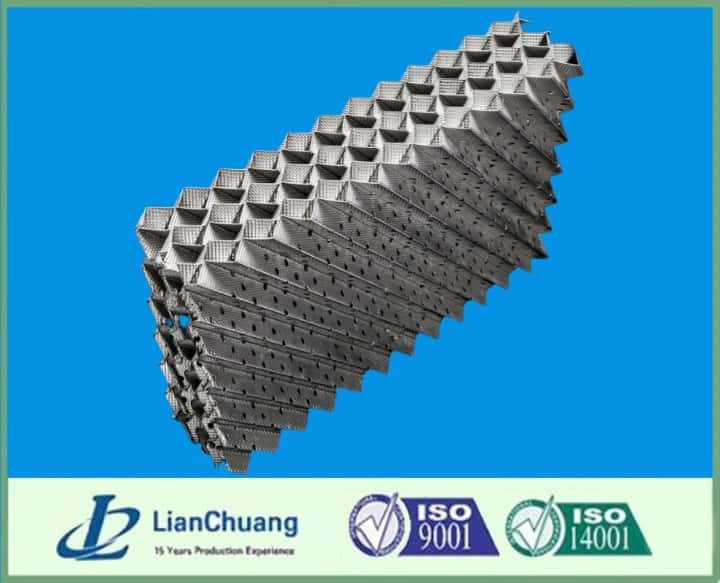

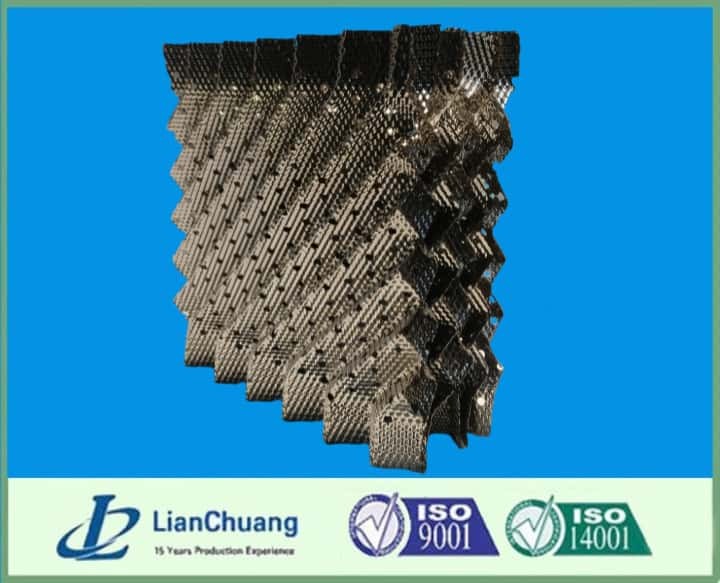

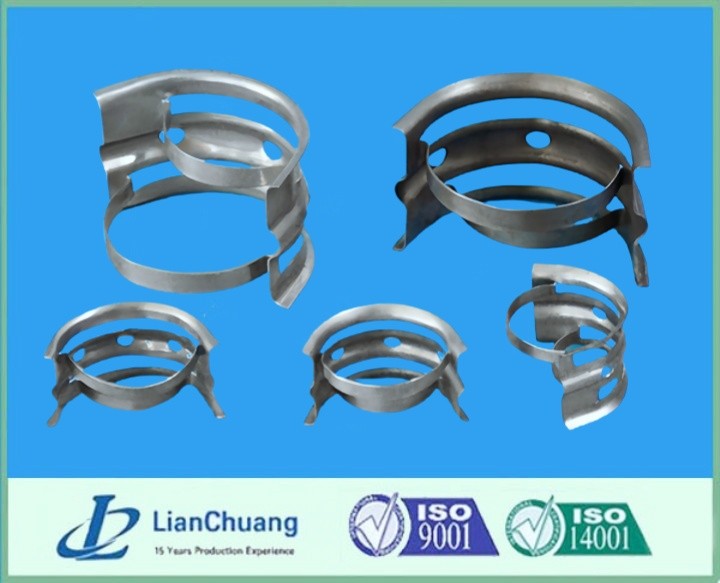

Product Description

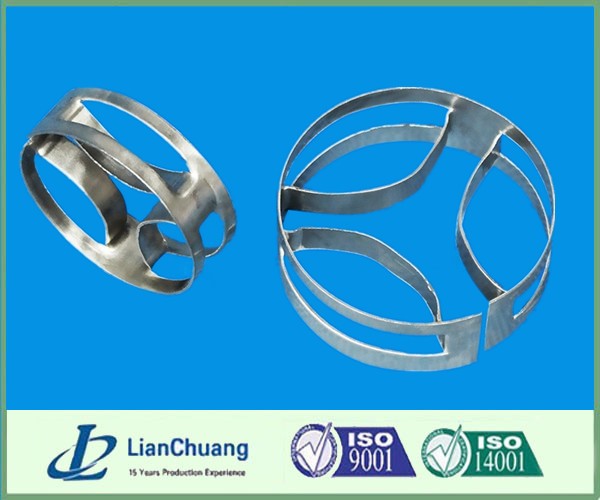

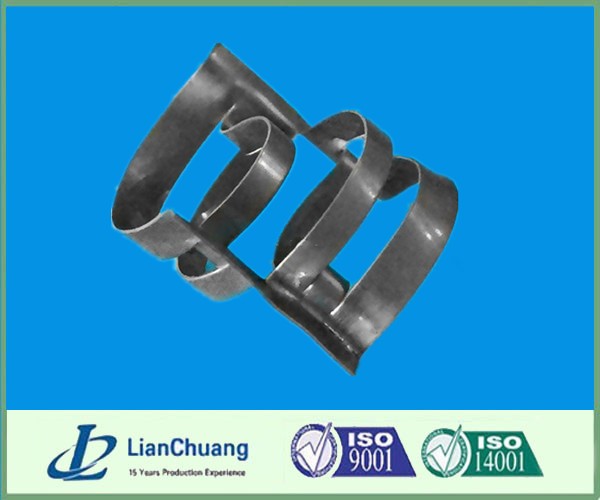

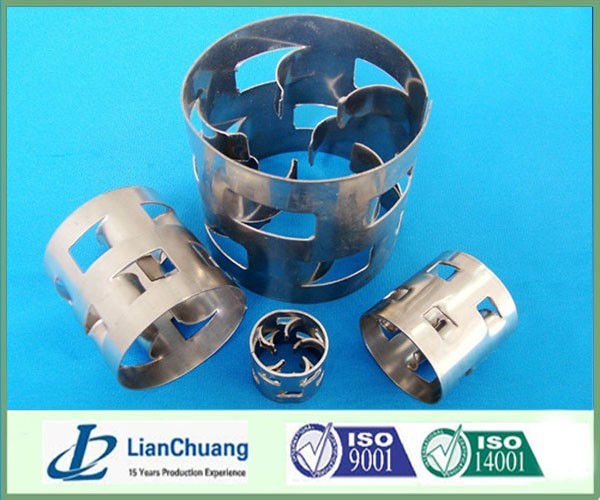

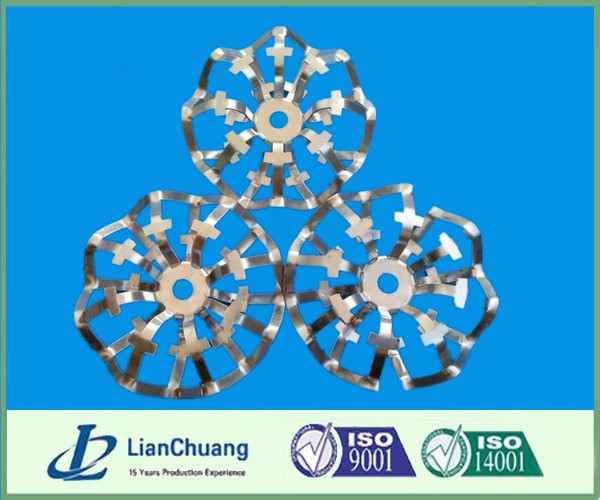

pressing hole ring packing, cannon ring is an kind of efficient packing of small particles, made of metal sheet with equal diameter and height.cannon ring, pressing hole ring packing is mainly used for laboratory and small-volume, high-purity product separation.

And it’s stronger than other experimental filler.The Cannon Ring is a high-performance, carefully designed ring-shaped device widely used in various industrial and research fields, particularly in liquid dynamics and gas flow simulations. With its unique ring structure and innovative design, the Cannon Ring effectively optimizes fluid flow and improves system efficiency. Whether in laboratory research or practical applications, the Cannon Ring offers stable and reliable performance, helping users conduct precise fluid dynamics analysis under extreme conditions.

Key Features:

- Innovative Ring Design: The ring-shaped structure of the Cannon Ring optimizes fluid flow paths and maintains high performance across various flow rates, ensuring even pressure distribution and enhancing experimental accuracy.

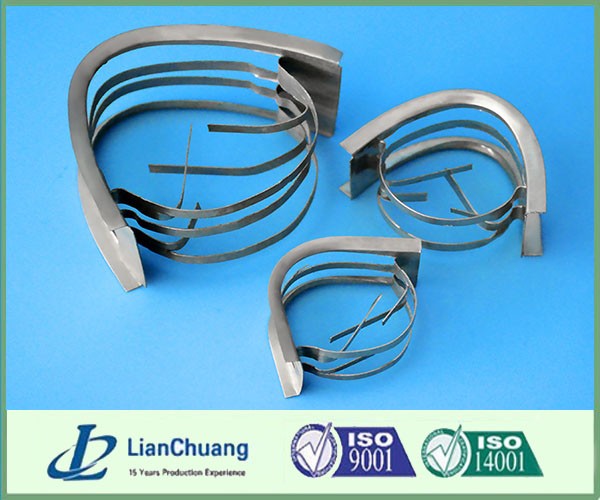

- High Durability: Made from high-quality materials, the Cannon Ring resists corrosion and wear, withstanding extreme environmental conditions and maintaining stable operation even under high pressure or harsh fluid conditions.

- Wide Application: The Cannon Ring is suitable for both liquid and gas flow studies, and is widely used in research experiments, industrial equipment, and fluid dynamics-related research projects.

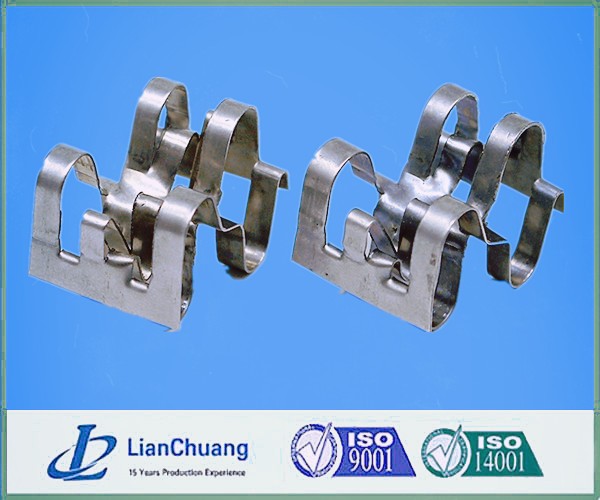

- Ease of Installation and Maintenance: The simple design allows easy installation, disassembly, cleaning, and maintenance, minimizing downtime and improving operational efficiency.

- Highly Customizable: Available in various specifications and material options, the Cannon Ring can be tailored to meet specific application requirements, offering personalized solutions for optimal performance.

Speicification of cannon ring, 304 mesh metallic cannon ring:

Specifications | size | Surface area | Void | Packing density | Theoretical plate number | 80% of the flooding point the pressure drop of gas velocity |

(mm) | (mm) | (m2/m3) | (m3/m3) | (kg/m3) | blocks/m | mm(H2)/m |

2×2 | 2×2×0.1 | 1500 | 0.93 | 570 | 22~23 | 23 |

3×3 | 3×3×0.1 | 1380 | 0.93 | 540 | 20~22 | 30 |

4×4 | 4×4×0.1 | 1340 | 0.93 | 480 | 14.5~15.5 | 147 |

5×5 | 5×5×0.1 | 1029 | 0.94 | 410 | 14~15 | 95 |

6×6 | 6×6×0.1 | 910 | 0.95 | 360 | 12~14 | 86 |

7×7 | 7×7×0.1 | 670 | 0.96 | 290 | 6~7 | 65 |

8×8 | 8×8×0.1 | 540 | 0.97 | 240 | 5~6 | 13 |

9×9 | 9×9×0.1 | 360 | 0.975 | 140 | 5 | 9 |

Applicable Fields:

- Research Institutions: Used in fluid dynamics, thermodynamics experiments, and gas flow simulations.

- Industrial Applications: Suitable for pressure and flow control in petroleum, chemical, and gas pipeline industries.

- Engineering Research: Optimizing flow efficiency in pumping stations, filtration systems, cooling systems, and other equipment.

Conclusion:

The Cannon Ring is a highly efficient, durable, and easy-to-maintain fluid dynamics device, ideal for fluid flow analysis and experiments with high demands. With its innovative ring design, powerful customization options, and broad application scenarios, the Cannon Ring is the perfect choice for numerous industries and research projects.