Product Description

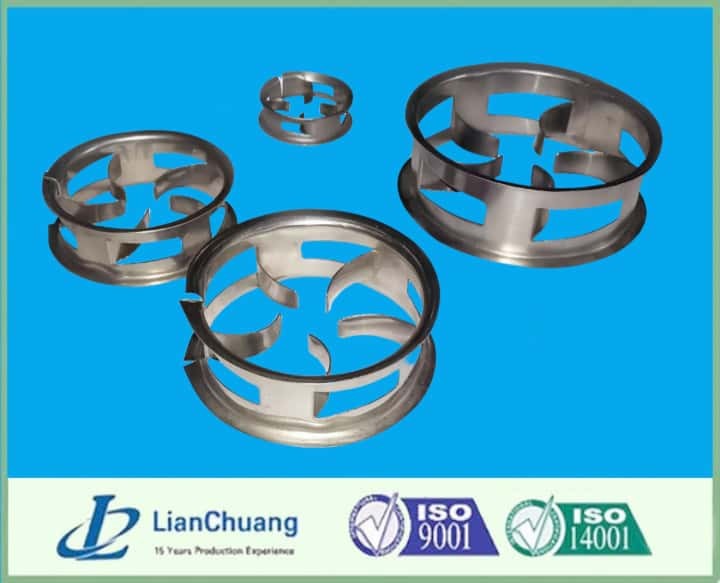

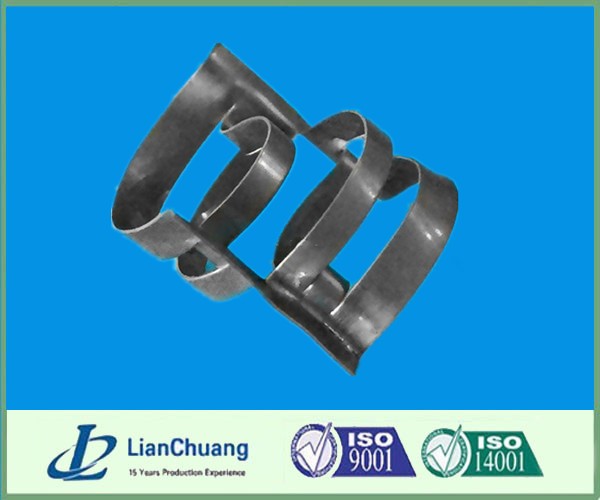

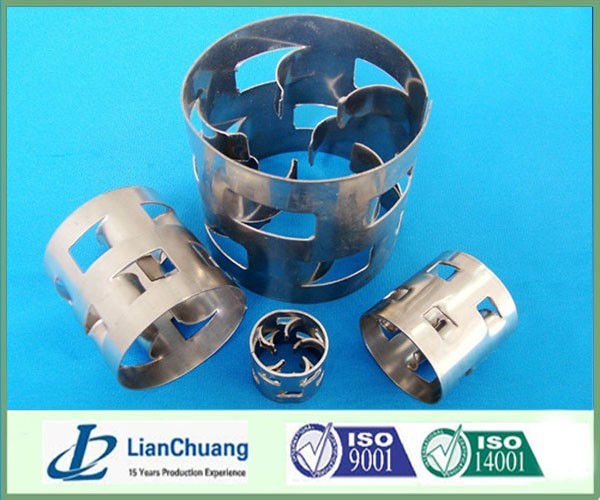

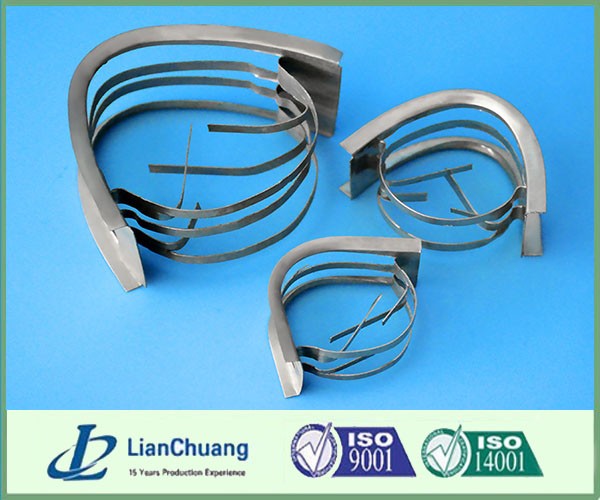

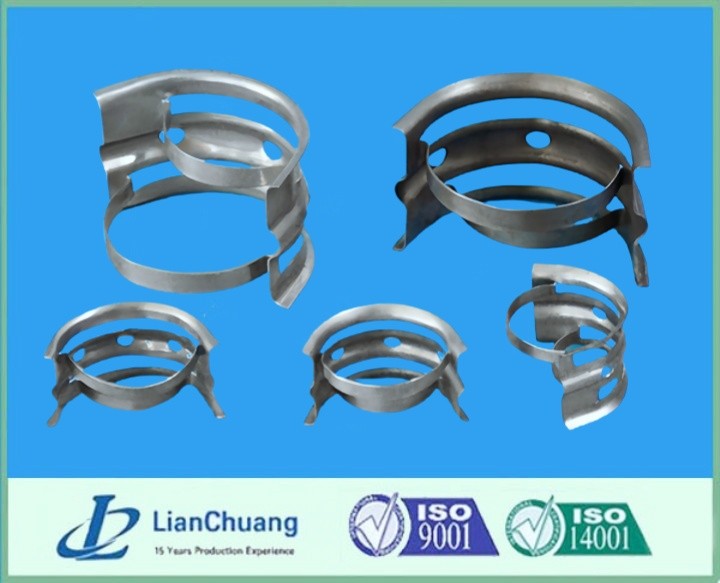

Metal C-ring rrandom packings, also known as metal cascade mini rings, are widely used in a variety of industrial applications, including gas dehydration, glycol absorption, biogas processing, and chemical gas washing. Due to their unique cylindrical shape and vertical alignment, these metal packing materials provide superior gas flow management, low pressure drop, and enhanced hydraulic capacity in packed bed applications.

Key Features of Metal C-Ring Random Packing

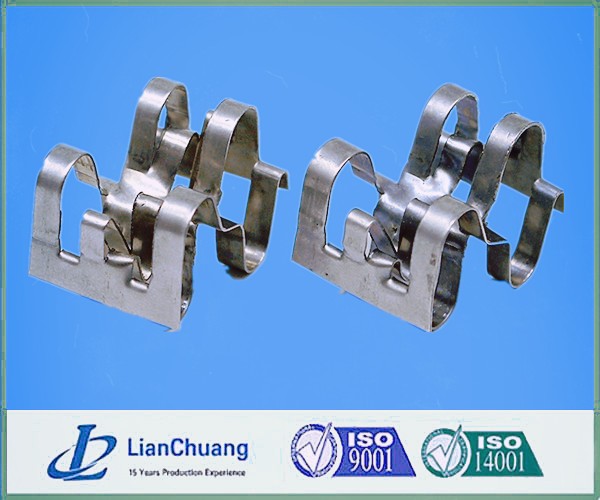

- Optimized Gas Flow and Pressure Drop: The open sides of the Metal C-ring allow unrestricted gas flow, minimizing pressure drop, which is essential for optimizing system performance. This design is particularly advantageous for smaller column diameters and lower fan sizes in new installations, improving overall efficiency.

- Increased Mechanical Strength: Metal C-rings are known for their high mechanical strength, making them ideal for deep packed beds. Their durability allows for the efficient handling of large volumes of fluid, offering higher hydraulic capacity and better mass transfer performance.

- Resistance to Fouling: One of the standout features of Metal C-rings is their resistance to fouling. The combination of their vertical alignment and open-sided design ensures that any solids or contaminants are easily flushed downward, preventing build-up and enhancing long-term performance. This makes them a perfect choice for applications with a high risk of fouling.

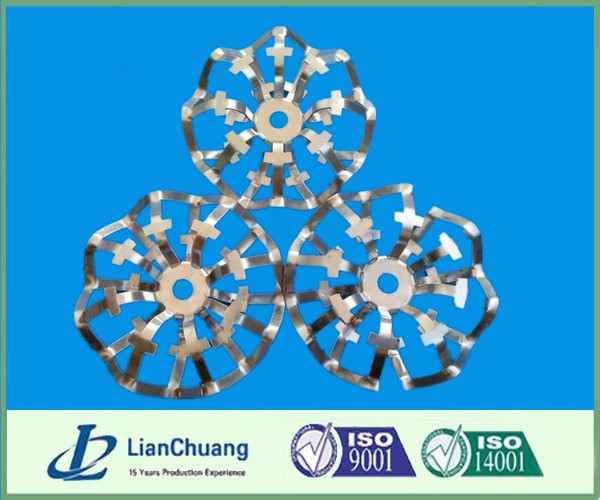

- Improved Mass Transfer Efficiency: In a random packed tower, Metal C-rings form point contacts rather than linear contacts, which increases the liquid film liquidity. This enhances mass transfer efficiency, making them highly effective for a wide range of industrial processes.

Advantages of Metal C-Ring Packing

- Lower tendency to nest, reducing the risk of channeling and dry spots in the packed bed.

- Excellent mechanical strength that supports deep packed beds, suitable for high-capacity applications.

- Resistance to fouling, which extends the life of the equipment and improves operational efficiency.

- Versatile material options, including carbon steel, stainless steel (304, 304L, 410, 316, 316L), copper, and special alloys.

- No minimum order quantities, with full material and quality certifications available.

Applications of Metal C-Rings

Metal C-rings are ideal for a range of industries and processes, including:

- Biogas Washing: Efficient separation and removal of contaminants from biogas streams.

- Chemical Gas Washing: Used to purify gases in chemical processes by removing undesirable components.

- Glycol Absorption: Effective in glycol recovery and purification systems.

- Gas Dehydration: Plays a crucial role in removing water vapor from gas streams, ensuring optimal system operation.

Material Options

Metal C-rings are available in various materials to meet specific operational requirements:

- Carbon Steel: Ideal for standard applications.

- Stainless Steel: Options such as 304, 304L, 410, 316, and 316L for applications requiring corrosion resistance.

- Copper and Special Alloys: Suitable for specialized applications in extreme environments or where specific chemical resistance is needed.