lower packed bed heights are required.

- Ammonia and CO2 Absorption: Effectively used in gas absorption processes like CO2 and ammonia absorption, providing high mass transfer and low pressure drop.

- Air Pollution Control: A key solution in the treatment of industrial emissions, improving air quality and compliance with environmental standards.

- High-Pressure and Vacuum Towers: Suited for use in both high-pressure and vacuum towers, the I-RING excels in processes requiring controlled conditions and high separation efficiency.

Additional Benefits:

- Advanced Material Options: Available in a range of grades of steel, copper, and special alloys, providing versatility for different temperature and chemical environments.

- No Minimum Order Quantity: Flexible order options to meet both small and large project requirements.

- Certified Quality: Full quality assurance and material certification are available for peace of mind regarding product performance and consistency.

Why Choose Metal I-RING Random Packing?

The metal I-RING packing enhanced efficiency and reduced operational costs. By lowering pressure drop and improving separation efficiency, this innovative packing solution is a smart investment for industries like chemical processing, petrochemical refining, and air pollution control. With its advanced design, durability, and cost-effectiveness, the I-RING is a preferred choice for businesses seeking to optimize performance and reduce operational costs

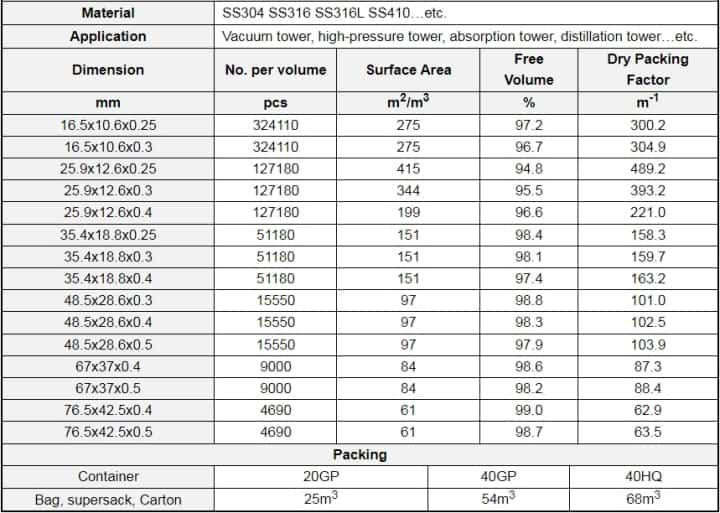

Specifications:

The metal I-RING random packing is a reliable, high-performance solution for industries requiring efficient mass transfer, low pressure drop, and long-term durability. Its versatility across various applications and materials makes it a standout choice for both new and retrofitted installations in distillation, absorption, and pollution control systems. Choose I-RING packing for better efficiency, reduced energy consumption, and higher operational savings.